Workplace safety stands as a concern for organizations across all industries. Recognizing the need for personal protective equipment (PPE), Liberty Safety has emerged as a trusted provider of top-quality safety solutions.

June is National Safety Month, a nationwide initiative dedicated to promoting workplace safety approaches. It’s the perfect time to make sure your employees know just how much their safety matters to you and your business. Liberty Safety shares your commitment to safeguarding employees and is a proud member of the National Safety Council (NSC).

In this blog post, let’s explore the significance of National Safety Month and shed light on these core values your organization shares with Liberty Safety.

National Safety Month: A Time to Prioritize Workplace Safety

National Safety Month serves as a catalyst for organizations to prioritize the well-being of their employees and create a culture of safety.

This month-long initiative, created by the National Safety Council (NSC) in 1996, aims to raise awareness about workplace safety, reduce incidents, and foster a proactive approach to occupational health and well-being.

By actively participating in National Safety Month, organizations demonstrate their commitment to protecting their workforce and cultivating a safe working environment.

Liberty Safety fully supports the goals of National Safety Month through their dedication to providing top-quality PPE products.

Join us in exploring the weekly topics for 2023 Weekly Topics, per the NSC.org

Week 1: Emergency Preparedness

National Safety Month starts with a critical topic: Emergency Preparedness. Every year, emergencies such as natural disasters, fires, and workplace incidents claim lives and cause injuries. Understanding how to respond can make a significant difference.

A well-developed emergency plan and a basic emergency supply kit is vital for both households and workplaces. Training is another crucial aspect. Familiarize yourself and your family or employees with the use of fire extinguishers, the location of emergency exits, and first-aid procedures. The more prepared we are, the better our chances of survival during an emergency.

Week 2: Slips, Trips and Falls

The second week of National Safety Month focuses on preventing slips, trips, and falls – some of the most common causes of serious work-related injuries and deaths. These incidents can occur in any setting, from home to office to outdoor environments.

Good housekeeping is key: ensuring walkways are clear of clutter can significantly reduce the risk of falls. Wearing appropriate footwear also matters. Shoes should provide adequate traction and can prevent slips and trips. Finally, always be mindful of your surroundings, and don’t rush—taking your time can often prevent a potential fall.

