What Risks Do Workers Face in Food Manufacturing?

Recent interest in protecting workers from the COVID 19 virus has brought increasing public attention to food manufacturing and the workers in the industry. Although the pandemic continues to be a safety consideration, paying attention to the workers’ general health and safety must also be a priority.

From extreme temperatures to slips and falls, food manufacturing presents many risks to those in it. In this post we’ll take a closer look at those risks and their impact on the food-manufacturing workers by exploring the following:

- Who are the food manufacturing workers?

- What hazards do they face?

- What are some shared risks and how are they minimized?

- Does the Coronavirus still remain a concern?

Who are the food manufacturing workers?

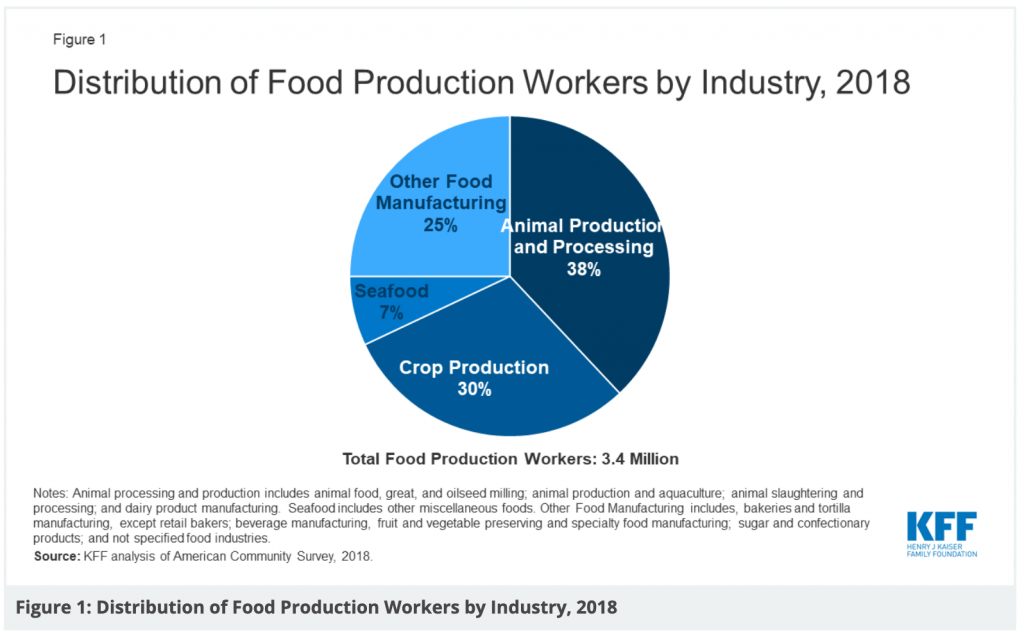

According to a survey by the Kaiser Family Foundation, the most significant portion of food manufacturing workers are in animal production and processing (38%). The subsequent largest set work is crop production (30%) and then seafood (7%). The rest (25%) are part of other food processing facilities.

That represents about 3.4 million people. Taking care of them has a major impact on their health and happiness and is also critical in maintaining our national food supply.

What hazards do they face?

The Occupational Safety and Health Administration (OSHA) and the Center for Disease Control and Prevention (CDC) identify risks within each of the above industries.

Animal Production/processing

There are many serious safety and health hazards in the meatpacking industry. OSHA records hazards that include exposure to high noise levels, dangerous equipment, slippery floors, musculoskeletal disorders, and hazardous chemicals (including ammonia that is used as a refrigerant).

Crop Production (Farmworkers)

According to OSHA, agricultural operations put farmworkers at high risk for fatalities and injuries, work-related lung diseases, noise-induced hearing loss, skin diseases, and certain cancers associated with chemical use and prolonged sun exposure.

