If you’re not promoting your company logo on your workers’ PPE, you’re missing out on a fantastic and highly influential branding opportunity. It’s one of the easiest ways to build brand awareness and confidence – both on and off your worksite.

Is it really worth it to brand PPE?

Since it is often the outermost layer of a worker’s attire, for industries required to comply with safety apparel standards, a workers’ PPE serves as its company uniform and what is often noticed first.

It’s an efficient and effective way to stretch your marketing dollars too, but don’t just take our word for it.

A few years back, a marketing research group surveyed 14 major industry groups, ranging from general building contractors to auto repair services. The majority of respondents (67%) found branding their uniforms was a more effective way of increasing their company’s visibility than other popular sources, including the internet, TV, and radio.

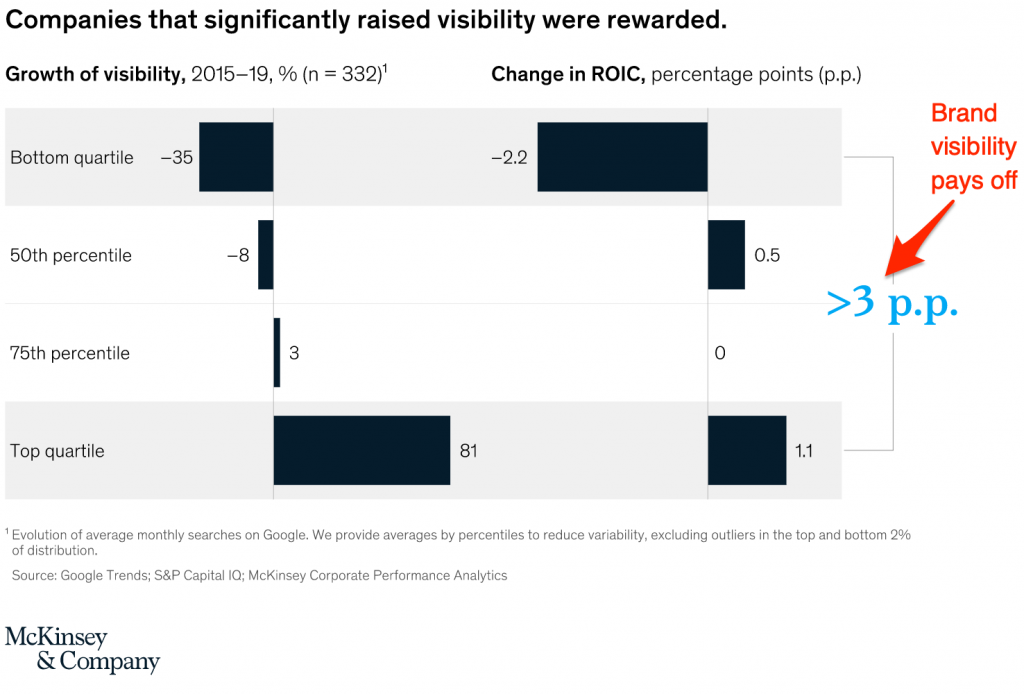

Those survey results still hold today. A 2021 McKinsey report concluded companies that improved brand visibility the most increased return on invested capital (ROIC) by about three percentage points more than those whose visibility declined the most.

Branding ideas for essential PPE

Because so many items can be branded these days, employers have choices on what safety apparel they choose to display their logo on. Branding can be done on items like jackets, shirts, and vests. But you can also put logos on most work gloves, hard hats, and safety glasses.

Below, we’ve put together a list of some popular safety apparel that can easily be branded and usually comes in various colors that will complement your business style. These are only a few ideas of what PPE you might want to brand and where to put your logo. We’re open to your suggestions on logo placement and can help you narrow down your choices.

1. Elevate your brand awareness with your company logo printed on the back of your vests, jackets, and protective apparel. |

|||||||||||||||||||

|

You and your company logo will be seen when you wear a hi-vis vest with your brand presented prominently on the back panel. Or you might prefer a small custom logo placed on the front of your PPE – another great option! | ||||||||||||||||||

|

Hi-vis jackets offer rain and wind protection and create an excellent opportunity to show company pride with an imprint of your custom logo on the back panel. | ||||||||||||||||||

|

Disposable coveralls create the perfect opportunity to get your logo seen and show your company pride. Put your company logo on your disposable protective apparel and increase your visibility. It works well as a giveaway to guests on worksite visits too and makes you look professional as well as compliant. | ||||||||||||||||||

