Glove size and style are only a couple of the choices to consider before buying safety gloves for you and your team. Knowing what goes into the design of each pair is also important in making a better selection.

Below we look at the worksite risks to your hands and break down the parts of a glove selection chart that address them, including:

- Glove Construction

- Wrist Styles

- Glove Fit (size and length)

- Coating Materials

- Lining Materials

Each section will give you a clear explanation of its key features and the applications where it is typically used.

Identifying Worksite Hand Hazards

“It is essential that employees use gloves specifically designed for the hazards and tasks found in their workplace because gloves designed for one function may not protect against a different function, even though they may appear to be an appropriate protective device.” – Occupational Safety and Health Administration (OSHA)

Make it easy on yourself and narrow the risks down to three main areas:

- Personal: Hazards caused by something you might be wearing are considered a personal risk. This could be a watch, ring, clothing, or even ill-fitting safety gloves.

- Mechanical: A mechanical risk involves some type of moving parts where hands or fingers could be pinched, cut, severed, etc. It could also be a situation where objects could fall and crush the hands or cause other such damage.

- Contact: Anything your hands come in contact with, including chemicals, high temperatures, and sharp edges, puts them at risk for injury. Because it involves a multitude of objects and situations, contact hazards cause most workplace mishaps.

OSHA provides worksite assessment guidance that will help you organize and analyze the information so you can determine the gloves that will be most appropriate.

Safety Glove Selection Guide

Hand injuries and their impact on employees can be minimized by following recommended safe processes and wearing proper safety gloves.

Luckily, choosing the right safety gloves is easier than ever. A wide variety of features are available so that any workplace risk is covered.

The following is a guide to what you need to know about the makeup of protective work gloves and the hazards they can guard against.

Looking at Glove Construction

The construction of safety gloves starts with selecting a pattern style. The pattern used depends on preference and often the intended application.

|

CLUTE CUT An economical way to protect the hand without a bulky seam. Usually a cut and sewn product. |

GUNN CUT Reinforced material between the index, middle and ring finger, where abrasion often reduces the life of the glove prematurely. |

REVERSIBLE Ambidextrous gloves allow for longer wear since it can be worn on either hand. |

|

CLUTE CUT An economical way to protect the hand without a bulky seam. Usually a cut and sewn product. |

GUNN CUT Reinforced material between the index, middle and ring finger, where abrasion often reduces the life of the glove prematurely. |

REVERSIBLE Ambidextrous gloves allow for longer wear since it can be worn on either hand. |

Wrist Styles

The various types of wrists and cuffs fit specific purposes and give functionality and further protection for worker safety needs.

SLIP-ON

Easy donning and doffing are the qualities of this style. One piece construction, no seams to erode.

BAND TOP

Short extension cuff offers comfort and additional wrist protection.

GAUNTLET

Provides added protection for the lower forearm. The design allows maximum movement of the forearm.

KNIT WRIST

Designed to hold the glove firmly on the hand and prevent debris from entering the glove through the wrist area.

SAFETY CUFF

In addition to the protection of the gauntlet cuff, the safety cuff offers more protection in the wrist area. Safety cuff gloves slide on and off easily as well as release from the hand in a quick motion.

Finding the Right Glove Fit

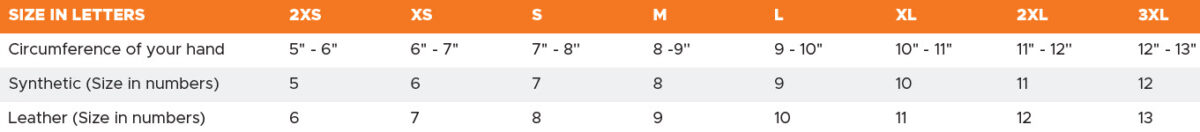

Measuring Glove Size

The chart below illustrates a quick way to determine the user’s glove size when selecting hand protection. While not exact, it will give an approximate size range for the individual. (Measure the circumference of your hand in inches between your thumb and knuckle.)

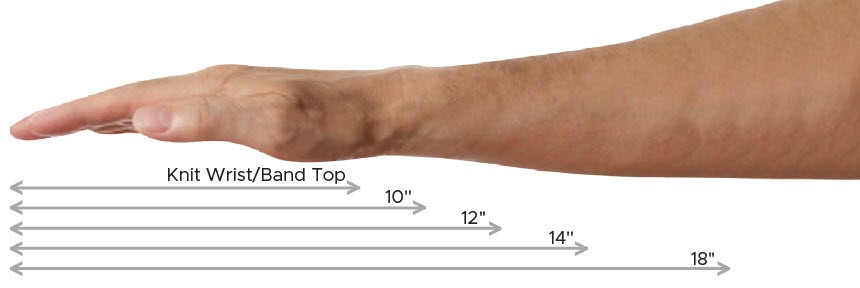

Measuring Glove Length

Having the proper glove length is imperative for proper hand/arm protection. The illustration below depicts the way to identify the length of the glove the specific user needs.