Seafood Processing

The CDC reports that seafood processing workers have the highest injury/illness rate of any U.S. maritime workers. Occupational hazards include exposures to biological aerosols containing allergens, microorganisms, and toxins; bacteria and parasites; excessive noise levels; low temperatures; poor ergonomics; and contact with machinery and equipment.

Other Food Manufacturing

An Industry Safety & Hygiene News (ISHN) article, pointed out the importance of upholding safety standards within all of the sectors of the food manufacturing industry. The article stressed that ensuring the workers are looked after and food manufacturing environments are secure is crucial to the overall industry success.

What are some shared risks and how are they minimized?

Each of the mentioned food manufacturing industries shares common risks. Those risks, along with the protective equipment that is often used to minimize them, include:

1. Temperature Extremes

Temperatures play a significant role in a food processing worker’s day. They are often exposed to extreme heat from equipment like ovens, cookers, steamers, and hot water scalders. On the other hand, those workers who work in cold environments face overexposure to low temperatures commonly found in areas that have walk-in freezers, outdoor loading docks, refrigerated trucks, etc.

For cold indoor areas, thermal gloves and hats, earmuffs, and waterproof boots are often used for protecting workers against those temperatures.

For hot indoor environments, OSHA encourages water, rest, and limited exposure as well as treating any heat-related illness quickly.

2. Dangerous Equipment

The tools used in food manufacturing facilities can be hazardous, including equipment like blades, knives, and cutting machines, which put workers at risk of minor to severe injuries often involving the hands. For those workers, wearing cut-resistant gloves is considered critical PPE and can substantially minimize the risks.

Another consideration for those working around food processing equipment is their hair. It’s critical to keep it contained when on the job. Hair can contaminate sanitized surfaces and is a threat to the worker if it gets caught in machinery.

Hair coverings, including hairnets, beard nets, and bouffant caps, are designed to prevent that danger and are required by the FDA

3. High Noise Levels

The noise around many of the machines used in food manufacturing is often at very high levels. Sometimes it is at such a level that it can cause serious adverse effects on the hearing of the workers operating the machines or even just those near them.

Apart from mitigating noise levels, OSHA (in most cases) requires supplying appropriate hearing protection, which may include disposable earplugs or full coverage ear muffs depending on the noise exposure and the chances of hearing loss.

Note that it’s essential to choose the appropriate attenuation level so that alarms and warnings can be heard.

4. Chemical or Biological Exposure

Food processing may, at times, require the use of dangerous biological or chemical substances that could harm those workers who are regularly exposed to them. For example, handling live animals or raw meat (or meat by-products) is a common biological hazard, while sanitizing and cooling food products poses a significant chemical threat.

Coveralls, aprons, goggles, gloves, particulate respirators, and face shields are some of the protections that are necessary to keep workers safe and protect them from the long-term effects of these types of chemical or biological exposures.

5. Slips, Falls, and Trips

Food manufacturing facilities require frequent wash downs. The liquid cleaners needed to keep those surfaces and floors sanitary often create the perfect environment for potential slips or falls.

The last survey by the Bureau of Labor Statistics in 2019 reported that 4,990 workers in the food industry experienced nonfatal injuries involving days away from work caused by these types of accidents.

According to OSHA, employers should implement a comprehensive safety program to identify hazards leading to slips, trips, falls, and other injuries. Of course, proper PPE should be part of that, including footwear with slip-resistant soles

6. Ergonomic risk factors

Workers in the food processing industry could be susceptible to injuries caused by repetitive motion or lifting heavy objects. Those who want to work without the undue pain it can cause will sometimes turn to ergonomic products that may help stabilize their joints when under stress.

Anti-vibration gloves, back support belts, and knee pads, though not required, are examples of products that may provide ergonomic support and offer a more relaxed way of working.

Does the Coronavirus (COVID-19) still remain a concern?

