Seafood is more popular than ever, which means the industry is busier than ever too. Unfortunately, it’s the kind of demand often associated with increased occupational health and safety problems.

Last year’s U.S. Bureau of Labor Statistics (BLS) incidence rates table showed that injuries and illnesses among maritime workers were higher than in most other industries.

It’s worrisome data that demands attention. This post further explores the hazards and work conditions often responsible for those higher injury and illness rates. We also take a deep dive into the controls and popular protections currently in use, including PPE.

Common Maritime Industry Worker Risks

The Center for Maritime Safety and Health Studies (CMSHS) considers maritime workers as people employed on vessels, at waterfront facilities working in and around vessels, and onshore directly supporting the seafood industry.

No matter where a maritime worker is stationed, it’s essential the hazards are identified in order to be able to suggest effective controls.

The Occupational Safety and Health Administration (OSHA) and the Centers for Disease Control and Prevention (CDC) track the industry. And though each environment presents its own set of unique challenges, they share the following risks:

1. Physical Accidents

These are accidents that are associated with the worksite. Maritime workers are susceptible to these types of injuries because common environmental and worksite risks, including heat and cold stress, vibration, noise, and ergonomics hazards, cause them. Injuries due to mechanical and electrical equipment are also a high risk.

2. Bacterial and Parasitic Infections

Some organic substances that may cause health problems are often present in many seafood workers’ responsibilities. For example, the water spraying process, which is a standard application in seafood processing, may form aerosols with bacteria that can be inhaled. Additionally, parasites present when processing fish are also a threat.

3. Chemical and Toxin Exposure

Seafood processing may, at times, require the use of dangerous chemical substances. Dermatologics, carcinogens, and asthmatic agents are some of the toxins present in the chemicals used when processing seafood. Products used for sanitizing and cooling foods are examples of products that pose a significant risk.

4. Stress Related Risks

Stress hazards are those that affect the psychological well-being of workers. They are associated with and relate to how the work is designed, organized, and managed, as well as the job’s safety, economic and social contexts. Long hours and even days away from home, along with constant physical threats, can contribute to poor mental health.

Health Problems from Known Hazards

The National Institute for Occupational Safety and Health (NIOSH) Center for Maritime Safety and Health Studies (CMSHS) estimates approximately 400,000 workers are employed in U.S. maritime industries.

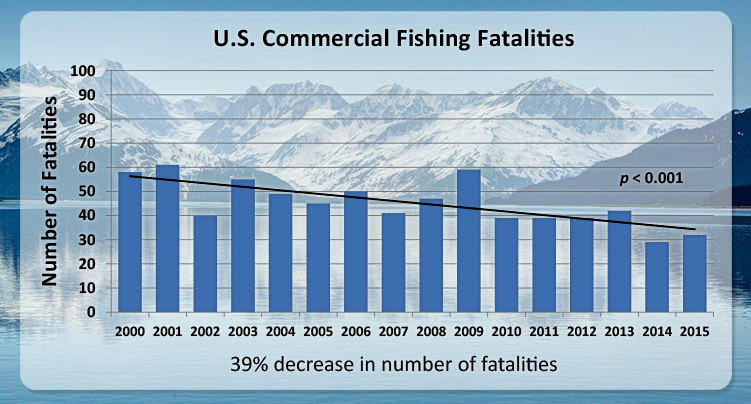

They note that these workers face a high risk of fatality, injury, and illness and regard commercial fishing as one of the most dangerous jobs in the U.S., second only to mining.

Hazards presented by the maritime environment can be encountered both on the water and at waterfront facilities. Last year, the CMSHS estimated 61,600 nonfatal injuries/illnesses (5,370 per 100,000) occurred, nearly twice the rate for all U.S. workers and one of the highest injury/illness rates among maritime workers.

The list of potential injuries or illnesses is extensive and often includes the following:

| INJURY OR ILLNESS | MAJOR CAUSE |

| Sprains and fractures | Slippery floors |

| Cuts and scrapes |

Knives and tools |

| Abdominal issue |

Infectious bacteria or pathogens |

| Asthma, lung infections, pneumonitis |

Continuous wet environments |

| Burn injuries (especially on the hands) |

Preparing and smoking fish |

| Dislocation or broken bones and/or internal injuries | Motor vehicles or large equipment |

Controls Used to Protect Workers

The CMSHS provides resources to create and implement the appropriate controls needed to protect maritime workers.

They contribute to the following NIOSH Strategic Plan for FYs 2019-2024 goals that aim to help reduce injuries and illness among maritime workers:

| INJURY OR ILLNESS | MAJOR CAUSE |

| Sprains and fractures | Slippery floors |

| Cuts and scrapes |

Knives and tools |

| Abdominal issue |

Infectious bacteria or pathogens |

| Asthma, lung infections, pneumonitis |

Continuous wet environments |

| Burn injuries (especially on the hands) |

Preparing and smoking fish |

| Dislocation or broken bones and/or internal injuries | Motor vehicles or large equipment |

Controls Used to Protect Workers

The CMSHS provides resources to create and implement the appropriate controls needed to protect maritime workers.

They contribute to the following NIOSH Strategic Plan for FYs 2019-2024 goals that aim to help reduce injuries and illness among maritime workers:

PPE that Promotes Maritime Worker Safety

A risk analysis study found that marine safety campaigns focusing on PPE for workers can be the most effective at reducing risks and subsequent injuries.

