Keeping workers healthy and safe is the most obvious goal of any employer’s safety program. The benefits of a safe and healthy workforce, driven by regular use of the appropriate PPE, extend to your business as well.

We’ll take a look at some of these business benefits as well as how PPE helps workers stay safe across a range of industries.

Appropriate Use of PPE Brings Benefits to Your Business

Your business is known by the practices you maintain, and how you handle safety practices affects your reputation and your ability to attract the type of workers you want.

By creating a safe work environment, you can:

- Show your values. Through safety measures, you can demonstrate concretely that you care about the people who work for you.

- Set an example. Show that safety is important by having managers and visitors maintain and observe consistent safety practices that include PPE.

- Relieve worker stress. With adequate protection, people can concentrate better on the job at hand, without the distraction and concern for their own welfare or risk of injury.

- Retain employees. In a safe environment, job satisfaction is higher. With higher satisfaction, you experience less turnover.

- Keep absenteeism down, spirits up. Downtime is lower and morale higher when there are fewer accidents.

- Demonstrate professionalism. Requiring the use of appropriate PPE puts an emphasis on doing things right.

- Keep your organization in good standing. Compliance with required regulations helps you avoid fines and fees and correct, consistent use of PPE also protects workers and the company from a variety of issues should an injury occur.

- Increase effectiveness. Using the right PPE often helps people work more effectively – providing better grip, more secure footing, and protection from extreme conditions both indoors and outdoors.

By definition, hazards are the sources of potential injury or damage; risks represent the likelihood of injury from a particular hazard. PPE is designed to prevent injury from specific events and from long-term exposure to hazardous conditions.

Regardless of the industry, multiple hazard categories are often present. PPE offers specialized protection for the eyes, ears, respiratory system, skin, head, hands, limbs, and body as determined by the industry and predominant types of hazards.

Let’s take a closer look at some of the potential hazards associated with various industries and how PPE helps guard the health and well-being of workers.

General Hazards

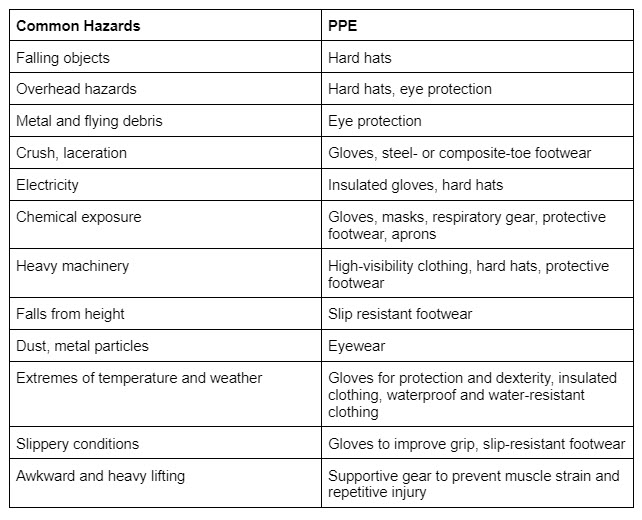

Every industry has its inherent hazards. While many hazards can be mitigated through the design and engineering of systems and practices to protect workers, others remain. OSHA describes an array of hazards that can be present in any workplace. The following list gives an overview of some common hazard categories with selected examples:

- General Industrial Safety: Unsafe working conditions, confined spaces, hazards for slips, trips and falls (on same level)

- Biological: Mold, insects, infectious diseases, bird or animal droppings

- Physical or environmental: Noise, temperature extremes, weather conditions, radiation

- Ergonomic: Repetitive motion, awkward and heavy lifting, musculoskeletal over-extension

- Chemical: Solid, liquid or gaseous chemicals and dust, particles, dust, toxins that enter the respiratory system or irritate the skin

- Organizational: Sources of stress including workload demands, violence, and harassment

Along with proper training in safe work practices, correctly used PPE serves as the last line of defense to protect workers from fatal, catastrophic, and other injuries.

