The official start of spring is just around the corner. If the warmer weather means you’ll be sending your crew outside, you’ll want to make sure they do it safely. Below we’ve compiled the five most common risks employers should consider before creating a safety plan for their outdoor workers this spring.

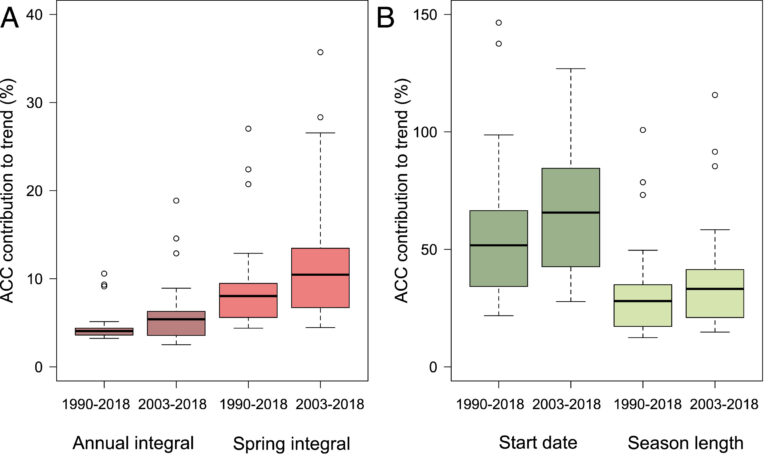

1. Allergies

Springtime brings growth and blossoms to plants and trees, but for outdoor workers who suffer from allergies, that means itchy, watery eyes and dry, irritated throats.

And research published in the Proceedings of the National Academy of Sciences (PNAS) shows that the pollen causing these allergies is only getting worse every spring. It seems that “anthropogenic climate change” (ACC) has exacerbated the season, which now starts 20 days earlier, is ten days longer, and features 21% more pollen than in 1990.

To protect outdoor workers who are triggered by allergens, the American College of Allergy, Asthma, and Immunology recommends first trying to minimize exposure to pollen using protection like face masks or eye protection. For more severe reactions, they suggest over-the-counter or prescription medications.