Week 3: Heat-Related Illness

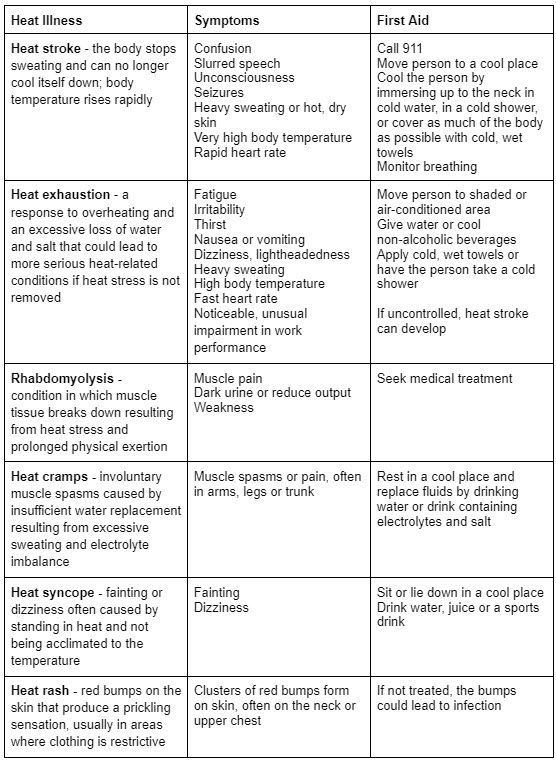

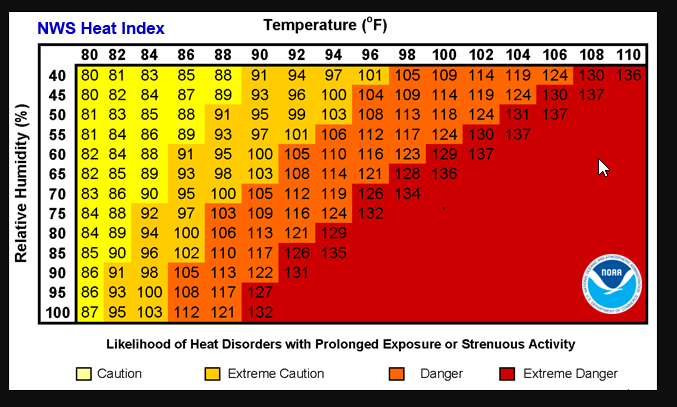

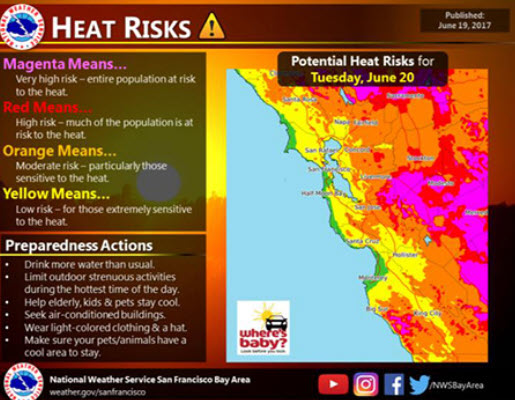

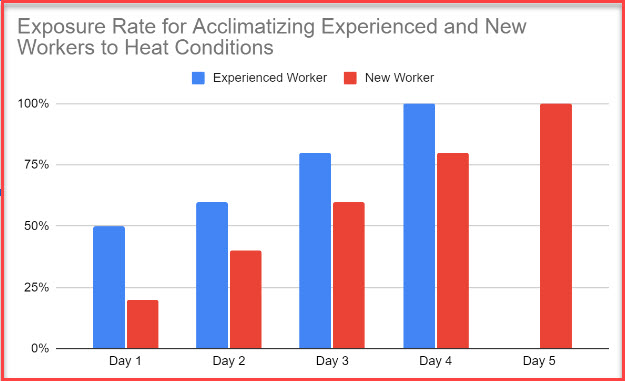

As we move into summer, the third week of National Safety Month emphasizes the dangers of heat-related illnesses, such as heatstroke and heat exhaustion. When it’s hot, make sure to stay hydrated by drinking plenty of fluids. Dressing appropriately is also important. Lightweight, loose-fitting clothing helps your body cool down.

Learning to recognize the signs of heat-related illnesses—such as heavy sweating, weakness, dizziness, nausea, and headache—can help ensure prompt treatment and recovery.

Week 4: Hazard Recognition

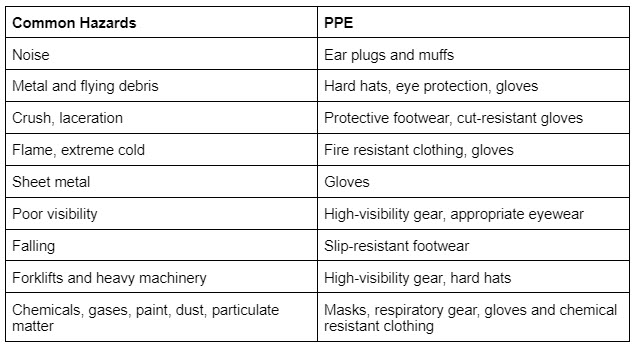

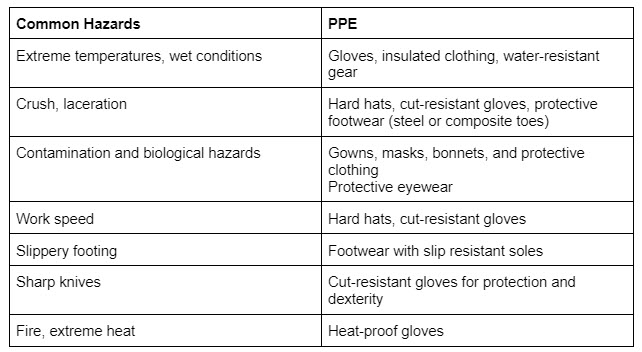

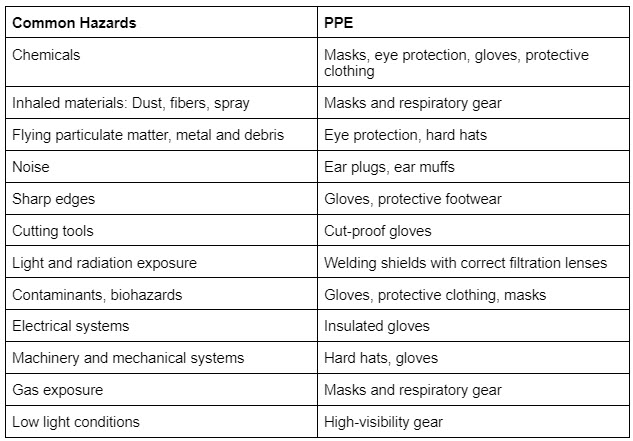

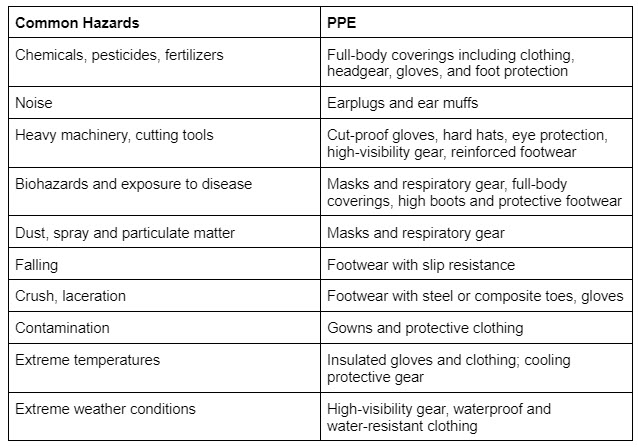

The final week of National Safety Month is devoted to Hazard Recognition. Whether at home, work, or in public places, being able to identify potential hazards can prevent accidents and injuries.