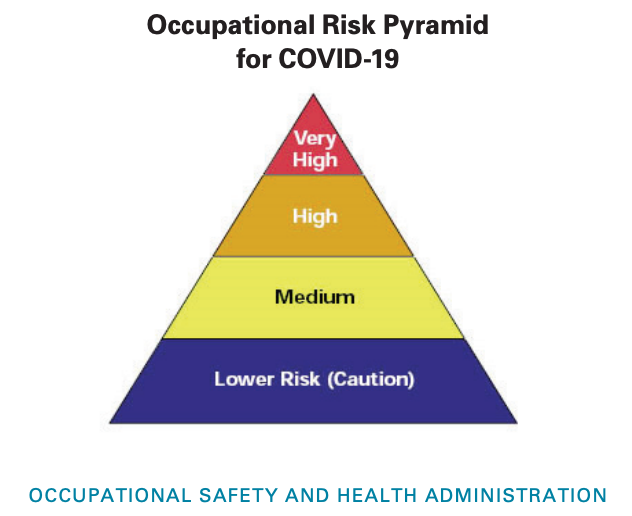

Outside of the industry risks we’ve mentioned, Covid 19 continues to be a safety concern for all food manufacturers. To help employers determine appropriate precautions, OSHA has prepared a guideline entitled: the Guidance on Preparing Workplaces for COVID-19.

The guide divides job tasks into four risk exposure levels. Most American food manufacturing workers will likely fall in the lower exposure risk (caution) or medium exposure risk levels. It’s broken down as the following:

Caption: The Occupational Risk Pyramid shows the four exposure risk levels in the shape of a pyramid to represent the probability distribution of risk.

Very High Exposure Risk

Very high exposure risk jobs are those with high potential for exposure to known or suspected sources of COVID-19 during specific medical, postmortem, or laboratory procedures. Workers in this category include:

- Healthcare workers (e.g., doctors, nurses, dentists, paramedics, emergency medical technicians)

- Healthcare or laboratory personnel collecting or handling specimens from known or suspected COVID-19 patients

- Morgue workers who perform autopsies, on the bodies of people who are known to have, or suspected of having, COVID-19 at the time of their death.

High Exposure Risk

High exposure risk jobs are those with high potential for exposure to known or suspected sources of COVID-19. Workers in this category include:

- Healthcare delivery and support staff (e.g., doctors, nurses, and other hospital staff who must enter patients’ rooms) exposed to known or suspected COVID-19 patients.

- Medical transport workers (e.g., ambulance vehicle operators) moving known or suspected COVID-19 patients in enclosed vehicles.

- Mortuary workers involved in preparing (e.g., for burial or cremation) the bodies of people who are known to have, or suspected of having, COVID-19 at the time of their death.

Medium Exposure Risk

Medium exposure risk jobs include those that require frequent and/or close contact with (i.e., within 6 feet of) people who may be infected with SARS-CoV-2, but who are not known or suspected COVID-19 patients. (e.g., schools, high-population-density work environments, some high-volume retail settings).

Lower Exposure Risk (Caution)

Lower exposure risk (caution) jobs are those that do not require contact with people known to be, or suspected of being, infected with SARS-CoV-2 nor frequent close contact with (i.e., within 6 feet of) the general public. Workers in this category have minimal occupational contact with the public and other coworkers.

The Centers for Disease Control and Prevention (CDC) advises those working in the lower risk category to use face masks or coverings to slow the spread of the virus and help people who are unaware they have the virus from spreading it to others.

In collaboration with the CDC, the FDA developed a quick reference guide to respirators, masks, or cloth face coverings potentially worn by workers in the Food and Agriculture Sector.

Continuing to Keep Workers Safe

Even with a possible end to the pandemic insight, the success and productiveness of the food manufacturing industry will depend on its commitment to the health and safety of its workers.

Consistently identifying the risks, putting the appropriate controls in place, and using the correct PPE will not only continue to help the workers but will also ensure the success of the industry as a whole.

When it comes time to find the best selection of PPE whatever food manufacturing industry you are in, Liberty Glove and Safety can help. Contact us to learn more about our line of personal protective equipment.