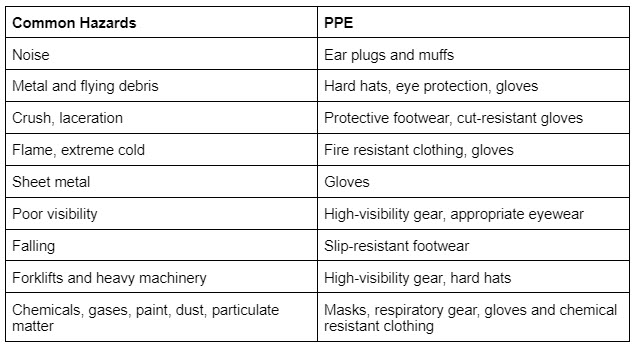

2. Hazardous Chemicals

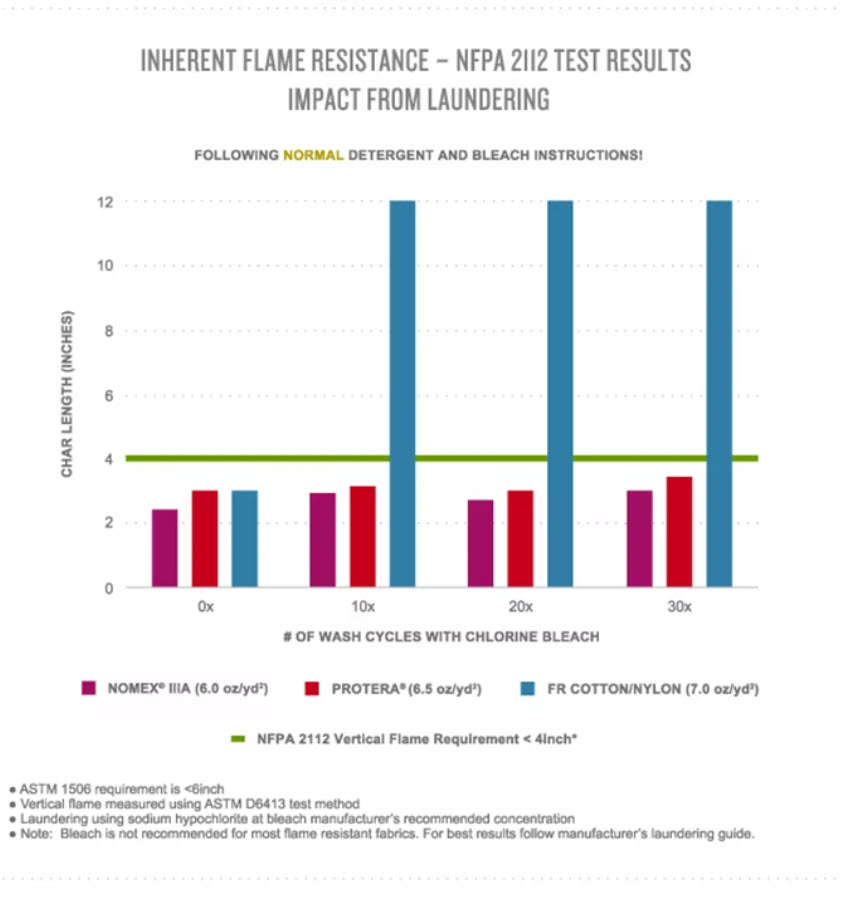

According to the Occupational Safety and Health Administration (OSHA), American workers use tens of thousands of chemicals daily. While many of these chemicals are suspected of being harmful, only a few are regulated in the workplace.

As a result, workers suffer more than 190,000 illnesses and 50,000 deaths annually related to chemical exposures.

Spring cleaning and maintenance often involve many of these hazardous chemicals. OSHA requires workers, especially those working in agriculture, to use skin, hand, and/or respiratory protection when handling these chemicals.

Face masks or respirators can help filter out airborne particles in manufactured chemicals like fertilizers and herbicides. Proper use can reduce the risk of respiratory problems.

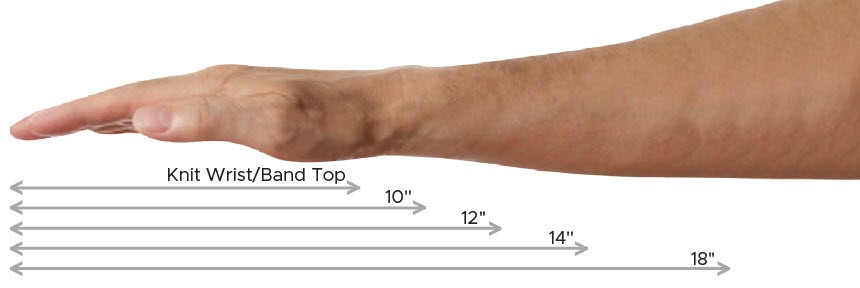

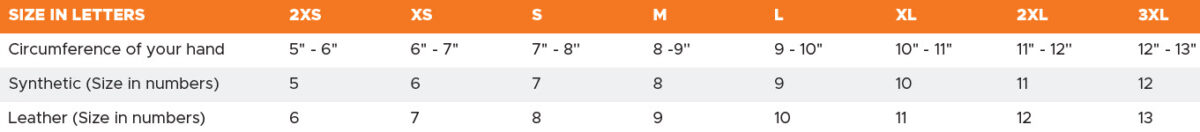

Hands and skin can also be damaged when workers are using chemicals. Wearing the correct type of chemical resistant gloves and protective apparel can help further protect outdoor workers.

