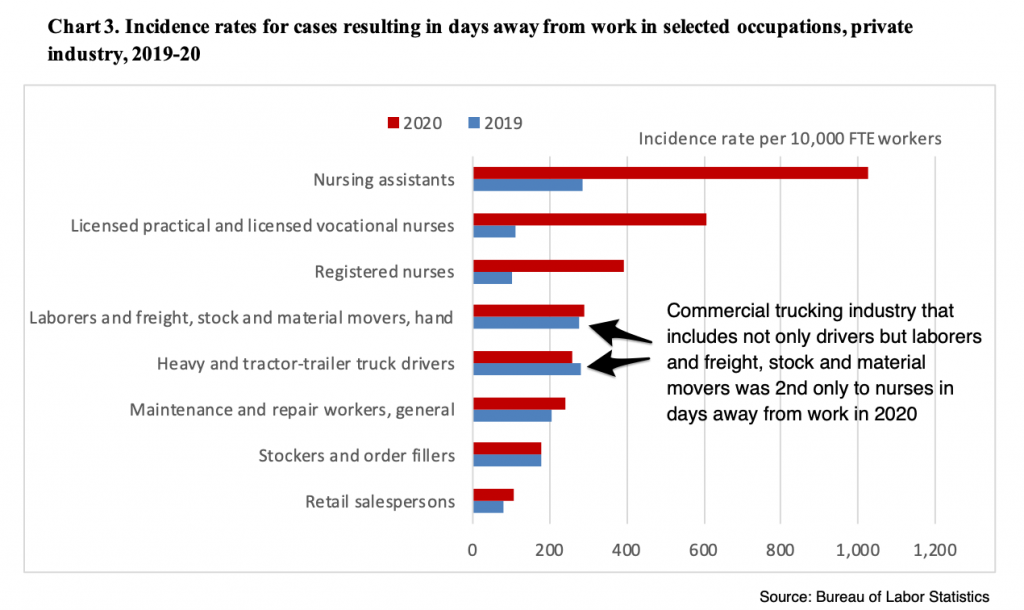

The transportation industry is an essential part of the U.S. economy, and without it, our supply chain would collapse. Yet research indicates that truck drivers were second only to nurses on days away from work due to injury or illness. Identifying the risks and applying safety measures are critical to keeping trucks on the road.

According to American Trucking Association research, 72.5% of the supply chain load goes by truck. And the 2020 Bureau of Labor Statistics economic trends show that commercial trucking employed the most people in the transportation industry.

But this past year, it’s been a challenge to keep the industry moving. Commercial trucking was second only to nursing in a year monopolized by a pandemic for reported days away from work (DAFW) due to injury or illness.

