Hand injuries are a genuine hazard in any workplace. While manufacturing and industrial facilities see higher rates of hand injuries, any worker in any industry can experience them. Knowing the fundamentals and keeping essential hand safety tips in mind is a great way to protect yourself. After all, the best kind of protection is prevention.

Tip 1: Be aware of the hand injury risks in your work environment

According to the U.S. Bureau of Labor Statistics, your hands are one of the most common body parts to be injured in the workplace (second only to your back). Being aware of the risks within your workplace environment means you’ll better avoid any harm to yourself or others.

Identify potential hazards by knowing the main risks to look out for:

- Personal: Hazards caused by something you might be wearing are considered a personal risk. This could be a watch, ring, clothing, or even ill-fitting personal protective equipment.

- Mechanical: A mechanical risk involves some type of moving parts where hands or fingers could be pinched, cut, severed, etc. It could also be a situation where objects could fall and crush the hands or cause other such damage.

- Contact: Anything your hands come in contact with, including chemicals, high temperatures, and sharp edges, puts them at risk for injury. Because it involves a multitude of objects and situations, contact hazards cause most workplace mishaps.

Tip 2: Learn about hand safety policies in your workplace

Once you identify the different hazards you may be exposed to during your day, you’ll need to find a way to minimize the risk. Your employer should provide workplace safety training as an important component in knowing what steps to take. Hand safety training should include:

- Worker Education – Effective hand safety means having current and readily available documentation for equipment, work protocols, and emergency response. Training should also include learning the procedures for accurate injury reporting.

- Equipment Use – Beyond a manual, workers should be shown how to handle equipment they will use and be around. Physical safety guards or other emergency controls should be installed and inspected regularly.

- Supportive Staff – It’s essential that you and your co-workers are given the tools to succeed. This involves an administrative staff that supports a workplace culture of safety and helps minimize risks for everyone.

Tip 3: Choose and wear the correct hand protection apparel

OSHA reports that 70% of hand injuries occur when people are not wearing gloves. The same report says that for those workers who wear gloves, 30 percent of them don’t wear the right kind of glove for the task.

When using PPE for your hands, knowing the what, when, and how is particularly important.

- What type of glove is best for the work?

- When should the glove be used?

- How should the glove fit and be maintained?

Of course, the glove can’t work if it isn’t worn. A work environment that encourages glove compliance means:

- Improved overall hand safety

- Reduced rate of hand injuries

- Reduction in costs related to hand injuries

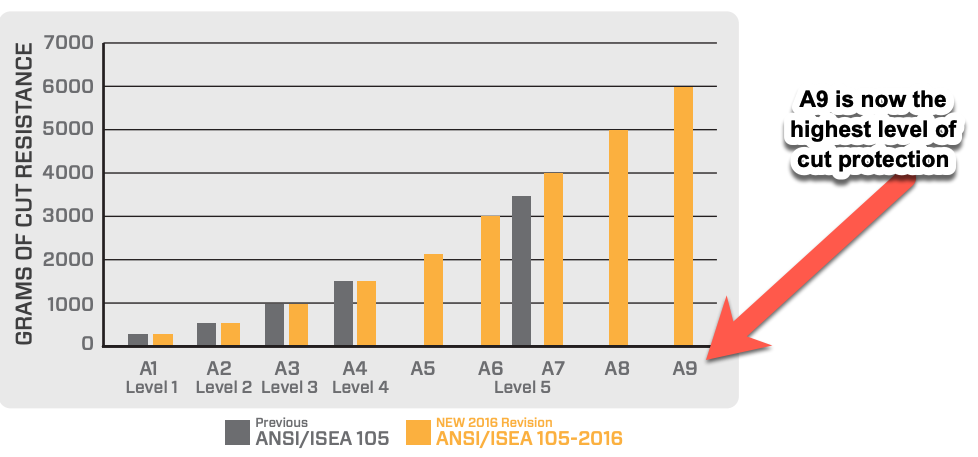

The International Safety Equipment Association (ISEA) offers downloadable guides on choosing hand protection. The guides follow the ANSI/ISEA (American National Standard for Performance and Classification) standards for impact and cut-resistant gloves.

Understanding the glove ratings is essential when choosing the correct level of hand protection needed for your workplace.

- Levels A1, A2, A3 offer protection against scrapes.

- Levels A4, A5, A6 offer protection against injuries for which stitches would be required.

- Levels A7, A8, A9 offer protection against the most serious injuries.

Buying your gloves from a reputable supplier means you’ll have access to reliable products and customer support that can help you choose the best glove for your needs.

Tip 4: Take personal responsibility to prevent injuries

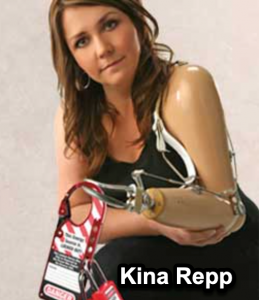

“You are your last line of defense in safety. It boils down to you.” — Kina Repp, workplace accident survivor and safety and motivational speaker

Kina Repp survived a serious workplace accident that resulted in the loss of not only her hand but her entire left arm. She now presents safety talks to employers and employees. Her message addresses the importance of training, safety procedures, and personal responsibility.

In Kina’s case, lack of experience which caused her to miscalculate the risks involved, was the major contributor to her accident. At the time, Kina also fell into the group that is statistically most at risk for injuries, new hires.

According to the U.S. Bureau of Labor Statistics, the good news about that statistic is that the longer employees are on the job, the lower the injury rates become.

However, unsafe behavior doesn’t always change because of experience or even as we grow older. Our behavior will only change if how we think, feel, believe, and prioritize our own personal safety changes.

You can show others that you value your personal safety and take responsibility for it at work by:

- Getting involved: Make safety a personal thing for you by being active in the overall safety of your company. That means being aware of and helping others avoid dangers. It also means reporting accidents and near-misses, so the company is made aware of any risks.

- Committing to learning: Read up on and learn your company’s safety procedures. They were created specifically for your environment to keep you safe. Often, they’ve considered past accidents and injuries so that you can learn from others’ mistakes injury-free!

- Displaying safe behavior: We often let those around us set the standards. If we see others not following the rules, it permits us to do the same. It is also true that we can do the opposite and positively influence workplace safety by displaying safer behavior.

A work environment that helps us avoid a hand injury is something we all should expect. But, ultimately, it’s up to us. By practicing these hand safety tips, you’ll not only protect yourself but those around you too.

For more information about hand safety and the gloves that can protect you, contact Liberty Gloves and Safety. Download our catalog and discover more of the PPE products we offer.