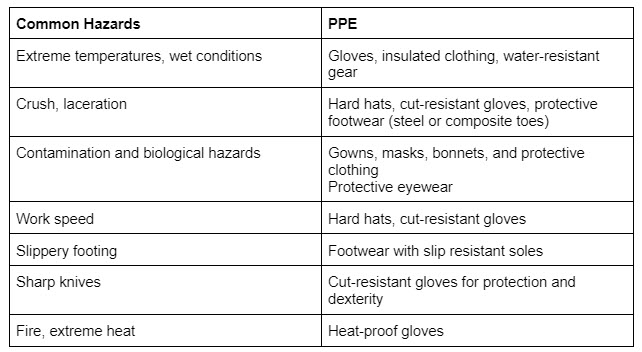

3. Slip and Fall Hazards

Spring showers bring more than just flowers. They also cause mud and wet surfaces, which can cause workers to slip and fall.

And even though springtime temperatures may rise above freezing during the day, they will fall back at night. Ice may accumulate and present yet another early morning slip and fall hazard.

But those aren’t the only spring slip and fall hazards, others include:

- Washed up debris on walkways

- Wet or slick outdoor stairs or handrails

- Overgrown landscaping obstructing walkways or hiding hazards

Wearing appropriate head protection, such as a hard hat or bump cap, can greatly reduce the risk of head injuries in the event of slips and falls.

The shoes workers wear can also play a big part in minimizing the risks. Appropriate footwear, such as waterproof boots with good traction, is critical to prevent accidents.

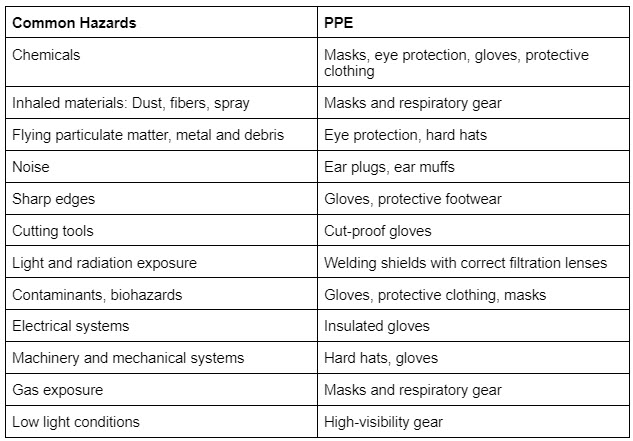

4. Visibility Issues

The spring season is often accompanied by fog and heavy rain, reducing visibility and increasing the risk of accidents. And warmer weather means more people are out and about, increasing the likelihood of incidents due to distracted or reckless drivers.

It’s especially a danger for construction workers who are likely to work in busy traffic areas. Glare and reflections as the sun gets higher in the sky can also make it difficult for drivers to see these workers even in well posted work zones.

To address these visibility issues and help workers see and be seen, workers should have:

- Adequate light sources

- Reflective clothing and equipment

- Proper training

The U.S. Department of Transportation’s Work Zone Safety and Mobility Rule web page provides rule implementation and guidance examples.