Typical Industry Hazards and Relevant PPE

Every industry has its own set of specific standards and safety precautions to be followed. PPE requirements may overlap or be tailored to particular applications. In all industries, falls, slips, and trips are among the most common hazards.

OSHA offers recommended practices to help employers identify hazards specific to their workplace and industry. Across the board, appropriate PPE and hazard communication are vital to maintaining the safety of the workforce.

Several key industry sectors rely heavily on PPE to reduce injuries and improve worker safety in the workplace. We’ll take a look at some of the common hazards in the following industries: manufacturing; food processing and restaurant; maintenance, repair, and operations (MRO); farming and agriculture; and construction. Liberty Safety provides a wide range of PPE to help workers in many industries stay safe and do their jobs efficiently.

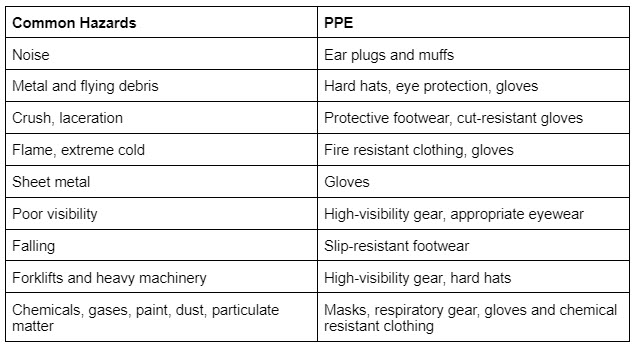

Manufacturing

Manufacturing encompasses a range of processes that requires protection of virtually every type, from extreme physical and environmental conditions to chemical hazards and a wide range of general hazards. Workers in industrial production roles face hazards associated with machinery, mechanical processes, material handling, repetitive stress, fire and electrical hazards among others.

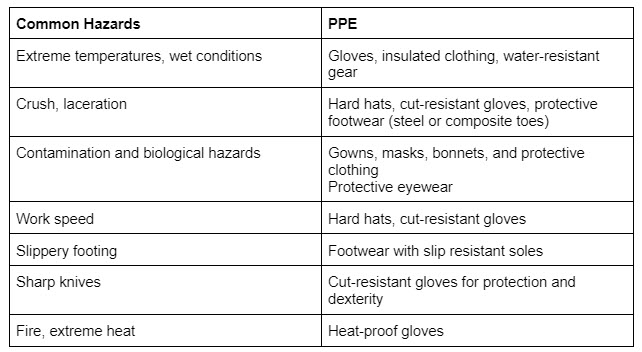

Food Processing and Restaurant

The food processing industry covers a wide variety of activities, from butchering and meat processing to canneries, bakeries, fisheries, packing plants, dairies, rendering and more. Workers in each category face industry specific hazards.

Restaurant kitchens are high heat, high pressure environments where workers are dealing with sharp tools and the potential for slippery surfaces underfoot while working at a fast pace. The Economics Daily notes that workplace hazards and likelihood of injury depend on the type of food service operation and its activities.

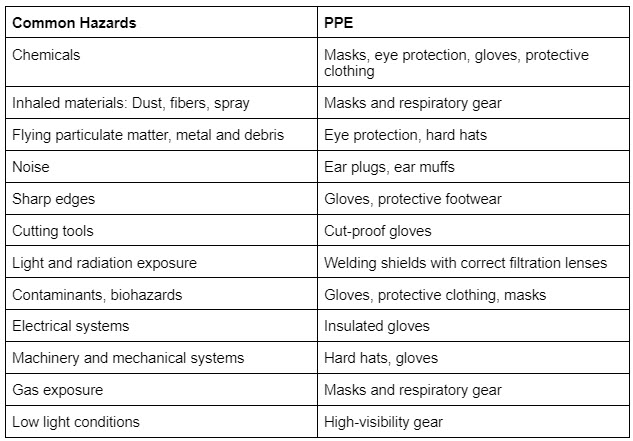

Maintenance, Repair and Operations (MRO)

These activities support every industry, maintaining the means of production and the physical facilities. HVAC workers, plumbers, welders, pipefitters, machinists, and vehicle maintenance crew are just some of the workers who keep operations running and need a wide range of protective gear.

