Personal protective equipment (PPE) is frequently worn to prevent bacterial or viral cross-contamination and exposure to harmful environmental pollutants. Depending on the industry and the level of exposure, it is recommended for workers to use a complete set of protections, including gloves, masks, goggles, and coveralls.

In some cases, it goes beyond just a recommendation. According to the Occupational Safety and Health Administration (OSHA), every facility should establish protocols and provide education on the PPE required. As part of that, workers should also be aware of how to safely put each garment on (donning) and take off (doffing).

Importance of Correct Donning and Doffing

Proper use (and therefore proper donning and doffing) of PPE affects the safety of the workers and those around them. The primary goal is to create a barrier from biological and chemical hazards starting from the moment the wearer puts it on to when each piece of PPE is removed.

General Sequence

The CDC provides the following general overview for putting on and removing PPE that is commonly worn together.

DONNING

- Perform hand hygiene

- Put on shoe covers (if applicable)

- Put on coveralls

- Put on mask/respirator (if applicable)

- Put on eye protection (if applicable)

- Put on gloves

DOFFING

- Remove shoe covers (if applicable)

- Remove gown and gloves together*

- Perform hand hygiene

- Remove eye protection (if applicable)

- Remove mask/respirator (if applicable)

- Perform hand hygiene

Recommended Donning and Doffing for Specific Garments

Protect your workers and provide a safe working environment with the following recommended steps for each piece.

Masks

Because they are designed to help reduce the wearer’s exposure to airborne particles, and unwanted particulates, wearing a face mask helps keep a worker safe in possibly contaminated environments.

Donning

Step 1

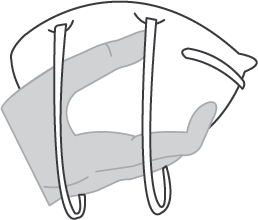

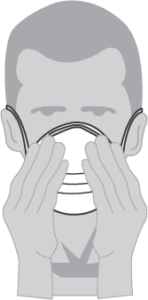

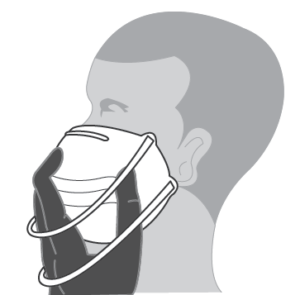

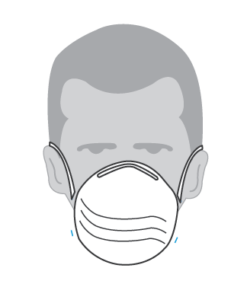

Hold the respirator in hand with the nose piece at your fingertips, allowing the headbands to hang freely below your hand.

Step 2

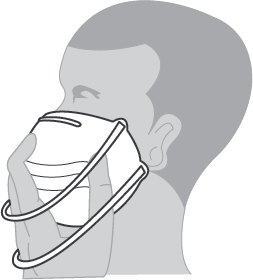

Press the respirator firmly against your face with the nose piece on the bridge of your nose.

Step 3

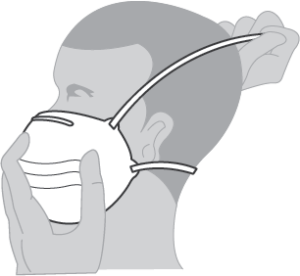

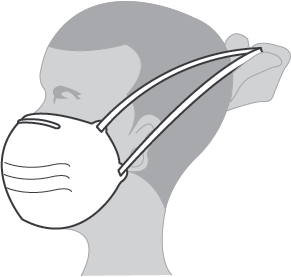

Stretch and position the top band high on the back of your head. Stretch the bottom band over your head and position it below your ears.

Step 4

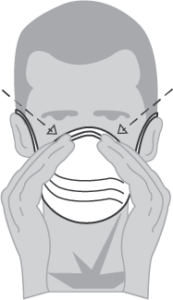

Using both hands, mold the nose piece to the shape of your nose.

Step 5

Test the fit by cupping both hands over the respirator and inhale vigorously. Avoid disturbing respirator position. If air leaks around the edges, reposition the straps or adjust strap tension.

Doffing

Step 1

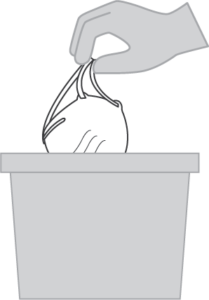

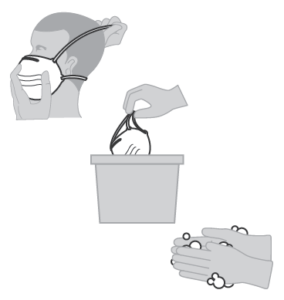

Without touching the front of the respirator, lean forward and gently remove the mask from behind by sliding both ties up and over your head.

Step 2

Immediately discard the respirator in a waste container or other appropriate receptacle.

