It’s been a very good year! 2022 brought several exciting changes for us, including a name change, an upgraded website, and our full product catalog release. But before we say goodbye to it, we wanted to showcase some of our favorite and most popular products of 2022.

From cut resistance with touchscreen compatibility to innovative coated gloves, each product represents practical, quality protections for most work environments. Below we’ve listed our top ten, and highlighted the features that make them great.

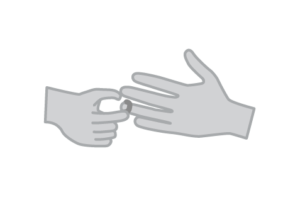

Gloves Are Always a Staple for Worker Protection

Hand injuries are a genuine hazard in any workplace. While manufacturing and industrial facilities see higher rates of hand injuries, any worker in any industry can experience them. That’s undoubtedly why they are in such high demand from our customers and why we always have such a wide range available.

In addition to a good fit, work gloves that were abrasion resistant, independently third-party tested, and industry-specific were some of our most highly requested items in 2022 and included:

A-Grip® Black Latex Coated Seamless Gloves

Along with the superior grip of a nitrile coating, this glove offers you the additional strength of a nylon/polyester knit shell. The A-Grip™ Black Latex Coated Glove is a comfortable glove built for jobs specific to manufacturing settings. Sizes XS – 2XL

These gloves have excellent flexibility, elasticity, and durability for a superior fit. It provides:

- 13 gauge seamless cotton/polyester knit shell

- Textured black latex coating for superior grip in all conditions

- Comfortable knit wrist with color-coded hems for size identification

- Breathable back for everyday use

- Machine washable

- Ideal for agriculture, durable goods assembly and box handling

Z-Grip® Black Microfoam Nitrile Cut Resistant Gloves

2022 saw protective coatings with cut resistance as a sought-after choice. Nitrile will continue to be an excellent coating choice for durability without compromising agility and fit. Sizes S – 2XL

The Z-Grip™ Black Microfoam Nitrile Cut Resistant Glove is exceptional quality for value. Our customers say it provides reliable protection from abrasions and can be worn comfortably for prolonged periods as a general-purpose glove. You’ll also get the following:

- ANSI A4 for high-cut resistance protection

- 13-gauge engineered yarn shell for superior comfort

- Black micro-foam nitrile coated on palm and fingers for abrasion resistance

- Offers breathability and optimized grip

- Reinforced nitrile-coated thumb crotch

Ultra-Z® Gray Proprietary Foam Cut Resistant Gloves

Beyond cut resistance, customers in 2022 were also looking for innovative coatings that provide comfort, durability, and the ability to work in both wet and dry conditions. The Ultra-Z™ Gray Proprietary Foam Cut Resistant Gloves checks all those boxes. Sizes: S – 2XL

Workers who chose these gloves also needed a multi-purpose foam-coated glove with an A4 cut rating. They also are touchscreen-compatible for even more convenience. They also feature:

