From steak dinners to backyard barbecues or bacon on the breakfast table, meat plays a significant role in the diet of U.S. consumers.

According to figures from the USDA, consumers in the U.S. were expected to have access to more than 224 pounds of meat and poultry per capita in 2022.

Workers in the meatpacking industry are the ones who handle all the stages from slaughtering to butchering to packaging that go into making that volume of meat available to consumers. The labor-intensive jobs of meatpackers are among the most dangerous jobs in the country, with a high risk of injury from many different sources.

We’ll take a look at some of the main types of PPE that workers need in order to be protected against injury on the job.

What Is Meatpacking?

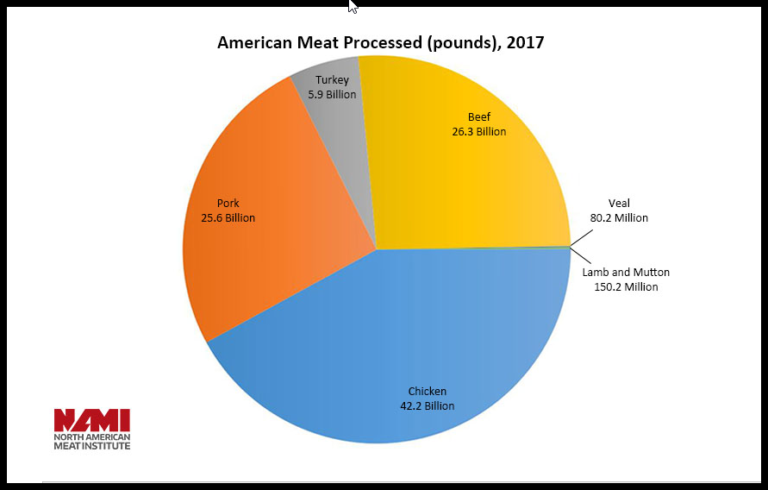

Meatpacking encompasses the range of activities and occupations involved in slaughtering cattle, pigs, sheep and other livestock for meat that is then cut, processed, inspected and packaged. The North American Meat Institute provides a breakdown of the volume of each category based on pounds processed.

Looking at the numbers another way, in 2023, the market size of the Meat, Beef and Poultry Processing industry is $295.9 billion.

And producing this volume of meat involves the work of many: 578,794 people employed to do the labor-intensive work involved in meatpacking and processing.

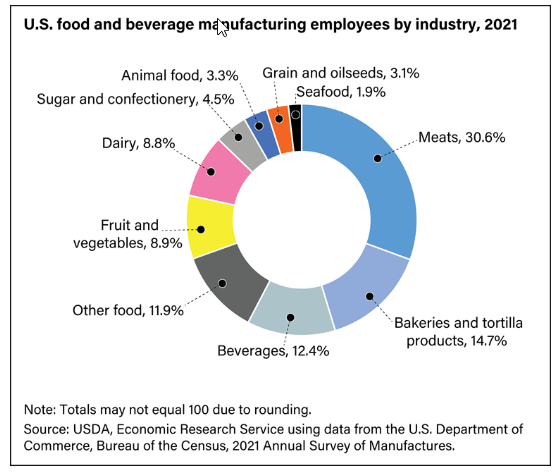

As part of the U.S. food and beverage manufacturing industry, USDA figures indicate that the employees working in meat production make up 30.6% of the total employment.

Each stage in the process from handling live animals to slaughtering, butchering, and various stages of processing, has its own set of hazards, but many aspects of working conditions are common across a range of occupational settings.

General Working Conditions in Meatpacking

The industry is labor intensive, and workers are commonly exposed to a variety of severe injuries as well as musculoskeletal disorders from repetitive motion, lifting, and overexertion. Workers in slaughterhouses come in direct contact with live animals and may be exposed to infectious diseases and biological agents, as well as the possibility of being injured by an animal.

Within the meatpacking facilities, loud equipment noise and crowded working conditions are typical. The pace of work is fast and often workers are positioned close enough together that neighboring workers could injure each other by mistake.

Facilities are filled with noisy, dangerous machines: saws, knives, bone-cutting tools, and other specialized equipment. Within this setting, floors and surfaces underfoot are often made slippery by water, blood, and grease, creating a slip and fall hazard for workers moving rapidly and surrounded by the constant presence of sharp tools.

Hoisted overhead are heavy carcasses to be butchered, also moving through the facility. Workers often operate in the cold conditions necessary for meat storage, such as refrigerated processing areas and warehouses. They also are exposed to toxic substances in the form of cleaning chemicals and chemicals that make up the refrigeration and chilling systems.

PPE for Meatpacking Protects Against Specific Hazards

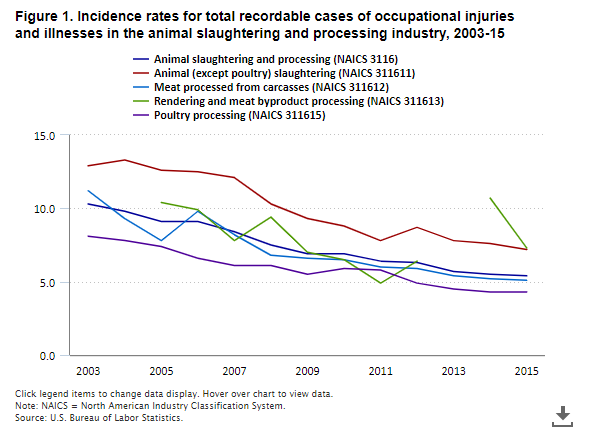

On the whole, the meatpacking industry has an illness and injury rate higher than those of manufacturing or private industry, reports the Bureau of Labor Statistics. Identifying and using the right PPE is vital to the health of workers.