5. Unpredictable Weather

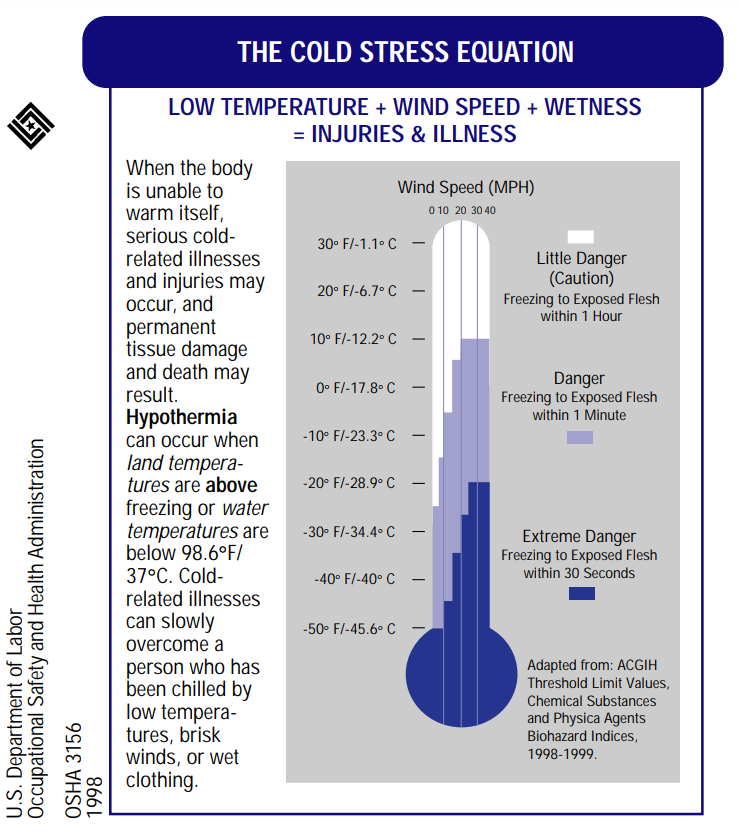

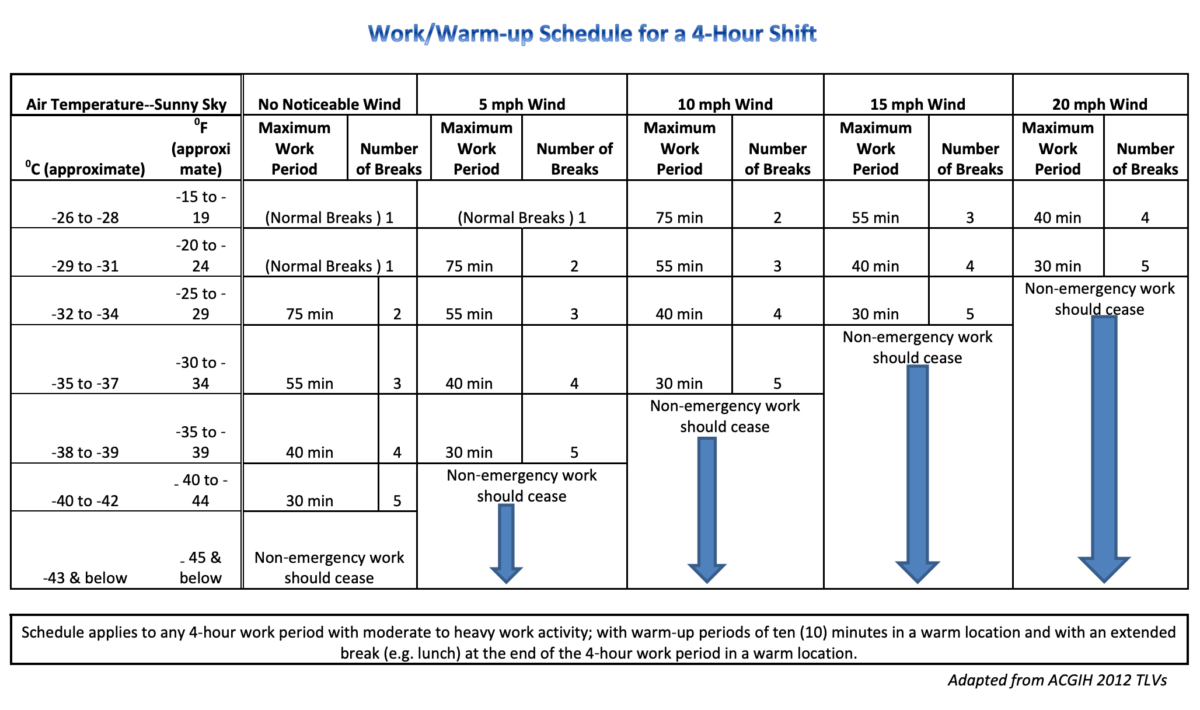

Springtime is a volatile time of year notorious for having wildly unpredictable weather with sudden changes in temperatures.

