Much more than just fixing things, Maintenance, Repair, and Operations (MRO) is what keeps things moving. It’s a critical part of the manufacturing industry because a plant or factory or any other type of facility can’t produce if it’s not running.

However, it’s an easy area to take for granted. It is not often noticed when it’s working well, but operations start breaking down if the MRO team falls behind in routine maintenance or repair.

By the end of this post, you will understand the value of MRO and the workers carrying it out every day. We’ll explore the safety challenges, look at four key protections to focus on, and explain why it’s important.

The critical nature of MRO

A Peerless Research Group (PRG) survey on manufacturing reveals a company environment where the MRO and the workers in it play an essential role. For 94% of respondents, MRO is extremely or somewhat important to their companies’ overall operations. Only 6% indicated that MRO was not very important or not at all important.

Respondents that view MRO as “somewhat important” say it helps to reduce downtime, manage preventative maintenance and streamline their plants. Those who see MRO as “extremely” important say it helps their firms maintain customer satisfaction, maintain continuous production, follow lean practices, and secure the “right parts for the first time, every time.”

Safety Challenges in the Industry

Brian Devaney from Sales Solutions, Inc. Is no stranger to the work that goes into MRO. With over 15 years of combined construction, manufacturing, and safety experience, he’s seen many operations first-hand.

As part of his work, he performs job site hazard analysis during his site visits. It often involves advising safety professionals responsible for MRO.

Brian says safety compliance becomes a challenge when the worker doesn’t buy into the safeguards including the usefulness of the PPE. “You get a lack of compliance when the PPE makes it harder for somebody to do their job,” he added.

He said there’s a more important conversation to be had. “We don’t spend enough time talking to the actual user about why they should wear this PPE.”

“A successful hand protection audit means going to the functional areas and getting information from the person doing the job who actually wears the required gloves.” – Brian Devaney

He stresses education and training as part of the overall safety culture in any business.

The Most Frequently Used PPE for MRO Workers

Today, as Brian mentioned, safety compliance has become very important In manufacturing. However, it wasn’t always that way.

In fact, PPE isn’t something that has always been regulated. Its use has been a progression that’s taken place over decades of trial and error, often at the expense of the worker.

Luckily, the days of unchecked and out-of-hand manufacturing injuries along with unsafe practices are in the past. We have safer working environments now than ever before.

To ensure that it stays that way, we have the Occupational Safety and Health Administration (OSHA). OSHA regulates safe practices and PPE use in manufacturing facilities nationwide to ensure that companies and individuals conduct business safely.

OSHA requires that personal protective equipment (PPE) be selected, provided, and worn by employees in situations where PPE could help reduce the potential for harm and injury. That includes MRO workers whether they are internal or external (contractors).

Below are the four most common types of protective gear used in manufacturing facilities to keep MRO workers safe.

Head Protection

According to OSHA, hard hats must be worn on any worksite where there is a risk of objects falling from above. That includes inside a manufacturing facility.

However, the Bureau of Labor Statistics (BLS) shows that only 16% of workers who sustained head injuries wore hard hats even though many were required to wear them.

It’s a grim statistic that shows why workers should wear a hard hat in any areas where they could be struck or hit by fixed, moving, protruding, or falling objects. It’s also a necessary protection when in contact with dangerous levels of electricity or exposed to extreme weather, UV rays, or high temperatures.

In general, most hard hats should be replaced every three years. Manufacturers usually provide specific recommendations.

DuraShell™ Hard Hats

It’s head protection that provides a critical safeguard inside or outside work environments. It has an outstanding fit, comfort, and uncompromising safety.