Safety audits can be useful in workplaces to identify potential risks. Look for things like unsecured materials that could fall, exposed wires, or unsafe equipment. Training and awareness are key to hazard recognition.

Safety is everyone’s responsibility

Let’s use National Safety Month to ensure we’re all doing our part to create safer environments. To make it easy, here are some key areas to check, first, along with some exceptional products.

1. The Importance of Hand Protection

Hands are among the most vulnerable body parts in the workplace. In order to prevent injuries, hand protection should be essential to ensure workplace safety. Let’s dive into the critical role of hand protection by highlighting Liberty Safety’s FroGrip® P-Grip Ultra-Thin Polyurethane Coated Gloves (4636TCG).

These gloves combine excellent dexterity with reliable hand protection, including a 13 gauge hi-vis green polyester shell and touchscreen compatible design. Workers perform their tasks with precision and confidence while wearing them.

Liberty Safety also offers a product line of gloves designed to resist cuts, abrasions, and punctures. These cut resistant gloves exemplify Liberty Safety’s commitment to offering advanced hand protection solutions.

By incorporating Liberty Safety’s hand protection gear into workplace safety protocols, organizations can align with the goals of National Safety Month, prioritizing employee safety and well-being.

2. Clear Vision for Safety: Liberty Safety’s Full-Frame Safety Glasses

Clear vision is essential to maintaining a safe working environment, particularly in hazardous conditions. That’s why it’s important to spotlight eye protection with products like Liberty Safety’s iNOX® AURA II™Full-Frame Safety Glasses (1764BG).

These glasses are meticulously designed to provide optimal eye protection without compromising vision clarity. Enjoy:

-

- Polycarbonate polarized lenses for maximum protection

-

- Soft non-slip adjustable rubber nose piece

-

- Anti-scratch coating

-

- Compliance: ANSI Z87.1+

Liberty Safety also offers safety glasses with features such as durable frames, distortion-free lenses, and anti-fog coatings. They enhance both safety and comfort for the wearer.

Our glasses not only protect your employees’ eyes from potential hazards but also contribute to creating a culture of safety and awareness in the workplace. They are particularly valuable in industries such as construction, manufacturing, and laboratories where eye protection is of utmost importance.

3. High Visibility, High Safety: Hi-Vis Apparel

Visibility plays a pivotal role in workplace safety, especially in high-risk environments. That’s why we focus on high-visibility safety clothing, featuring Liberty Safety’s HiVizGard™ Class 2 Hi-Vis Apparel (C16015GB).

These Class 2 garments are designed for workers near heavy traffic driving over 25 mph and in low visibility areas. Features include a front zipper closure and multiple pockets for convenience and functionality. This Surveyor’s Vest is meticulously designed with a black bottom. This strategic feature serves to conceal any accumulated dirt or grime, ensuring the vest consistently maintains a clean and professional appearance.

Liberty Safety’s Hi-Vis Apparel ensures that employees stand out. These garments are specifically designed to enhance visibility, making workers easily identifiable, even in low-light or high-traffic conditions. Reducing the risk of accidents and enhancing overall safety. These garments are available in various styles, including vests, shirts, jackets, and pants, catering to the specific needs of different industries and job roles.

4. Protecting Heads: Liberty Safety’s DuraShell® Hard Hats

The head stands as one of the most vulnerable body parts in potentially hazardous work environments, demanding reliable head protection. We highlight the crucial role of head protection by introducing Liberty Safety’s range of Hard Hats.

Crafted from durable materials and designed to meet stringent safety standards, Liberty Safety’s Hard Hats offer unparalleled protection for workers’ heads. These hard hats are available in various styles and configurations to suit different industry needs, ensuring a comfortable and secure fit for every wearer.

Consider the 1404R-HO DuraShell® Hard Hat by Liberty Safety. This hard hat provides robust head protection, ensuring safety and comfort with its sturdy design and adjustable features, making it an indispensable tool for any high-risk environment. Featuring:

-

- Shell constructed from high-density polyethylene

-

- Low-Profile design

-

- Pillowed brow pad & top ribbon pad for comfort

-

- Rain trough on sides and back of helmet channels moisture away

-

- Available in 4 suspension

-

- Compliance: ANSI Z89.1-2014, Type 1, Class C,G,E

Liberty Safety’s Hard Hats provide reliable protection for workers’ heads, providing a critical safeguard in inside or outside work environments.

Use this month and these resources to bring health and safety to the forefront of your day to day

National Safety Month serves as a powerful reminder of the importance of workplace safety. Liberty Safety, a trusted provider of top-quality personal protective equipment (PPE), wholeheartedly embraces this initiative.

Through their commitment to delivering innovative and reliable safety solutions, Liberty Safety supports organizations in their quest to create a safe and secure working environment.

Shop a vast assortment of safety supplies & worksite safety including cut resistant gloves for hand protection, safety glasses for superior eye protection, high visibility apparel, hard hats, and more. Provide your employees with high-quality, reliable PPE to protect against workplace hazards from LibertySafety – the brand you trust.

When it comes time to find the best selection of PPE for your workers, Liberty Safety can help. Contact us to learn more about our line of personal protective equipment for your safety concerns.