Step 3

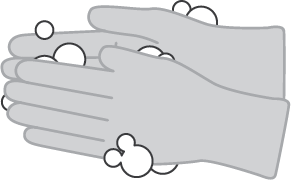

Thoroughly wash hands for 20 seconds with warm soap and water, or hand sanitizer with a 60% alcohol content if water is unavailable.

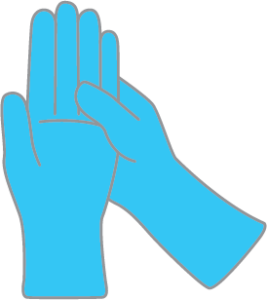

Gloves

Chemically resistant disposable gloves should extend past the wrists for better protection. Certain types of material will only be suited for specific chemicals or biological elements. It’s important to check the manufacturers’ instructions.

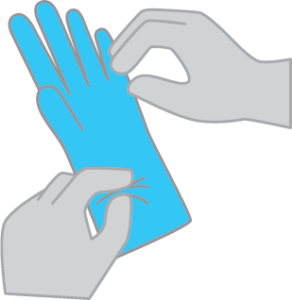

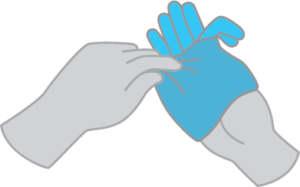

Donning

Step 1

Remove a single glove from the box. Avoid touching multiple gloves or glove fingertips to reduce the risk of accidental contamination.

Step 2

Check the glove to ensure there are no rips or tears. If there are, discard the glove immediately. Align the fingers and thumbs of the glove to your hand.

Step 3

Carefully insert your hand into the glove, pulling the cuff over the wrist.

Step 4

Repeat steps 1-3 to don a glove on the opposite hand. Ensure proper glove fit and cuffs are snug to the wrist.

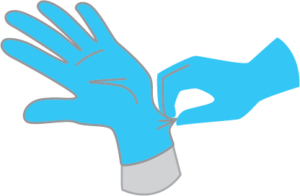

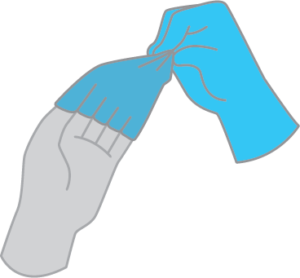

Doffing

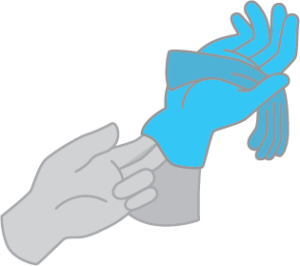

Step 1

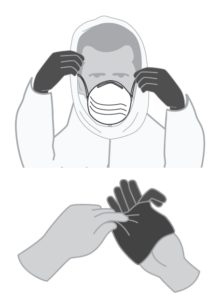

Grasp the outside of the glove near the wrist.

Step 2

Peel the glove away from your hand, turning it inside out.

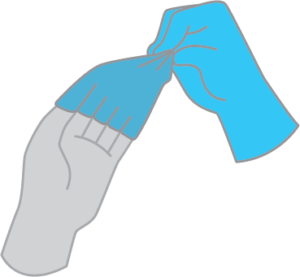

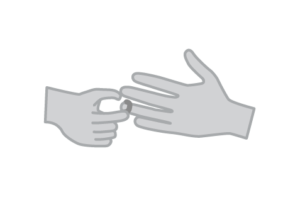

Step 3

Holding the removed glove in your gloved hand, carefully slide an ungloved finger into the wrist of your gloved hand. Avoid touching the outside of the glove.

Step 4

Peel the glove off from the inside, creating a “bag” containing both gloves. Discard gloves immediately and appropriately.

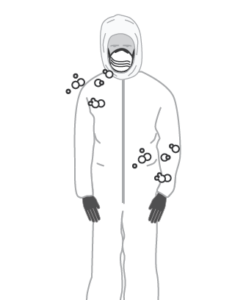

Coveralls

To reduce both chemical and biological contaminant exposure to the skin, workers should wear disposable coveralls. When worn correctly, they can provide the needed safeguards for most conditions.

DuPont™, an industry leader in safety and safety products, offers a broad portfolio of DuPont Personal Protection. They recommend wearers inspect their coveralls at the following times to determine that the suit has not been damaged or compromised:

- Immediately upon receipt from the supplier.

- Before it is placed in service to be worn.

- After a garment is worn and before the garment is placed in service to be worn again. (Do not use contaminated, damaged, or altered garments.)

- Inspect annually.

They suggest the following don/doff procedure for their TYCHEM® NON-ENCAPSULATED GARMENTS (for complete details, including a maintenance schedule, as well as the limitations of use, visit the DuPont website.)