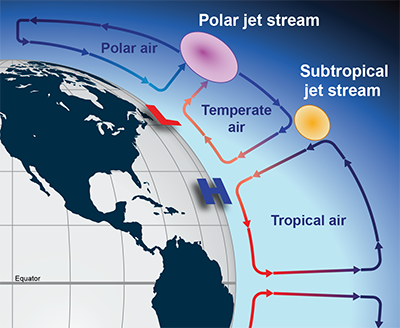

The position and intensity of high and low-pressure systems in spring contribute to those unpredictable weather patterns. The National Weather Service credits most seasonal volatility to jet streams, which are narrow bands of strong wind in the upper levels of the atmosphere.

Their southward dips can bring cold air and stormy weather to some areas, while northward shifts can bring warm, sunny conditions.

While some general patterns can be observed, spring weather can be challenging to predict precisely, making it essential to stay informed and prepared for changing conditions.

Workers should wear appropriate clothing, sticking to a layered approach. They should have outdoor apparel that protects against rain, wind, and those sudden up or down temperatures.

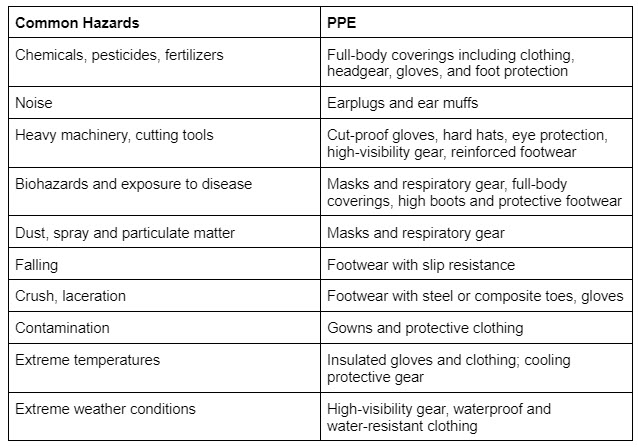

Selecting Spring PPE

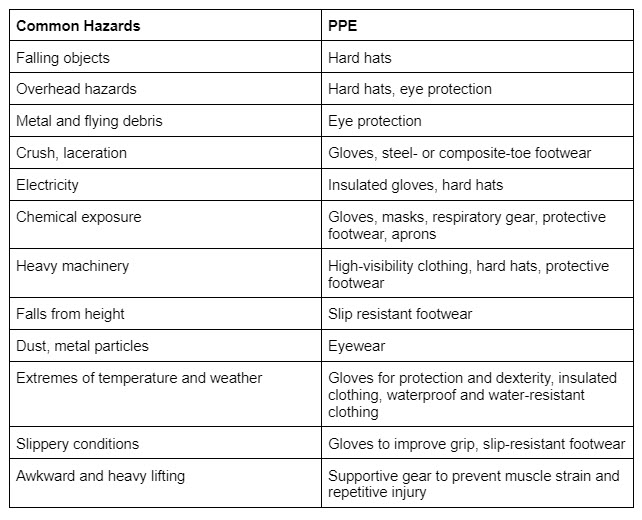

There’s no getting around it, in the springtime, outdoor workers are exposed to a slew of environmental hazards. The risks depend on the type of work, geographic region, and duration of time they are outside.

Assessing the specific hazards associated with an activity is important before determining the appropriate PPE to wear. It is also important to ensure the PPE is properly fitted and in good shape to provide the necessary protection.

OSHA guidelines for selecting PPE say PPE should fit comfortably and that each worker using it should know:

- When it is necessary

- What kind is necessary

- How to properly put it on, adjust, wear and take it off

- The limitations of the equipment

- Proper care and disposal of the equipment

Most PPE manufacturers provide supporting documentation on wearing and using their equipment, which you can reference. You can also check out the free PPE training resources that are online for more information.

Spring Into Safety

Even though outdoor work will always involve an element of risk, no matter what season it is, there are ways employers can help minimize it. This includes risk assessment, proper safety controls, and wearing appropriate personal protective equipment.

As we move between winter and summer, it’s critical to be aware of the hazards associated with the season and take suitable safety measures to protect your outdoor workers. Liberty Safety can help. Contact us to learn more about our personal protective equipment for this season and throughout the year.