Hand-impact injuries pose unique challenges in treatment and recovery, particularly when any of the hand’s 27 bones are crushed instead of cleanly broken. Beyond bone injuries, these accidents can also harm muscles, tendons, and ligaments (ohsonline.com).

The Occupational Health & Safety (OH&S) states that 42% of acute hand injuries are attributed to impacts. This underscores the importance of selecting the appropriate impact gloves tailored to the specific work task.

What are Impact-Resistant Gloves?

Impact-resistant Gloves are essential personal protective equipment (PPE) designed to prevent occupational hand injuries. These injuries often occur in environments where there’s a high risk of hand trauma from collisions with machinery, heavy equipment, or similar hazards. Reinforcement across the back of the hand, often using Thermoplastic Rubber (TPR), adds an extra layer of defense with a tread design for added protection.

What causes a Hand-Impact Injury?

A hand-impact injury occurs when an object strikes or pinches a hand, transferring force from the object to the hand. The intensity of this force results in a shift or displacement of skin, bones, and muscles, leading to injuries such as lacerations, bone fractures, and bruises.

Understanding the ANSI/ISEA 138-2019 Industry Standard:

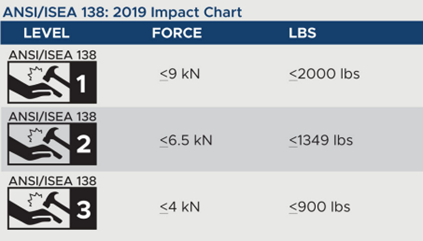

The ANSI/ISEA 138-2019 standard, established by the American National Standard Institute, outlines the minimum performance, classification, and labeling requirements for gloves designed to protect the knuckles and fingers/thumb from impact. The standard classifies impact resistance into three performance levels: level 1, 2, and 3, with level 3 offering the highest level of protection.

The classification is achieved by dropping a ‘drop striker’ on the glove’s impact points, recording the force transferred in kilonewtons (kN). The tests are conducted on each knuckle, finger, and thumb. The knuckles are tested four times, while the fingers and thumbs are tested five times.

The chart below illustrates all impact levels, ranging from Level 1 to Level 3, helping workers choose gloves based on their specific needs.

How Impact-Resistant Glove Materials Safeguard Against Injuries:

To mitigate impact injuries, the key lies in extending the duration over which the impact occurs. This prevents the hand from absorbing the entire impact at once. The primary way to achieve this is through deformation.

Deformation, the impact-resistant material’s ability to temporarily change shape, slows the impact force transferred to the hands. This is achieved by integrating impact-resistant back-of-hand materials, often referred to as bumpers. Bumpers aim to optimize deformation so the impact force is slowed as much as possible.

TPR stands out as a widely used material for impact protection. It possesses shock-absorbing properties and is highly durable for bending, stretching, and moving. This ensures workers maintain a comfortable range of motion while being shielded from impacts. TPR’s versatility extends to performing well in cold and hot working environments.

Choosing the Right Impact-Resistant Glove:

Selecting the right impact-resistant glove involves considering the task at hand and the potential hazards of the job. The chart above serves as a general guide to help you make this determination. For personalized guidance and support, reach out to a Liberty Safety representative to get connected to one of our product experts.

February Product Promo:

Gear up for a safe February with our monthly product promo featuring highlighted items from our impact-resistant gloves line. Explore the features that set these gloves apart.

🔍 Request a Personalized Quote

Your Safety is our priority. It’s all part of our Freedom in Full Gear Promise!