Safe workplaces are good business. Without proper compliance with the Occupational Safety and Health Administration’s (OSHA) Personal Protective Equipment (PPE) standards serious risks can be involved for both employers and employees.

OSHA’s aim is to reduce the number of workplace injuries and illnesses. Successful businesses know the OSHA standards applicable to their industry and work environment to ensure a safe workplace.

Companies with a Strong Commitment to Safety Avoid Serious Issues and Penalties

Successful companies focus on OSHA regulations and PPE by investing in comprehensive safety programs, ongoing training, adequate PPE, and a culture of safety.

Without proper compliance with PPE standards, serious risks can be involved for both employers and employees. Specifically, here are some of the biggest issues driving OSHA and PPE compliance:

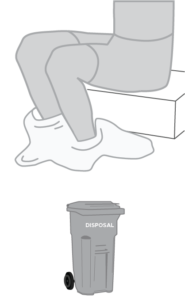

- worker injuries and fatalities

- OSHA fines and penalties

- increased insurance premiums

- legal liabilities and lawsuits

- compliance costs

- keeping up with regulations

PPE is Crucial in Safeguarding Workers from Various Hazards on the Job

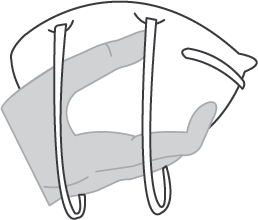

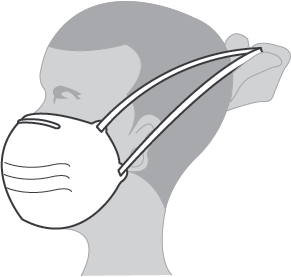

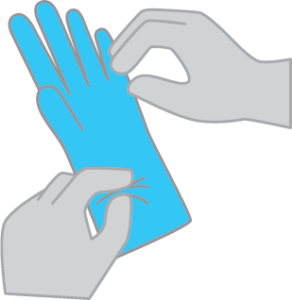

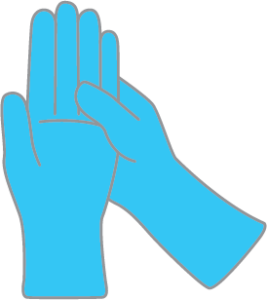

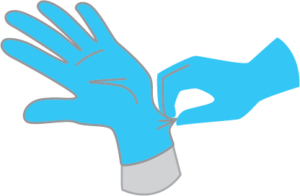

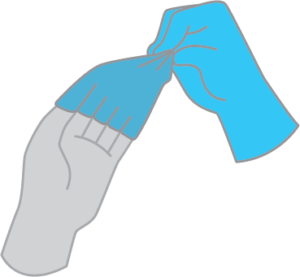