The DuraShell™ suspension design makes for an easier adjustment by the wearer. And the vertical height adjustment provides a customized fit. Universal accessory slots are built to fit cap-mounted earmuffs and chin straps. It’s a hard hat that is also available in multiple colors and features:

- Polyethylene double layered crown strap

- Replaceable and washable Suspensions

- High-density polyethylene construction

- Low-Profile design

- Pillowed brow pad & top ribbon pad for comfort

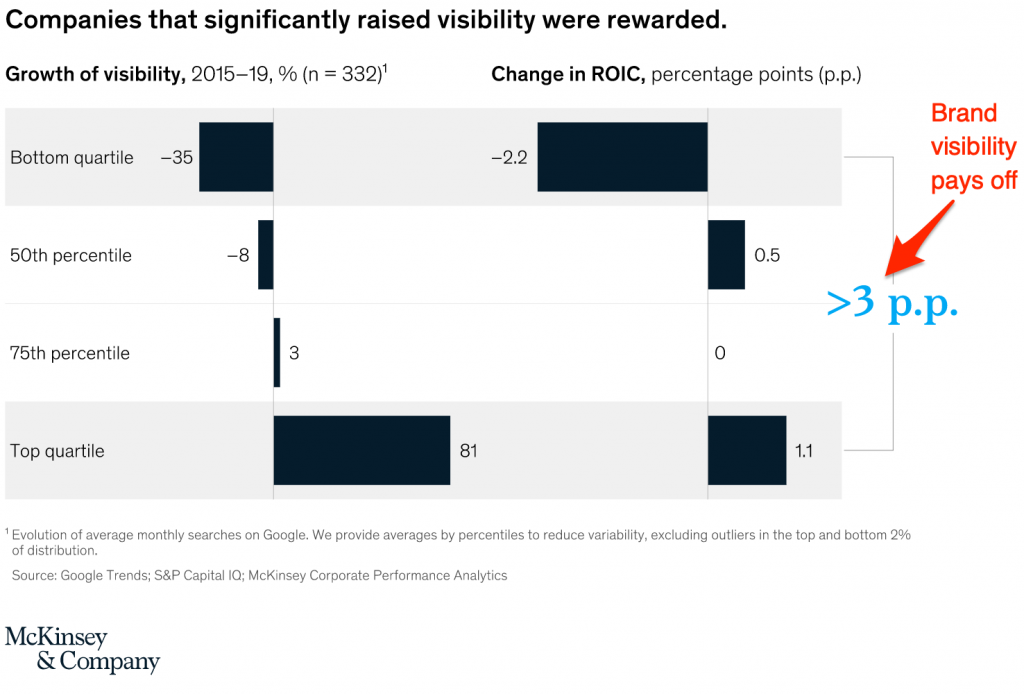

And don’t forget about the importance of your brand on PPE like your team’s hard hats. If your business would like to add a professional value-added look by printing your custom logo, the Liberty Glove and Safety in-house branding experts can help. We ensure your custom logo stands out, gets noticed, and increases your brand awareness.

Hearing Protection

Hearing protection is required in work environments that are exposed to noise levels equal to or greater than 85 decibels (dB) averaged over an eight-hour period. Most manufacturing facilities fit into this category.

OSHA notes that noise may be a problem in your facility if workers report:

- Hearing ringing or humming in their ears when they leave work

- Have to shout to be heard by a coworker an arm’s length away

- Experience temporary hearing loss when leaving work

The OSHA standard 1910.95(b)(1) says that when employees are subjected to sounds over 85 decibels (dB), then administrative or engineering controls should be put in place. If that doesn’t reduce sound levels, then hearing protection needs to be provided to limit the noise.

The best hearing protection is the one that is comfortable and convenient and one that workers will wear every time they are in an environment with hazardous noise.

DuraPlugs™ Ear Muffs

Just like with gloves, ear protection should fit securely and comfortably. Duraplug Ear Muffs work well in a manufacturing environment because they’re lightweight but rugged. The foam filled and padded ear cups are highly effective in keeping noise to a minimum. It’s hearing protection that offers:

- Adjustable nylon headband

- Large soft foam ear cups to fit all sizes

- Lightweight and durable construction

- Noise reduction rating (NRR) 25dB

Eye Protection

The American Academy of Ophthalmology and Eye M.D.s says one million people are affected by an eye injury every year and the Vision council reports 40% of on-the-job eye injuries happen in the manufacturing, construction, and mining industries.

Those are statistics that highlight the need for eye protection for all workers working in manufacturing facilities, often full of sawdust, metal shards, or chemicals hanging in the air.