- 18G seamless shell with superior comfort

- High tensile strength to weight ratio

- Non-slip, minimal lint, breathable

- Durable, washable, reusable

- Colored hem cuffs for easy size identification

- Ideal for electronics, glass cutting and construction

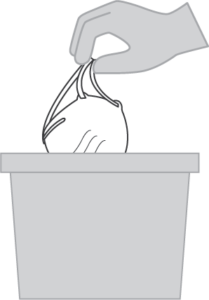

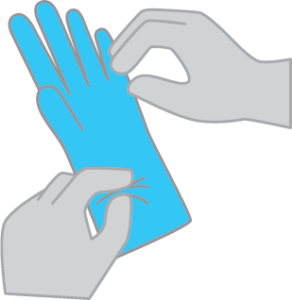

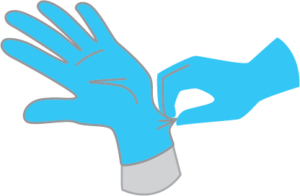

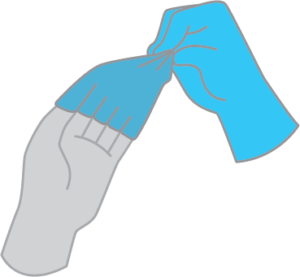

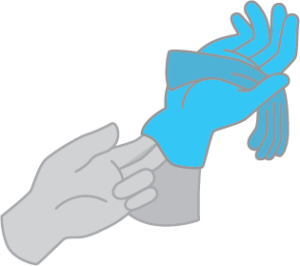

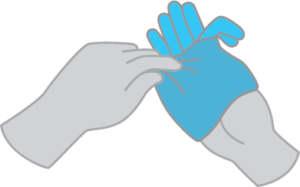

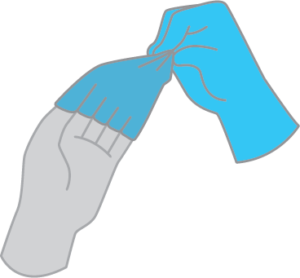

DuraSkin® Orange Nitrile Disposable Gloves

For those focused in cross-contamination environments, our DuraSkin® Orange Nitrile Disposable Gloves come in an easy-to-use 100 glove dispenser and can simply slide on. Made with 100% nitrile, they’re gloves that are made for those jobs that require specific sanitary considerations. Sizes M – 2XL

They’re ideal for food handling, janitorial, and general purpose and are:

- Ambidextrous

- Diamond textured for extra grip

- Compliant with federal regulations for food contact

Regular Full Feature Leather Palm Gloves

Our Regular Full Feature Leather Palm Gloves are made of split cowhide leather with a canvas back, perfect for workers who do heavy material handling and protection against light punctures. Sizes S – XL

The cotton palm inner lining can’t be beaten to stay cool and comfortable. It’s made for performance and protection. The design includes:

- Gunn pattern

- 2½” rubberized cuff

- Knuckle strap

- Wing thumb construction

- Ideal for general work, construction, concrete

Looking Good Without Compromising Safety Compliance

In 2022 the industry readily offered style and function with products that looked good and still in safety compliance.

And though they have been around for a long time, safety glasses and vests were one of those products that really stepped up their game. Both took on more of a sleek, sporty look, using stylish and highly visible colors for areas where workers need to be seen.

Our best-sellers were:

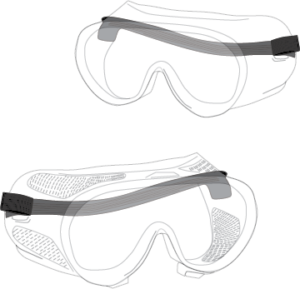

Aura™ Gray Full Frame Safety Glasses

The Aura™ Gray Full Frame Safety Glasses are some of the best in trendy eyewear protection. The scratch-resistant polarized lenses filter UVA and UVB rays better than regular tinted lenses. They also provide exceptional glare reduction that enhances clarity and definition in bright work environments. One size

Simple to slip on and off, and can be worn during and off work hours. They feature:

- Polycarbonate temples and single-piece wrap-around lens

- Scratch-resistant polycarbonate lens

- Lenses filter 99% of harmful UVA & UVB rays

- Soft rubber nose pads and non-slip rubber temple tips

- Ideal for construction, oil rigs, shipyards

HiVizGard™ Class 2 Foreman Surveyor’s Vest with Black Bottom

Are you looking for your next hi-vis vest to have pockets, fit, durability, and be washable? The ANSI compliant HiVizGard™ Class 2 Solid Front Mesh Back Foreman Surveyor’s Vest with Black Bottom features all that and more. Sizes S – 6XL

This vest also offers many multiple-sized pockets along with broad silver reflective stripes that give you comfort, style, and functionality along with:

- Non-conductive and non-caustic zipper front closure

- One outside left chest pocket

- Black bottom front to conceal dirt/grease

- Ideal for assembly, traffic control, utility work

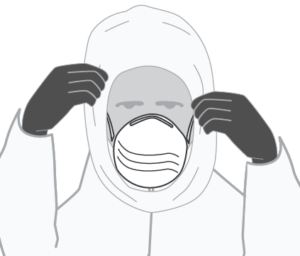

Practical, Effective Functionality is a Priority

The best worker protection is PPE that is comfortable, convenient, and will be worn every time. That’s why no matter the year, safety specialists are careful to choose protections that best fit their workers’ working environment and prioritize worker comfort.

The following products were designed with both of those requests in mind.