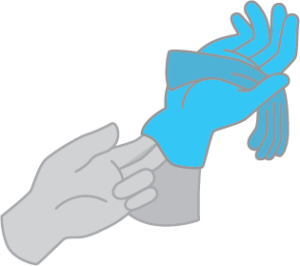

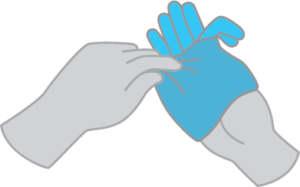

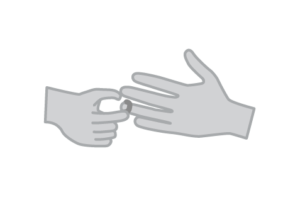

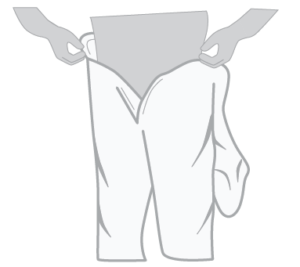

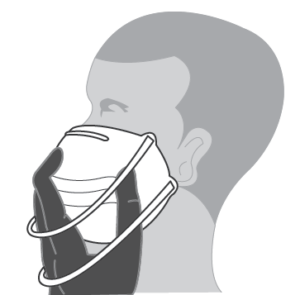

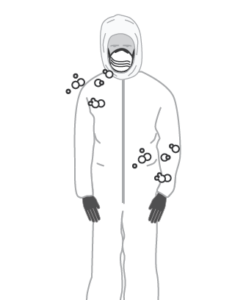

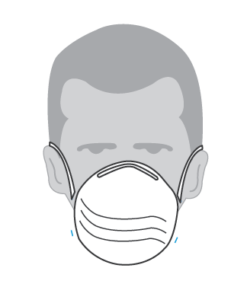

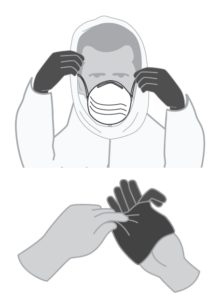

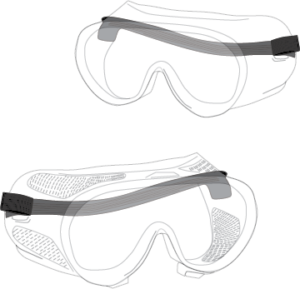

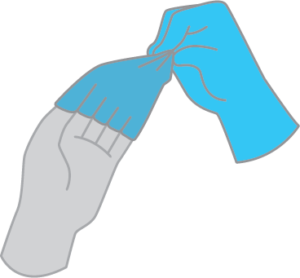

PPE includes any device or appliance designed to be worn or held by an individual for protection against one or more health and safety hazards. Some examples of PPE include cut resistant gloves, coated gloves, sleeves and hi-vis protective apparel.

A Deep Dive into OSHA PPE Requirements and Compliance

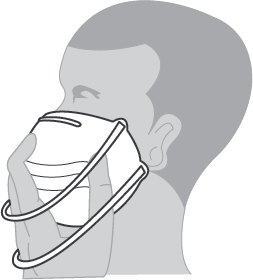

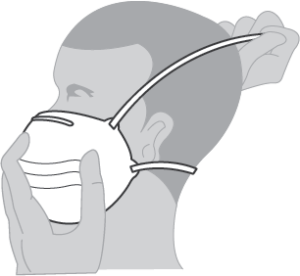

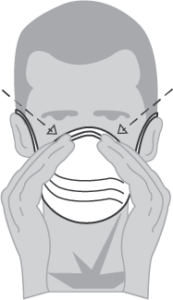

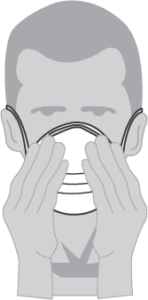

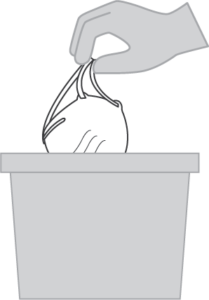

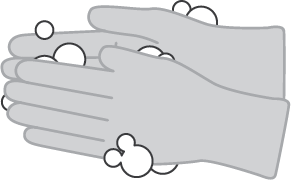

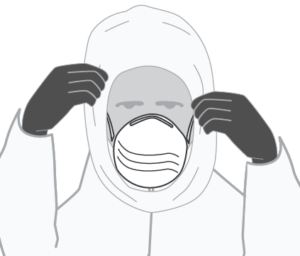

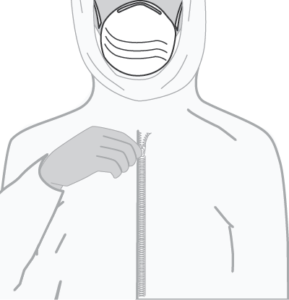

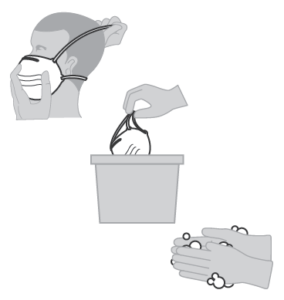

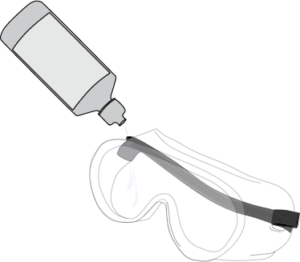

According to OSHA, personal protective equipment must be designed and constructed safely, kept clean and dependable, and fit comfortably to encourage workers to use it. Employers must provide workers with safety gear and ensure it is properly maintained.