The results of the study stated:

- The most influential risk factors were age, risk awareness, sea experience, and PPE availability.

- 4% of marine workers reported needing proper PPE training.

- The injury rate among respondents untrained in PPE was as much as 33% higher than others.

- Overall, PPE availability had the most significant potential to decrease the probability of injuries.

Overall, the study concluded that PPE availability is the most significant factor in promoting marine safety.

Some of the protections that may be necessary to keep workers safe and protect them from the long-term effects of maritime work include:

Protective Clothing

Food processing may, at times, require the use of dangerous biological or chemical substances that could harm those workers who are regularly exposed to them. Handling seafood is definitely considered a biological hazard, and sanitizing and cooling seafood also poses a significant chemical threat.

Coveralls and aprons are some of the protections necessary to keep workers safe and protect them from the long-term effects of these types of chemical or biological exposures.

Made from a 6-mil thick vinyl, which is a widely used material in the PPE industry, the DuraWear™ Blue Vinyl Apron is easily cleaned and maintained. It is an excellent choice for the seafood processing industry because it’s resistant to oils, chemicals, fats, grease and salt and provides good protection against splatters and saturation.

- Adjustable neck and back strap

- Size 35” x 45”

- Complies with Federal regulation for food contact

- Also available in white (1338W)

Hearing Protection

Hearing protection is required in work environments that are exposed to noise levels equal to or greater than 85 decibels (dB) averaged over an eight-hour period. Most manufacturing facilities fit into this category.

OSHA notes that noise may be a problem in your facility if workers report:

- Hearing ringing or humming in their ears when they leave work

- Have to shout to be heard by a coworker an arm’s length away

- Experience temporary hearing loss when leaving work

The best hearing protection is the one that is comfortable and convenient and one that workers will wear every time they are in an environment with hazardous noise.

DuraPlugsTM Corded Earplugs have a slow-recovery tapered shape foam for easy insertion and removal. They are low-pressure, self-adjusting foam which offers long-wearing comfort. The cords mean they are less likely to be separated and fall into food.

Metal Detectable Earplugs help prevent contamination of products in case an earplug accidentally gets into food production because they can be quickly identified with magnets. They consist of two earplugs that have a tapered bullet shape foam for easy insertion and removal.

Both models offer a Noise Reduction Rating (NRR): 32 dB

Respiratory Protection

Many jobs in the maritime industry involve working around hazardous particles. Painting, welding, and sandblasting are common examples of hazards in the maritime industry. Nuisance masks may be appropriate for dust and airborne particulates.

Cartridge masks are recommended when particle exposure is at higher concentrations or exposure to more dangerous substances.

Air contaminants are commonly classified as particulates or gas and vapor contaminants. Compliance with the OSHA Respiratory Protection Standard could avert harm to maritime workers exposed to them.

The DuraMask™ Nuisance Mask uses a fabric-wrapped elastic headband and an adjustable aluminum nose piece to provide more user comfort. It’s best used in environments with minimal fluid exposure as a physical barrier between the wearer and potential non-hazardous contaminants like sawdust or dirt.

- Fabric-wrapped elastic band

- Adjustable aluminum nose piece

- Single strap

- Non-toxic applications

Hand Protection

Hand injuries due to exposure to harsh chemicals are common types of accidents among maritime industry workers. It’s why gloves that offer chemical resistance and food safety are necessary for the industry.

For the majority of maritime workers, a chemical resistant latex glove offers the right level of safety. But only if it’s a glove that is comfortable to wear and can handle a wide variety of jobs.

These Blue Latex Canners are safe for food handling and offer a comfortable fit for sizes XS to XL. Unsupported gloves are typically designed from latex, nitrile, and vinyl and feature no lining underneath. Ceramic formers with embossed grip patterns are dipped directly into protective polymers.

Generally, unsupported gloves are available in palm thicknesses that range from 11 to 30 mil. These gloves are used primarily for disposable applications, such as food preparation, painting, household cleaning, and animal husbandry.

- 18 mil

- Embossed Grip on palm and fingers

- 12” Length

- Unlined

Foot Protection

OSHA requirements state that workers must wear protective footwear when working in areas where there is a danger of falling or rolling objects or objects piercing the sole. Protective footwear also must meet ANSI Z41 or equivalent design requirements. Look for:

Bulky cargo and machinery, welding, falling objects, and slick surfaces often found in maritime environments create conditions where appropriate footwear is required. Safety boots help workers to find their footing and help prevent slips and falls. Protective footwear also protects feet from crushing injuries. Look for rubber or PVC boots that are both non-skid and steel-toed.

The DuraWear™ Steel Toe PVC Boots have a durable build with steel toe protection. Constructed of a flexible yet sturdy PVC, it’s a slip-on boot that’s 100% waterproof and resistant to a broad range of contaminants.

- One-piece injection mold

- Black high molecular PVC compound

- Bar cleat outsole with an over-the-sock style

- Availability in plain or steel toe

Continuing to Keep Maritime Workers Safe

Even with all the resources available, the success and productiveness of the maritime industry will depend on its commitment to the health and safety of its workers.

Consistently identifying the risks, putting the appropriate controls in place, and using the correct PPE will continue to help the workers and ensure the industry’s success as a whole.

When it comes time to find the best selection of PPE for maritime work environments, Liberty Safety can help. Contact us to learn more about our line of personal protective equipment.