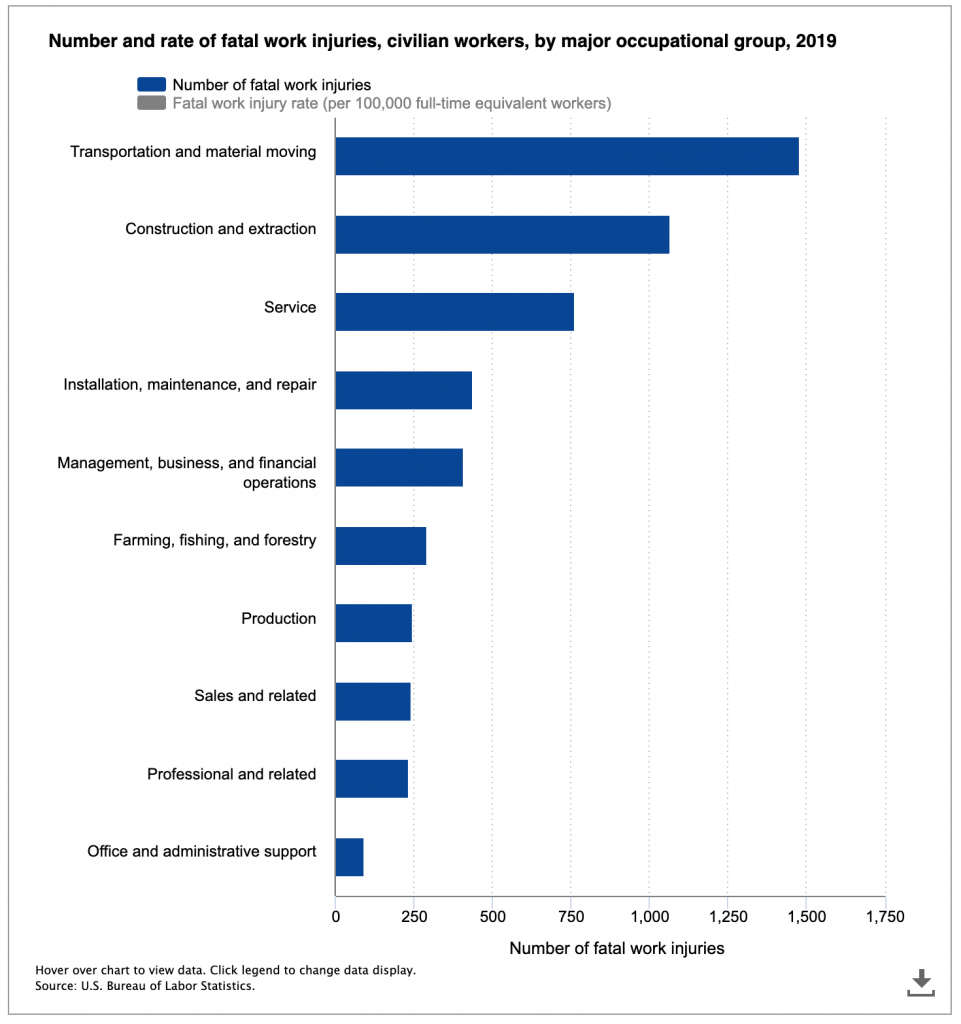

And the Bureau of Labor Statistics (BLS) reports that events involving transportation incidents account for the largest share of workplace fatalities, most of them in long-distance trucking.

OSHA’s 5 Main Trucking Hazards and Suggested Preventions

The Occupational Safety and Health Administration (OSHA) is aware of the statistics and has identified the most commonly reported safety and health hazards along with suggested solutions. We’ve listed them below including some of the most popularly requested PPE.

1. Overexertion/fatigue

Reaction times, awareness, and decision-making abilities fall by as much as 50 percent when someone is sleep-deprived.

Long work hours may also increase the risk of injuries and accidents and contribute to poor health and overall worker fatigue. Support and intervention are essential to combat a demanding work schedule and the fatigue that comes with it.

2. Strains and Sprains

Loading or unloading a truck or lifting heavy boxes, bins, garbage cans, etc., can lead to musculoskeletal disorders (MSD) of the neck, back, and upper extremities.

Many industries have successfully implemented ergonomic interventions that include modifying existing equipment, changing work practices, and purchasing new tools or other devices to assist.

Caption: Along with efficient processes, the DuraWear™ back support belt can offer ergonomic assistance to workers lifting heavy objects.

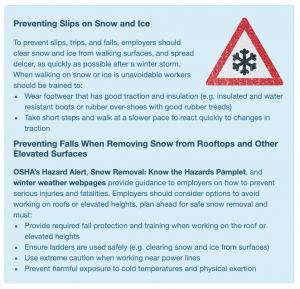

3. Slips, Trips, and Falls

Falling from the cab of a truck, falling on stairs, or into other worksite openings are possible reasons for workplace injury for truckers. Setting in place controls is the first suggested action.

Keep in mind these types of accidents can be significant. Safety boots are an excellent idea to have in the truck cab for workers to use at job sites too.

Caption: The Durawear™ yellow rubber slush boots are perfect for an over the shoe option for your workers. They’re fabric lined with a bar-tread outsole that offers excellent slip resistance.

4. Getting Struck By or Against Objects

Being struck or pushed against objects may happen when a driver opens containers, hitches, or attaches trailers to trucks.

OSHA mandates that employers enforce head protection for workers who may be at risk for head injuries. Hard hats are also often necessary and sometimes required at delivery sites.

Caption: The DuraShell™ cap style hard hat comes in assorted colors with a low profile design and easily adjustable suspension for a comfortable fit. Meets ANSI Z89.1 Standard Type 1, Class C, G, E.

5. Transportation accidents

More than half of fatalities for truck drivers are caused by vehicle-related injuries inside or outside the cab. Proactive employer policy can do much to promote vehicle safety on and off the job.

The OSHA manual stresses the importance of being seen on the job site for just this reason. A hi-vis vest means a worker is less likely to be involved in an accident during the day or night or even inside around people operating moving machinery.

Caption: A HiVizGard™ Class 2 all mesh vest will ensure visibility with its 2” wide silver retro-reflective stripes and bright yellow color. It’s easy to wear with a zipper front closure and plenty of pockets.