How to Ensure Compliance with OSHA PPE Requirements

Implement policies that require using suitable personal protective equipment (PPE), providing training on the correct use of PPE, and regularly enforcing these policies. Display appropriate signage in each work area and train supervisors to monitor PPE usage daily.

Consider progressive discipline for repeat offenders who fail to comply with proper PPE usage. This could include verbal warnings, written reprimands, suspension, and even dismissal in extreme cases.

OSHA’s established PPE regulations have different requirements depending on the specific job tasks and conditions in an industrial workplace.

Employers must ensure workers wear the proper PPE for tasks that could expose them to physical, chemical, electrical, mechanical, or other hazards.

For instance, protective apparel plays an important roles in construction, where workers are exposed to a variety of hazards, including falls, loud noise, dust, and chemicals. Workers must use PPE appropriate for a construction site.

In manufacturing PPE sleeves, cut resistant gloves and coated gloves protect hands and arms from abrasions, cuts, and exposure to harmful substances.

In many industries workers wear hi- vis safety apparel to alert drivers or other vehicle operators of a worker’s presence, especially in low light and dark conditions.

Without a PPE program that includes the provision of items like safety harnesses, masks, and gloves, as well as training on how to use them, workers would be at high risk of injury or illness.

OSHA has Identified Six Types of Violations, each Carrying Different Fines

OSHA enforces its standards by conducting inspections in order of priority, which includes imminent danger situations, fatalities, and worker complaints. Employers must adhere to OSHA safety requirements to avoid costly fines and other sanctions.

OSHA does not fine employees for workplace safety violations; the responsibility lies solely with the employer. Fines collected by OSHA do not directly fund the agency. Instead, they are directed to the U.S. Treasury’s general fund. Importantly, these fines are not tax-deductible.

OSHA’s six types of violations:

| Type of Violation | Minimum Penalty | Maximum Penalty |

| Serious | $1,036 | $14,502 |

| Other-than-serious | $0 | $14,502 |

| Willful or Repeated | $10,360 | $145,027 |

| Posting Requirements | $0 | $14,502 |

| Failure to Abate | N/A | $14,502 per day past the abatement date |

| De Minimis | N/A | N/A |

Helpful Definitions of OSHA’s Six Types of Violations

Serious violations occur when an employer knowingly leaves a hazard that could result in death or serious harm unresolved. Fines can reach up to $14,502 per violation.

Other-than-serious violations don’t lead to serious injury or death but compromise employee safety. Fines can reach up to $14,502 per violation, though they can be reduced by up to 95%.

Willful or repeated violations are those that are repeated within three years, and companies face much harsher penalties, from $10,360 up to $145,027 per violation. The size of the workforce can lead to a reduced fine, with an 80% reduction for 10 or fewer employees, decreasing to no reduction for 251 or more employees.

Posting requirements violations occur if an employer receives a citation or violation notice from OSHA. The notice must be visibly posted near the incident area until the violation is resolved or for three days. Failure to do so may result in fines up to $14,502 per violation.

Failure to abate violations happens if companies do not resolve a safety violation by the date specified in the OSHA notice. The company can be fined up to $14,502 per day past the abatement date.

De minimis violations are minor infractions that don’t necessarily require a citation or notice, and they typically don’t incur penalties.

Have questions? Contact Liberty Safety’s PPE experts now.