Donning

Step 1

Remove personal clothing, jewelry (including watches), and personal items like pens, key rings, badges, etc.

Step 2

Visually inspect the entire set of PPE, including outer boots if applicable, and ensure the size suit meets your requirements.

Step 3

Put on boot covers. Note: if coveralls have attached booties, they are to be worn inside outer boots.

Step 4

Insert your feet into the leg of the coverall and slip your foot into the attached sock (if applicable). Extend leg to maximum while pulling coveralls up.

Step 5

Put on outer chemical boot if attached. If boot flap covers are included as well, then first pull covers up and then don your outer boots. Pull the boot flap covers down over the boot as far as it will go.

Step 6

Pull the coveralls to your hips.

Step 7

Put arm into first sleeve and pull the coverall sleeve to your shoulder. Ensure your hand is securely inside the glove if attached. Repeat with opposite arm.

Step 8

If gloves are not attached, don your gloves. Pull the sleeves of the garment over the gauntlet of the gloves.

Step 9

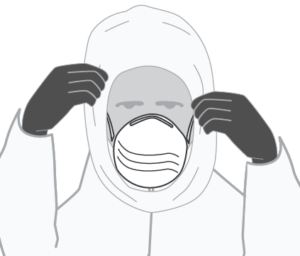

If mask or respirator is required, don that face piece now and check its function.

Step 10

If present, pull the hood up over your head and make sure not to disrupt the mask/respirator.

Step 11

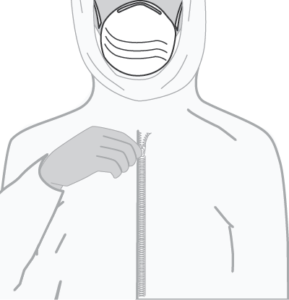

Close the overall zipper carefully and secure the flaps over the zipper if they are included.

Doffing

Step 1

If your garment has been contaminated or is suspected of being contaminated, you must first undergo field decontamination before removing the garment.

Step 2

Continue to use your respirator until the garment has been doffed and removed.

Step 3

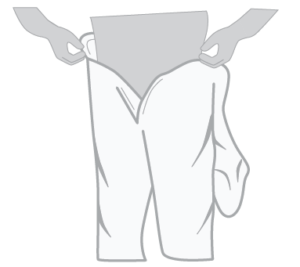

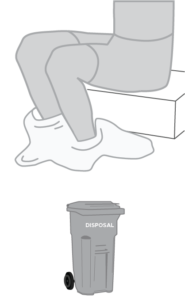

While standing, open the zipper flaps (if present) and then open the zipper.

Step 4

Peel the hood (if present) off your head and down and away from your shoulders to avoid contaminating your inner clothing or skin. Remove your arms from the sleeves. If separate gloves are present, remove them being careful to avoid cross-contamination of inner clothing or skin.

Step 5

Lower the garment to below your hips and sit down if possible. Do not touch the outside of the garment, as it may be contaminated. Remove your outer boots (if present), then pull the garment off your legs. Carefully take the garment away from the doffing area and dispose of it appropriately.

Step 6

Once the garment has been completely removed you can doff the respirator.

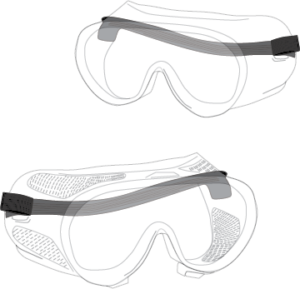

Safety Eye Protection

Safety goggles are routinely needed for those working around chemicals like pesticides. A snug fit helps prevent any possible irritants from getting into the eyes.

Donning

Step 1

Ensure appropriate fit and vented preference (non-vented goggles prevent splashes or sprays from irritating the eyes).

Step 2

Remove safety goggles/glasses from package or storage container.

Step 3

Place eye protection directly on your face. Avoid setting them down on any surfaces prior to.

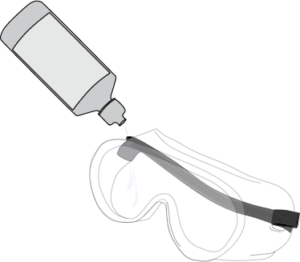

Doffing

Step 1

If wearing gloves, remove gloves before removing safety goggles.

Step 2

Remove eye protection and avoid touching your eyes or face.

Step 3

Clean safety glasses or goggles with the manufacturer’s suggested solution. Let dry before storing them.

Step 4

Place cleaned eye protection in clean container or disposable bag for reuse.

All personal protective equipment should be safely designed and constructed and should be maintained in a clean and reliable fashion. It should fit comfortably, encouraging worker use.

At Liberty Safety, we want to help you find the most appropriate protective equipment for your team. We provide high-quality PPE clothing and safety gear designed for a variety of environments. Get in touch today and learn more about our full selection of personal protective equipment.