Emergencies and disasters can strike unexpectedly, posing significant risks to workplace safety and operations. Employers and workers alike must be prepared to respond effectively to these events. Proper planning and proactive measures are crucial for mitigating risks and ensuring a swift and coordinated response.

According to injuryfacts.nsc.org, in 2022, 69,473 weather events resulted in 813 deaths and 1,718 injuries. Equipping your team with the proper PPE can make a significant impact on emergency response and preparedness when disaster strikes.

Understanding Emergency Preparedness

Emergency preparedness involves preemptive actions taken to anticipate, prevent, mitigate, respond to, and recover from emergencies or disasters. These can vary from natural disasters like earthquakes and hurricanes to human-made incidents like fires, chemical spills, or industrial accidents. A well-structured emergency preparedness plan is essential for safeguarding employees, minimizing disruptions, and facilitating a prompt return to normal operations.

Key Components of Effective Emergency Preparedness

- Risk Assessment and Planning: The first step in emergency preparedness is conducting a thorough risk assessment. This process involves identifying potential hazards specific to your workplace, evaluating their likelihood and potential impact, and developing tailored strategies to mitigate these risks. A comprehensive plan should encompass evacuation procedures, sheltering protocols, communication strategies, and provisions for medical assistance.

- Emergency Response Team: Designating and training an emergency response team is critical to executing the emergency plan effectively. These individuals are pivotal in coordinating response efforts, ensuring adherence to safety protocols, and guiding employees during emergencies. Regular drills and simulations are essential for reinforcing preparedness and enhancing the team’s proficiency in crisis management.

- Communication Protocols: Establishing clear communication channels is paramount during emergencies. Defined protocols ensure that critical information reaches all stakeholders promptly, including employees, emergency responders, and relevant authorities. Implementing emergency notification systems, establishing assembly points, and maintaining updated contact lists are essential components of effective communication strategies.

- Accessibility to Emergency Equipment and Resources: Access to essential emergency resources is vital for swift and effective response actions. This includes maintaining well-stocked first aid kits, fire extinguishers, emergency lighting, evacuation maps, and appropriate Personal Protective Equipment (PPE) tailored to specific hazards. Regular maintenance and inspections ensure the readiness and functionality of these resources.

- Training and Education: Educating employees on emergency procedures, potential risks, and the proper use of emergency equipment is crucial for fostering a safety-conscious workplace culture. Regular training sessions reinforce knowledge and skills and instill confidence among employees in responding to emergencies. Psychological first-aid training should also be included to support employees’ mental well-being during and after crises.

The Role of Personal Protective Equipment (PPE)

During emergencies, PPE plays a pivotal role in safeguarding employees from hazards such as fires, chemical exposures, or falling debris. Ensuring that employees have access to appropriate PPE and are proficient in its use enhances their safety and minimizes the risk of injury or exposure during emergency response activities.

Types of PPE and Their Importance:

- Flame-Resistant Clothing: In environments prone to fires or explosions, flame-resistant (FR) clothing protects against thermal hazards. These garments come in two styles: Primary Flame-Resistant (FR) and Secondary Flame-Resistant (FR).

- Primary FR Garments: Designed to protect against direct and prolonged exposure to flames and thermal hazards.

- Secondary FR Garments: Designed to be worn over primary FR garments, responding to fire in a way that doesn’t negatively affect the performance of the primary FR garment when worn together as an ensemble.

To ensure that flame-resistant (FR) clothing offers adequate protection, it’s crucial to choose the appropriate type based on the exposure level and specific work tasks. This involves assessing workplace operations, processes, or environments that may present a flame or thermal hazard.

- Chemical Protective Clothing: When handling hazardous chemicals or in the event of a chemical spill, appropriate chemical-resistant clothing, such as suits, gloves, and boots made from materials like neoprene or PVC, shields workers from harmful substances. This PPE guards against skin contact and potential absorption of toxic chemicals, reducing the risk of chemical burns or respiratory issues.

To ensure that chemical protective clothing offers adequate protection, it’s crucial to choose the appropriate type based on the exposure level and specific work tasks. This involves assessing workplace operations, processes, or environments that may present a chemical hazard.

- High-Visibility Safety Apparel: During emergency response operations, visibility is paramount to ensure worker safety, especially in low-light conditions or near moving vehicles. High-visibility safety apparel featuring reflective stripes and fluorescent colors enhances worker visibility, minimizing the risk of accidents and improving coordination among emergency responders.

Learn more about High-Visibility Safety Apparel and the ANSI/ISEA 107-2020 standard here.

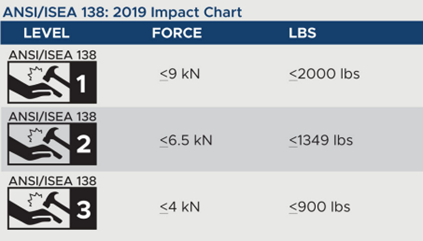

- Head Protection: Helmets or hard hats are essential PPE in environments where falling debris poses a hazard. These protective headgear items absorb impact and prevent head injuries, ensuring workers can perform tasks confidently without fearing head trauma during emergencies.

- Respiratory Protection: Respiratory protection is critical in environments with airborne contaminants, such as smoke, dust, or chemicals. Respirators equipped with filters provide clean air to workers, protecting their lungs from inhaling harmful particles and gases during emergency response activities.

To ensure that respirators offer adequate protection, it’s crucial to choose the appropriate type based on the exposure level and specific work tasks. This involves assessing workplace operations, processes, or environments that may present a respiratory hazard.

July Product Promo – Protecting Against Emergencies

Gear up your workforce with the proper Emergency Preparedness PPE and ensure their well-being on the job. Explore our July Product Promo featuring workwear essentials to keep your team safe.

Conclusion

Emergency preparedness is not just a regulatory requirement but a proactive strategy supporting organizational resilience and employee well-being. By prioritizing comprehensive planning, continuous training, and access to essential resources, businesses can effectively mitigate risks and enhance their readiness to respond to emergencies.

At Liberty Safety, we are dedicated to supporting your safety initiatives with top-quality PPE solutions. Contact us today to learn how we can help your organization stay prepared and protected in emergencies.

Your safety is our priority. It’s all part of our Freedom in Full Gear Promise!