Detailed safety recommendations and specifications are provided by individual trade associations such as the American Welding Society fact sheets and guidelines and the National Fire Protection Association codes and standards for workplace safety when working around electrical hazards.

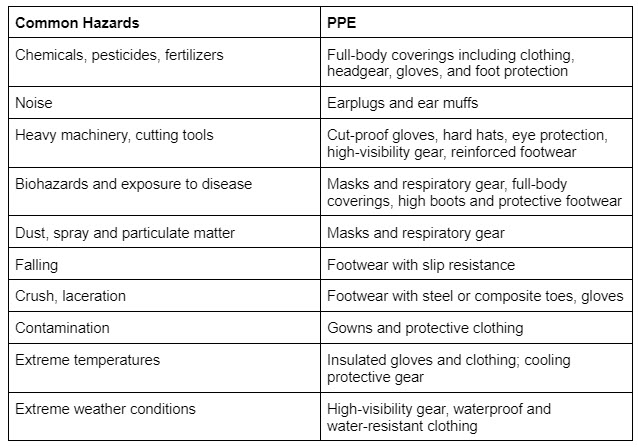

Farming and Agriculture

The processes involved in producing crops and raising livestock require attention to the health and safety of the workers and the health of the crops and animals under their care. As an industry, agriculture ranks among the highest in the number of injuries reported annually, according to the National Institute for Occupational Safety and Health. In 2020 alone 11,880 injuries related to agricultural production and requiring days off work were reported.

Sanitation involves exposure to toxic chemicals, and farm production work involves exposure to fertilizers, pesticides, and other chemicals which may be in solid, liquid or spray form. Machinery, saws, tractors, and farm equipment present a wide range of hazards.

Construction

In the construction industry, falls account for more than one-third of all construction work-related deaths. According to The Economics Daily, published by the U. S. Bureau of Labor Statistics, 32% of nonfatal injuries from falls, slips, and trips in the construction industry in 2019 required days away from work. Adding to the significance for both workers and employers, for these cases the median time away from work was 28 days.

Beyond the safety harnesses and other devices that prevent falls, construction workers need the protection of a wide range of gear. Falls to a lower level, overexertion related to handling objects, being struck by objects, and falls on the same level are the top four causes of injury in the construction industry, according to data from Liberty Mutual Insurance.

Attributes of Appropriate PPE

Gear Needs to be Comfortable

Must be sized correctly to fit the worker. Eyewear must fit the face correctly, clothing must fit properly. Oversized clothing becomes a hazard because it could become caught in equipment.

Only works when it’s used. If it doesn’t fit correctly and comfortably, it will be avoided–making the worker vulnerable to injury or exposure that could be life threatening.

Gear Needs to be Suited to the Task

Base choice on the situation. What’s ideal in one situation may be entirely wrong in another. Choose the right boots for crush protection or to add increased slip resistance on oily or greasy surfaces. Gloves must be chosen correctly–to provide cut-resistance or to give an improved grip–with the right fit for dexterity. Sometimes disposable gowns and gloves are needed, other situations demand durable clothing designed for repeated heavy use.

Gear Must Perform

Check the standards. As appropriate, PPE must meet the standards to prevent penetration by hazardous materials, toxins, and chemicals.

Choose tested products that have satisfactory performance under real-world conditions.

Do the Job Well, and Safely

PPE both provides protection from hazards and helps workers do their jobs more effectively. The right gear can offer improved grip, better footing, support for lifting and movement, visibility, and temperature regulation.

But to be useful, it has to be worn–and that means workers need to have gear that fits correctly and comfortably, as well as being designed with appropriate levels of protection.

Choosing the correct gear and attaining the best fit can be a challenge. Liberty Safety understands all that goes into that decision and offers a wide range of choices for fit, style, and performance. We can help you select gear that fits your workforce as well as the job at hand.