Other Frequently Used Protective Equipment in the Trucking Industry:

Work Gloves

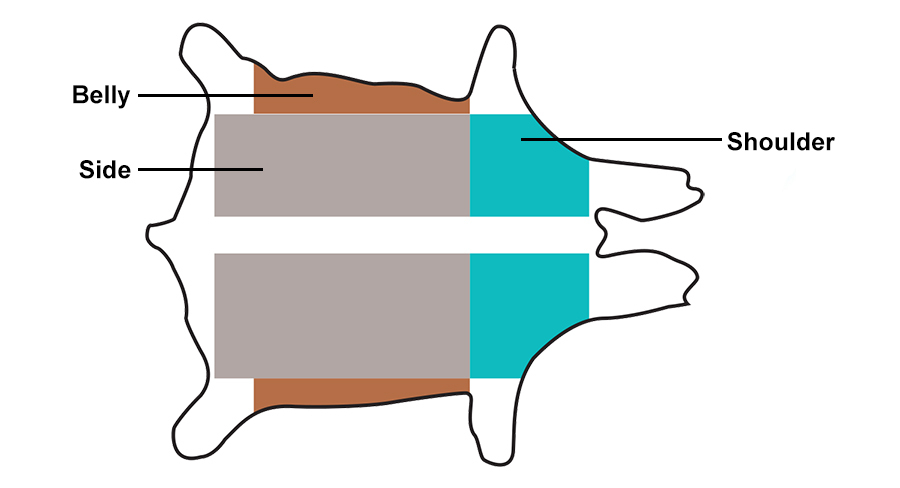

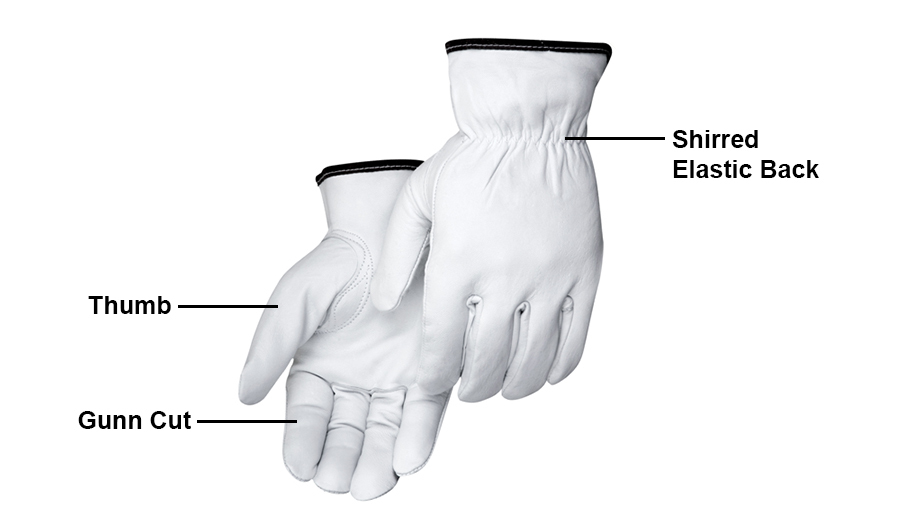

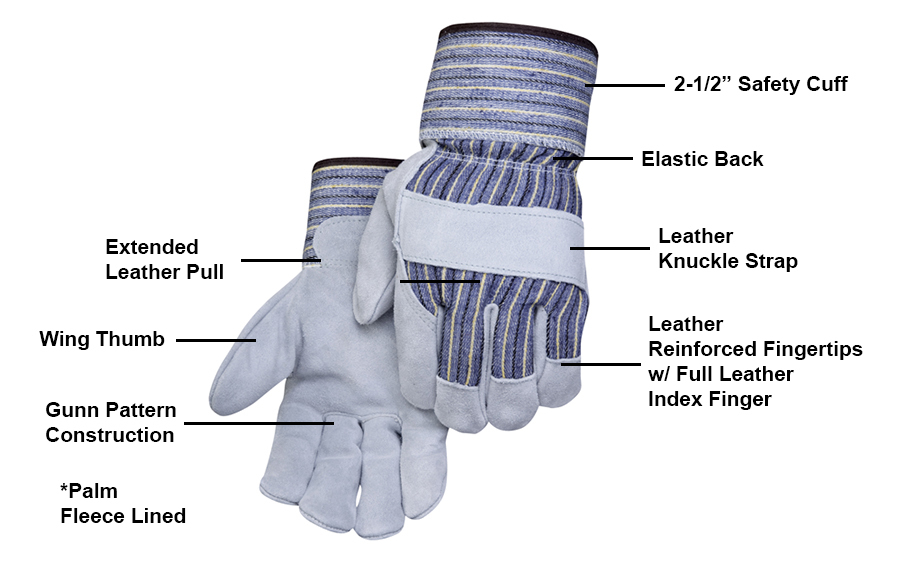

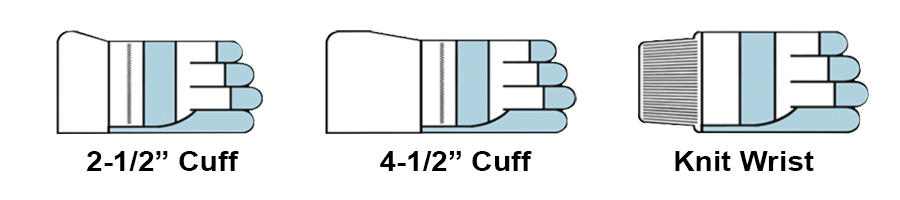

From loading freight to hooking up a trailer, truck drivers need hand protection. Safety gloves that are specially designed for flexible coverage are a good choice.

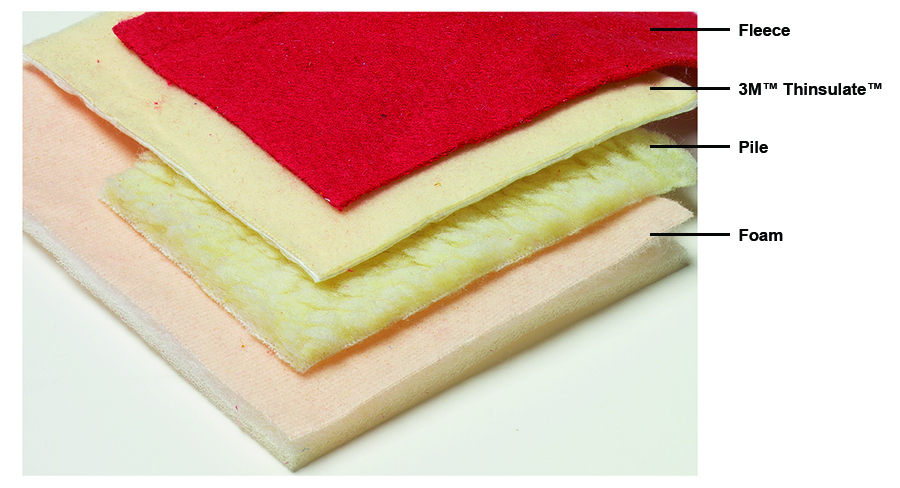

Caption: A pair of Insulated Grain Cowhide Drivers Gloves will protect a worker’s hands in and out of the cab. They are 3M® Thinsulate® lined with a keystone thumb, providing flexibility and giving it an ergonomic design.

Safety Glasses

Protecting a workers’ eyes is something often overlooked, but because the environment at any destination may be unknown, it’s a good idea to be prepared.

Caption: Sporty, semi-frame, and lightweight, the iNOX™ ROADSTER II™ safety glasses meet or exceed the ANSI Z87.1-2015 standard requirements.

Hearing Protection

Another overlooked precaution, hearing protection, is essential when around loud machinery or other tractor-trailers. The disposable styrofoam ones work well and are easy to travel with.

Caption: The DuraPlugs™ disposable foam earplugs are super soft and have easy insertion and removal with a noise reduction rating of 32dB. One size fits all.

Available Information and Resources

Truckers are an integral part of the movement of materials between air, land, and sea. It’s every safety manager’s job to ensure that their drivers stay as safe as possible through it all.