2. Personalize and keep your workers’ hands safe with branded work gloves. |

|||||||||||||||||||

|

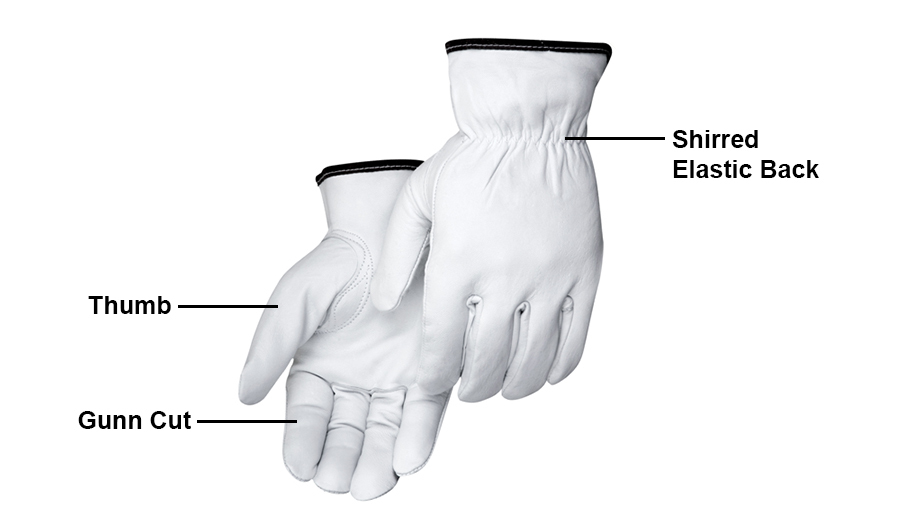

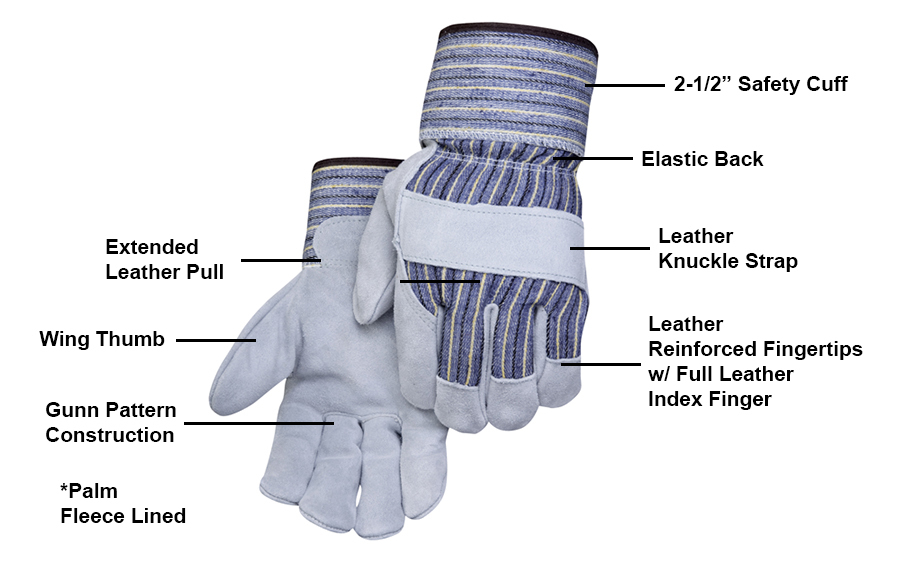

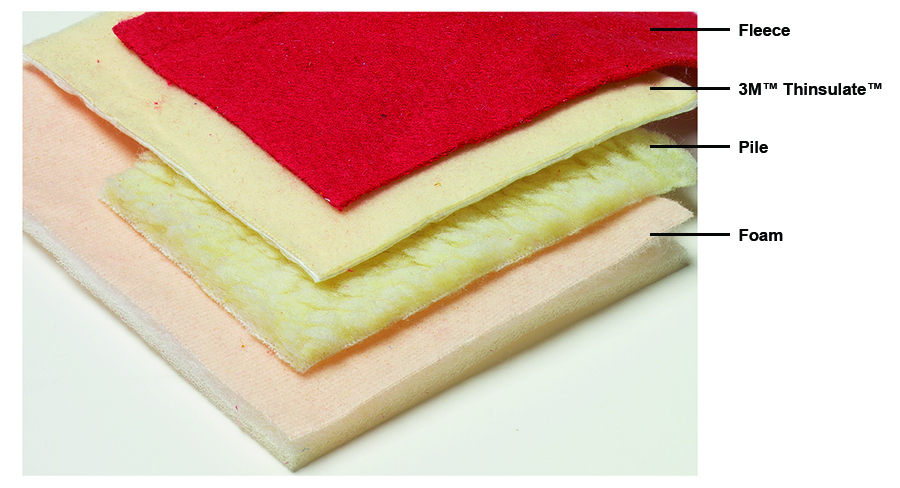

Traditional leather work gloves offer an excellent canvas for printed logos. It’s also a great place to promote safety awareness by imprinting “watch your hands” on the back of the glove or add your own custom logo to either the back or on the safety cuffs for a personal look that will get your brand noticed. | ||||||||||||||||||