1. Head Protection

Head protection is necessary for many workers. Hoists, shackles and hooks are used in lifting carcasses overhead so they can be transported from one station to the next throughout the facility.

Workers could be hit by carcasses as they move or if the equipment transporting them fails and causes them to fall. Hard hats protect against unintended contact with other overhead objects as well as tools being used by neighboring workers.

2. Eye Protection

Protective eyewear helps prevent workers from sustaining eye injuries caused by flying fragments of bone from the cutting or trimming process. They also protect the eyes from cleaning chemical splashes during mixing or application, dirt, and splashes of fluid that could carry disease.

3. Face Protection

Cleaning equipment involves powerful chemicals; when mixing or handling these and other chemicals, face shields provide protection from burns and other injuries. When working with live animals, face shields provide protection from germs and infectious diseases, especially those transmitted by exposure to animal blood or feces. Extra care is needed when handling animals that are ill, and once again, face shields offer a necessary layer of protection.

Germs, bacteria, toxins and chemicals all have the potential to do serious or permanent harm to workers and can easily enter the body through inhalation. Diseases can be spread from animal to human; toxins and chemicals like ammonia, used in refrigeration systems, can cause burns and irritation in breathing unless workers use adequate masks or respirators.

4. Hearing Protection

Hearing loss is a common problem in the meatpacking industry, but one that can be addressed with the right PPE. Machinery, band saws and other equipment generate high levels of noise that can damage hearing.

Ear muffs or earplugs can bring the noise level down to acceptable levels to reduce the wearer’s exposure to harmful sound and protect hearing. Liberty Safety can help you select the right protection for your application, such as DuraPlugs™ Metal Detectable Corded Single Use Disposable Foam Earplug.

DuraPlugs™ Metal Detectable Corded Single Use Disposable Foam Earplug

Super-soft, self-adjusting foam earplugs have a slow-recovery tapered shape for comfort and easy insertion and removal. Noise Reduction Rating (NRR): 32 dB Compliance with ANSI S3. 19-1974

5. Hand Protection

Purpose-suited gloves are a critical part of PPE for those involved in the meatpacking industry. Beyond high-powered cutting equipment, workers use sharp knives in close quarters, making them susceptible to cut injuries from their own knives or those of nearby workers. Wrist and forearm protection are important as well as metal mesh or cut proof gloves.

Very often meatpacking workers operate in cold and damp environments; gloves need to provide adequate protection from cold and moisture as well as enhancing grip. Correct fit is necessary to maximize dexterity and comfort.

Waterproof gloves are necessary to prevent workers from biological hazards and infectious diseases especially when working with animals. When working with cleaning or other chemicals, gloves should be chosen for resistance to the specific hazards in order to protect workers from chemical burns and a variety of skin irritations or diseases.

Protection from heat is needed as well for workers involved in packaging operations working with heat sealing equipment.

Choosing the right glove for the purpose is critical. Liberty Safety has the expertise to help you match the glove to the job and specific type of hazard exposure.

Green Nitrile Gloves

Unlined 15 mil gloves, 13” length, with embossed grip on palm and fingers.

6. Foot Protection

The correct footwear is a vital part of worker safety in meatpacking. Wet, slippery surfaces underfoot are common. Footwear needs to be nonslip to protect workers from slips, trips, and falls on wet, greasy surfaces. Steel toe footwear protects workers from crush injuries from contact with heavy carcasses, equipment, and tools. Working around chemicals or animals, boots and footwear also need to be waterproof to keep the wearer safe.

DuraWear™ Steel Toe PVC Boots

16” length with steel safety toe. One piece injection molded black high molecular PVC compound with bar cleat outsole.

7. Protective Apparel

Exposure to germs and bacteria as well as toxic chemicals can be prevented with the full-body protection of coats and coveralls. Coverings protect against infection and, as in other food-related industries, are part of the standard food safety hygiene to protect meat from contamination that could harm consumers. When mixing or applying chemicals, aprons may be needed in addition to coats or other full-body protective gear, to avoid burns or other injuries from splashes.

PolyGard™ Medium Weight Lab Coat

Constructed of SpunBonded Polypropylene with a snap front closure and elastic wrists, the PolyGard™ Medium Weight Lab Coat offers superior breathability, extended wear, and complies with federal regulations for food contact.

Staying Safe in the Meatpacking Industry

Orientation and training are two of the most important factors in protecting workers. Ensure all workers, especially young or new workers, are aware of the hazards and provide clear instructions in how to use PPE.

Involve the employees in the process. Workers must be consistent in wearing PPE and correct fit is critical. Proper fit and function allows the worker to do the best job possible with the greatest degree of comfort. Freedom of movement is needed to allow stretching and bending, but flapping, oversized garments create an unacceptable risk around machinery.

The technical experts at Liberty Safety are always available to help you identify the right fit and appropriate performance specs for the task at hand.