Selecting the Correct Coating Materials

COATING: NITRILE, FOAM NITRILE AND SANDY/MICRO FOAM NITRILE

DESCRIPTION

Nitrile coated seamless gloves are a prevalent choice because they are durable and ideal for general-purpose work. As a material, Nitrile stands up well against tears and abrasions and withstands significant temperature differences. Foam Nitrile coated seamless gloves are best used in wet or oily conditions because the coating works like a sponge and keeps the surface dry. This makes gripping with the gloves on a lot easier. Sandy Nitrile is known for its abrasion and higher resistance. It offers a tighter fit than other nitrile coatings. It works well in wet and oily environments. Micro Foam Nitrile have a somewhat tacky finish and offer good breathability and flexibility.

APPLICATION

■ Parts Assembly

■ Material Assembly

■ Equipment Maintenance

■ Parts Cleaning

COATING: LATEX AND SANDY LATEX

DESCRIPTION

Latex coated gloves offer a fantastic grip and are often preferred over Nitrile when gripping in both wet and dry conditions is essential. Sandy latex provides a superior grip in wet or dry applications because of its grit. Outside workers appreciate how easy these gloves make grabbing bricks or hauling other building materials.

APPLICATION

■ Construction

■ Demolition

■ Masonry and Tile

■ Material Handling

COATING: POLYURETHANE

DESCRIPTION

Polyurethane, commonly called PU, is used to increase puncture protection with only a thin coating. Though less durable than other coated seamless gloves, they offer a greater dexterity and grip because of the thinness of the PU coats. In addition, you can count on PU to enhance the grip without being sticky, too, while providing good resistance to oils and some chemicals.

APPLICATION

■ Material Assembly

■ Quality Control

■ Inspection

■ General Assembly

COATING: PVC (POLYVINYL CHLORIDE)

DESCRIPTION

PVC coated seamless gloves work well with adhesives and resist abrasions. Most adhesives do not stick to a glove’s surface with PVC, so they’re often used in an application where applying a sealant is necessary. In addition, PVC performs well in the cold and has a certain amount of abrasion resistance.

APPLICATION

■ Construction

■ Mining

■ Petrochemicals

■ Handling Oily Materials

COATING: NEOPRENE

DESCRIPTION

Neoprene is a synthetic rubber that has good chemical stability and good heat-resistant properties. Therefore, it resists oil and has exceptional dry, wet, and oily grip but has low abrasion resistance. As a result, it is often used for chemical-resistant and self-extinguishing applications.

APPLICATION

■ Handling Oily Materials

■ Maintenance

■ Fishing

■ Machine Operations

Considering Glove Liner Materials

LINER: NYLON

DESCRIPTION

A low lint synthetic fiber which provides high tensile strength that excels in applications such as inspection and parts assembly. Nylon gloves will help protect product from finger prints and contamination.

APPLICATION

■ Paint Work

■ Pharmaceuticals

■ Inspection

■ Parts Assembly

LINER: KEVLAR®

DESCRIPTION

Kevlar® is one of the strongest man-made fibers available with excellent cut protection and heat insulation. It is designed to protect hands from the sharp edges of metals, ceramics, glass and other materials. Pound for pound it is five times stronger than stainless steel.

APPLICATION

■ Paper Industry

■ Shipping and Receiving

■ Metal Working

■ Light Duty Assembly

■ General Assembly

■ Operations/Maintenance

LINER: HPPE (HIGH PERFORMANCE POLYETHYLENE)

DESCRIPTION

High performance polyethylene fibers that are specially designed to protect against cuts and abrasions when handling sharp and abrasive objects. These fibers can be engineered in a variety of composite-knit yarns, some featuring high-strength composite fiber blends for higher cut resistance and dexterity.

APPLICATION

■ Metal Working

■ Warehouse

■ General Maintenance

LINER: LEATHER/SYNTHETIC LEATHER

DESCRIPTION

Leather is traditionally used to provide excellent and sturdy protection against cuts and abrasions. Breathability will vary based on the leather types but overall are very durable and comfortable to wear. Leather gloves are an excellent choice for handling sharp objects. Synthethic Leather is a man-made fabric that simulates genuine leather. It is used for basic protection against abrasion and offers good insulation depending on construction. Often used as a substitute for real leather, synthetic leather is light weight, easy to clean, durable and stain resistant.

APPLICATION

■ Construction

■ Foundry

■ Warehouse

■ Shipping and Receiving

■ Agricultural

■ Industrial

■ Cabling

LINER: COTTON

DESCRIPTION

An excellent choice for protection against abrasion. It is lightweight and breathable for light-duty applications. Also offers good insulation depending on construction which can be washed and bleached. Cotton lisle is a very light weight cotton glove that is ambidextrous and can be used as a liner for light duty applications only.

APPLICATION

■ Assembly

■ Inspection

■ Parts Handling

■ Light Warehouse Applications

■ Automotive

■ Food Industry

LINER: ACRYLIC

DESCRIPTION

Acrylic is a lightweight, soft, wool-like appearance that is known to provide excellent insulation. It is resilient while resistant to shrinkage and wrinkles.

APPLICATION

■ Cold Weather Environments

■ Refrigeration

Making the Best Choice for Your Hands

Though safety gloves aren’t considered the first line of defense, industry experts still recommend them as a highly effective way to prevent hand injuries. Research shows that 70.9% of hand injuries can be prevented with proper safety gloves.

With touchscreen capabilities, comfort designs, weather protection, and great fits, there is a choice for every job and every industry.

Liberty Safety offers a large selection of gloves for most industries. We can help you decipher all the available options and clear up any questions.

Contact us today to request a sample for your industry.