But it’s not all bad news. The experts at the Prevent Blindness organization say that 90% of eye injuries are preventable using appropriate protective eyewear. It’s one of many reasons safety glasses or goggles are required when operating or working MRO in manufacturing.

iNOX™ F-III™ (amber) and iNOX™ Aura II™ (gray) Safety Glasses

With an amber lens for indoors or a gray lens for outdoors, these safety glasses are versatile eye protection perfect for MRO workers. Simple to slip on and off as needed, they are also durable enough to be tucked in a pocket when not being used. Both pairs feature:

- Polycarbonate temples and single-piece wrap-around lens

- Scratch resistant polycarbonate lens

- Lenses filter 99% of harmful UVA & UVB rays

- Soft rubber nose pads and non-slip rubber temple tips

- ANSI Z87.1-2015 standard certified

Hand Protection

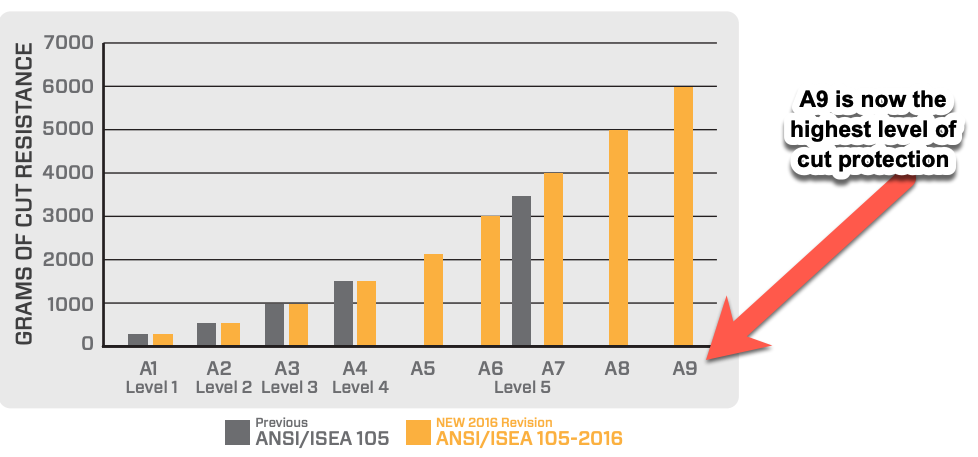

Cuts and other hand injuries are common types of accidents in manufacturing. It’s why a large variety of gloves are available for safely handling most MRO jobs.

However, the Bureau of Labor Statistics reports that 250,000 severe injuries to fingers, hands, and wrists occur yearly. Seventy percent of those workers were not wearing gloves when the injury occurred, and thirty percent were wearing inadequate or inappropriate hand protection.

For the majority of MRO work, a multi-purpose seamless coated glove offers the perfect level of safety. But only if it’s a glove that is comfortable to wear and can handle a wide variety of jobs.

G-Grip™ and P-Grip™ Safety Gloves

Designed for resistance against oily applications and abrasion risks, the G and P-Grip series gloves provide the reliable, flexible type of protection MRO workers need. Made with materials that allow dexterity and comfort, they’re dependably made and used for a wide assortment of applications.

Both offer excellent sensitivity and fit. They also have colored cuffs for easy size identification. And each is durable enough to withstand multiple launderings.

In addition, the G-Grip™ has a nylon/lycra shell, nitrile micro-foam palm coating and provides:

- Cutting edge technology micro-foam coating

- Superior grip and abrasion resistance

- Applicable for both wet and dry applications

The P-Grip™ is a 13-gauge polyester shell glove, which also has:

- Three touch screen fingertips

- Technology advanced polyurethane coating

- Hi-vis green polyester shell

The Future of MRO and a Safe Work Culture

As maintenance, repair and operations evolve to meet current demands and the ongoing changes that come with it, MRO worker safety continues to be an important focus.

“I see the attention to those changes as better for the safety of workers,” Brian said. “We’re coming up with better ways to protect people when they’re doing their job and that’s a good thing.”

Whether it’s gloves, eyewear, head, ear protection, or other PPE, Liberty Glove and Safety offers protective equipment and clothing that’s reliable and resilient. Manufacturing workers including those in MRO can choose from a large range of high-quality brands that cater to the essential gear you need.