|

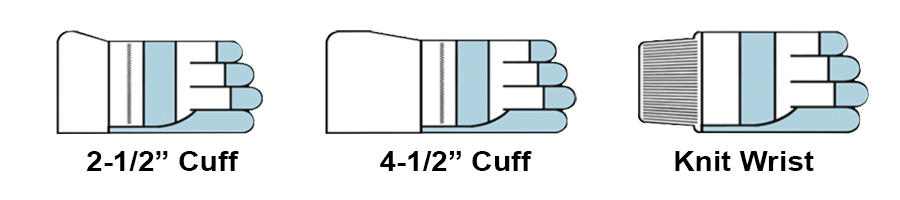

Cotton canvas gloves are ideal for general purpose work, and with a knit wrist cuff, they stay in place while preventing dirt and debris from getting in. Top it off with your logo printed on the back or cuff at a cost-effective price. | ||||||||||||||||||

|

Coated gloves are essential when protecting your hands from abrasions and punctures during the workday. They also present another great opportunity to show off your logo without compromising the glove’s performance. | ||||||||||||||||||

3. Customize your logo on your favorite brand of hard hats or safety glasses. |

|||||||||||||||||||

|

What better way to make sure your logo gets noticed than to put it on your hard hat either in the front or on the back – it’s your choice. The customization shouldn’t stop there either. Make sure your hat fits well as there are different designs and added features to ensure it is comfortable and safe on the job too. | ||||||||||||||||||

|

Your safety specs may not seem like an obvious choice for a logo, but on the side temples and bottom side lens area are fantastic placement to showcase your branding while keeping your eyes protected and ANSI Z87+ compliant too. | ||||||||||||||||||

Now that you’ve decided to stand out from the crowd with branded PPE, the next question is what type of printing will work for you and who should you trust to do it?

Choose a straight-forward printing process that suits the PPE

There are two main processes used when it comes to branding workwear: pad printing and silkscreen printing. Both methods create a well-defined image and can produce a variety of colors. But each technique is used specifically for certain types of PPE to get the best results.

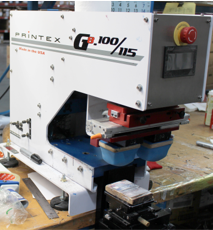

PAD PRINTING

Transferring two-dimensional images onto a three-dimensional object is an offset printing process called pad printing. It requires an etched plate and a pad to transpose the image. Pad printing machines utilize three main components to successfully deliver a print to an object: the plate, the ink cup, and the pad.

First, an image is etched onto the plate. Then the ink cup holds the ink and slides it across the etched plate. This leaves a tiny amount of ink in the etch.

From there, the pad delivers the ink using a soft silicone material that presses and moves it over the underlayer, where it is pressed again to transfer the image.

SILKSCREEN PRINTING

Screen printing is used to print larger images and is one of the most popular printing techniques used for putting logo designs on a variety of products. In most cases, it is a process used with fabrics and paper, but it can be adapted to suit other materials, including wood, ceramics, and plastics.

As the name suggests, the process involves making a screen and then applying ink to the material. The ink is pushed through small holes in the screen, transferring it to the material underneath.

It takes one screen for each color, and by using several screens, you are able to layer different colors – one on top of each other, creating the details in the provided logo or design.

Trust your brand with a recognized leader in safety

It’s not always easy to get branding right. That’s why it’s essential to work with experienced professionals who can offer advice on fabrics and the dimensions and positioning of your logo and help you achieve any special requirements.

At Liberty Glove and Safety, we recognize the importance of your brand so when we are trusted with providing a custom logo – we treat your logo with respect and make sure you have a quality finish. Our in-house branding experts will recommend the best process for your branded PPE and ensure your custom logo stands out, gets noticed, and increases your brand awareness.

So, if your business would like to add a professional value-added look by printing your custom logo on your PPE – get in touch and find out more about all our options.