The Top 10 Most Cited OSHA Violations in 2022 were:

- Fall protection

- Hazard communication

- Ladders

- Respiratory protection

- Scaffolding

- Lockout/Tagout

- Powered industrial trucks

- Fall protection – training requirements

- Personal protective and lifesaving equipment – eye and face protection

- Machine guarding

Learn more about how these top most cited OSHA violations impact your PPE choices.

What to Include when Creating your PPE Program

The OSHA PPE standards require employers to provide employees with personal protective equipment when necessary to protect them from workplace hazards.

To ensure the successful implementation of PPE based on OSHA’s regulations and guidelines, employers should follow these tips:

● Examine the workplace and determine what hazards exist

● Choose and maintain the appropriate PPE for each hazard

● Provide OSHA PPE training to employees

● Monitor compliance regularly

● Enforce policies on PPE use

● Keep employees informed of any changes to PPE policies

Learn how PPE hazards are addressed in specific standards for the construction industry. Have questions about PPE for your industry? Contact Liberty Safety’s PPE experts now.

Ensuring PPE Compliance in the Workplace

PPE, often the last line of defense against occupational hazards, minimizes exposure to various risks, ranging from biological and chemical to physical and ergonomic. Its importance, however, can be overlooked by employees for a myriad of reasons, including discomfort and inconvenience.

Prioritizing Comfort and Convenience in PPE Selection

Don’t let workplace safety be compromised due to these concerns. Organizations should strive to ensure that their PPE is not only suitable for the hazards present but also comfortable and convenient for employees to use.

Involving workers in the selection process of PPE, considering their comfort, ease of use, and even their aesthetic preferences is one way to increase use and safety.

Going Beyond Equipment: The Need for Proper PPE Training

Moreover, effective PPE compliance goes beyond equipment provision – it requires proper training for employees on the use, necessity, and limitations of their PPE. It’s essential to make PPE training engaging and valuable for workers, emphasizing its role in protecting their health and safety.

Creating a Culture of Safety with PPE

Establishing a culture of safety in the workplace is a crucial part of PPE compliance. The success of PPE programs doesn’t just rely on having the right equipment or even stringent regulations in place; it also depends on the willingness and cooperation of employees to use PPE correctly.

When employees feel comfortable discussing PPE and reporting issues, they’re less likely to overlook the potential hazards in their work environment. And, a safe environment contributes to employee retention and productivity.

To this end, one noteworthy program is the OSHA’s Safe and Sound Campaign. The program highlights three main aspects:

- management leadership

- worker participation

- proactive hazard control

Management leadership demonstrates commitment to safety and the well-being of employees.

Workers, when involved in safety programs, are more likely to adhere to safety protocols, and proactive hazard control shifts focus from reaction to prevention.

Have questions? Contact Liberty Safety’s PPE experts now regarding resources available from agencies like OSHA that guide PPE compliance standards.

Maintaining PPE Compliance in the Face of Emerging Threats

Changes in work environments, advancement of technologies, shifts in the global landscape, or unexpected natural disasters can all contribute to new and complex hazards that demand innovative safety measures.

Is your PPE program flexible, adaptive, able to respond to evolving threats and shifting regulations? Regular reviews and updating risk assessments, done ongoingly, identifies new threats as they arise. Ask Liberty Safety about the latest industry developments and update your PPE needs accordingly.

The Future of PPE and Technology

Advancements in technology such as smart PPE are already making their way into various industries. Smart PPE refers to equipment that is connected to the internet and has advanced capabilities, such as real-time hazard tracking and health monitoring. These proactive (rather than reactive) measures can drastically improve safety.

As a leader in the safety industry, Liberty Safety is dedicated to providing head-to-toe PPE that complies with the highest standards and integrates the latest technology. We understand that PPE compliance is a dynamic process that requires constant adaptation and evolution.

Here is a selection of our products that meet the highest standards established by federal agencies. Contact our PPE experts today for the right PPE for your industry and hazards.