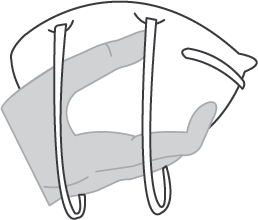

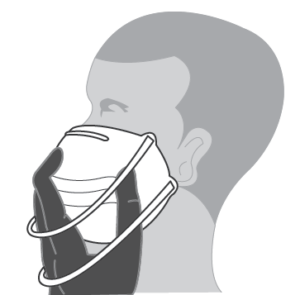

DuraPlugs™ Ear Muffs

DuraPlugs™ Ear Muffs are made from sound-attenuating materials and padded ear cups for a secure fit without compromising comfort. One size

These ear muffs work well in manufacturing facilities because they’re lightweight but rugged. The foam-filled and padded ear cups are highly effective in minimizing noise. It’s hearing protection that offers:

- High-performance ear muff offers excellent noise reduction

- Foldable for storage and lightweight design provides all-day comfort

- Adjustable cup on each side to adjust for a snug, comfortable fit

- 3-position adjustable headband

- Noise reduction rating (NRR) 34dB

- Ideal for construction, manufacturing, warehouse

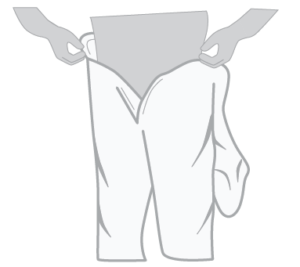

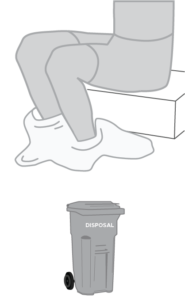

PolyGard™ Shoe Cover

Our PolyGard™ Shoe Covers offer non-hazardous particulate protection for environments that call for it. They boast a superior breathability and are durable enough for extended wear without losing any comfort. One size

You’ll also get:

- Non-skid treading

- Elastic top

- Non-latex

Durawear™ Cooling Towel

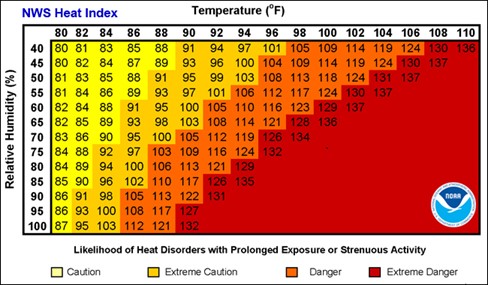

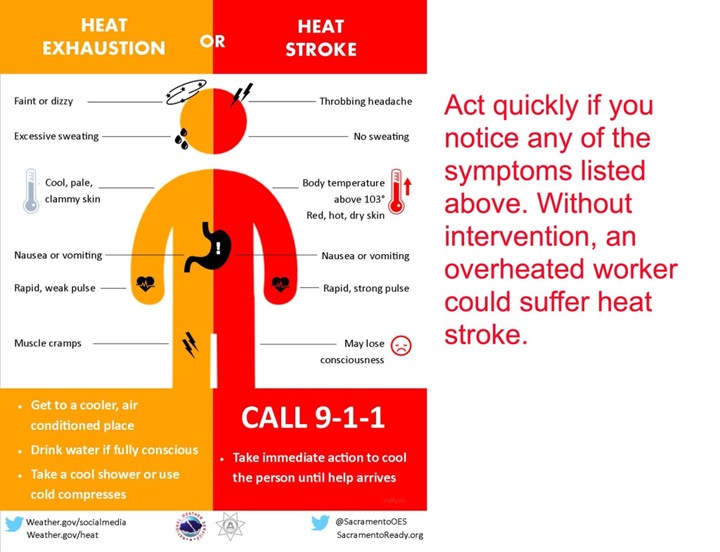

When you work in an extra hot environment, it feels good to reach for a towel that will mop the sweat from your brow and bring your temperature down. The Durawear™ Cooling Towel is made with that in mind. It is designed with an advanced Poly Vinyl Alcohol (PVA) material that is also antimicrobial-treated to prevent mold build-up. One size (26” x 16.5”)

The cooling effect is activated by soaking it in water for 2 to 3 minutes, wringing out excess water, and wrapping it around your head or neck. Some workers find it effective to wipe it on the pulse points of their body as well.

- Lightweight super-absorbent material

- Keeps cool for more than 5 hours depending on humidity levels

- Storage container; store towel in between uses to keep it clean

- Safe and reusable; Machine washable

Helping You Plan for a Safe Future

Comfort and safety never goes out of style. When personal protective equipment lives up to those expectations, you can plan on better buy-in from your workers and a safer work environment.

Liberty Safety is dedicated to providing quality, comfortable products that meet those needs. And we work to offer that at a competitive price.

If you’re planning on fulfilling your workers’ PPE orders in the New Year, download our Full Product Catalog and review our complete line. Then get in touch, we’re happy to help you find everything you’re looking for.