The U.S. Department of Transportation (DOT) provides links to the primary safety sites within the DOT that can help address any health and safety issues in each area.

Air

- Safety. The Federal Aviation Administration (FAA) develops and implements tools and processes to facilitate more effective use of safety data, both inside and outside the agency, to help improve aviation safety.

Land

- Reducing Highway Fatalities. The Federal Highway Administration (FHWA) reports on the national fatality and injury rates every year.

- Driving Safety. National Highway Traffic Safety Administration (NHTSA) provides information on distracted driving, driver education, and occupant protection among other topics.

- Federal Railroad Administration (FRA) makes available railroad safety information, including accidents and incidents, inspections, and highway-rail crossing data.

Sea

- Marine Safety Center works directly with the marine industry in the development of safety standards and policies, response to maritime casualties.

Improving worker safety

Taking a closer look at commercial trucking means addressing the disproportionate number of workplace injuries and fatalities that occur. Keeping those workers safe is a critical component to keeping it running.

Identifying the risks, putting the appropriate strategies in place, and using the recommended PPE will help the workers in the commercial trucking sector and help keep our economy moving forward.

When it comes time to find the best selection of PPE, whatever type of fleet you are in charge of keeping safe, Liberty Glove and Safety can help. Contact us to learn more about our line of personal protective equipment.