A wide variety of trades and occupations are considered part of the construction industry. But one common thread exists: Every sector needs PPE to keep construction workers safe.

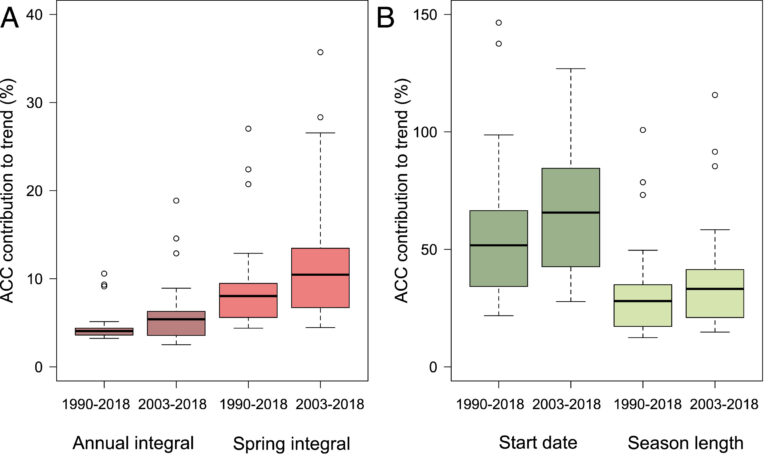

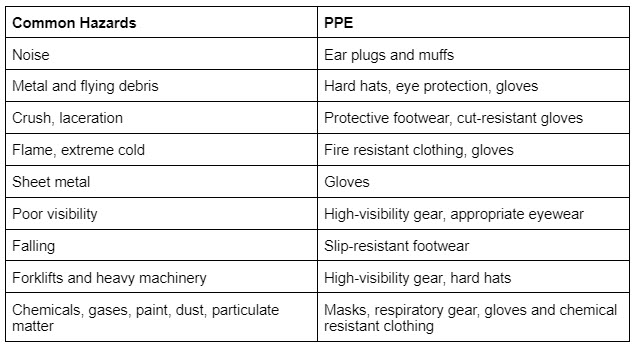

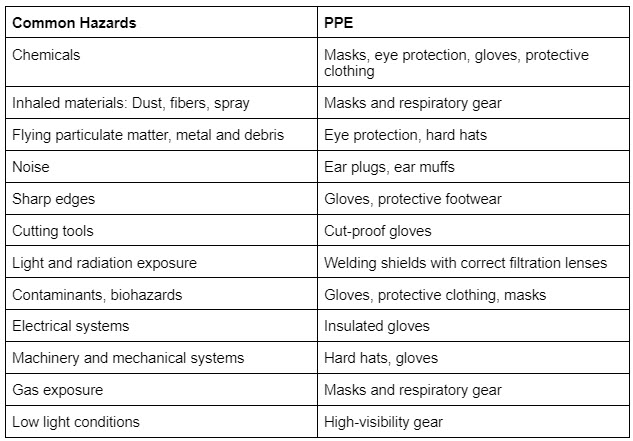

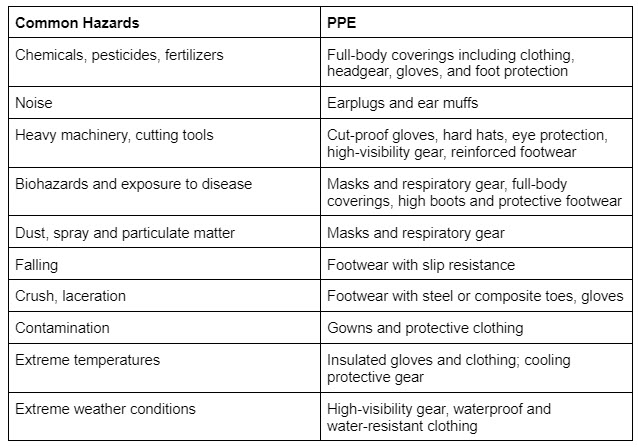

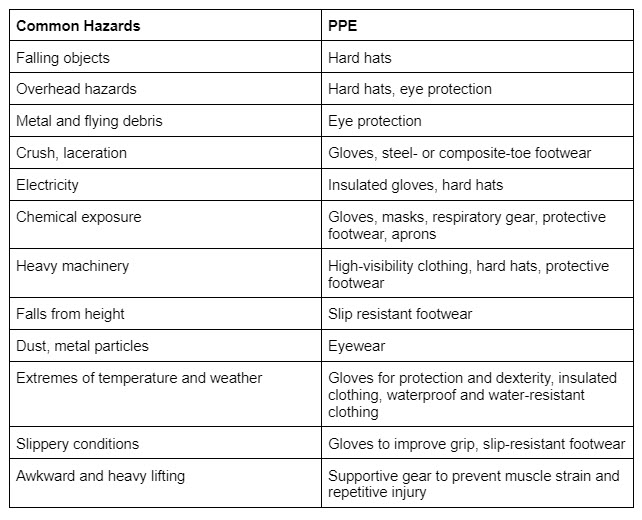

The hazards workers face on a daily basis may be related to the worksite itself or specific trades and activities. Materials used in certain types of construction or by particular trades also present hazards. Some other hazards are universal.

In this post, we’ll take a look at the main types of PPE used throughout the construction industry and why they are needed.

Construction Environments and Occupations

The built environment is everywhere: Homes, factories, roadways, dams, skyscrapers, drilling platforms, hotels and an endless list of structures.

Residential, commercial and industrial construction involve widely variable worksites and settings, from demolition, excavation and road work to specialized installations, high rise structures, and other extreme conditions.

A multitude of roles and occupations are involved in construction, including these:

- Structural ironworker/steelworker

- Heavy equipment operator

- Construction laborer

- Elevator installer or repairer

- Sheet metal worker

- Plumber

- Carpenter

- Roofer

- Glazier

- Boilermaker

- Electrician

- Drywaller

- Painter

Construction PPE from Head to Toe

Job descriptions and working conditions vary, but what all these occupations have in common is the routine exposure to hazards and with that, the need for personal protective equipment to guard their health and safety.

From head to toe, construction PPE is critical for preventing injuries and cumulative heath damage from long-term exposure to environmental conditions, chemicals, and respiratory irritants including these hazards common to construction sites:

- Chemicals

- Dry Heat

- Fire

- Electricity

- Construction Equipment

- Chainsaws and other bladed tools

- Slippery surfaces

- Bright lights

- Wood or metal chips

- Heights

- Extreme noise

- Flying or falling objects

Contact with objects and poor visibility are ever present as well. Let’s start at the top and consider the types of protection that may be needed.

Head Protection

The hard hat is the iconic symbol of the construction industry—for good reason, as they protect the head from injury. The wearer is protected from fixed overhead objects and projections, objects that could be falling from above and flying objects such as debris from a fabrication process. Hard hats also offer insulation from electric shock.

Head protection is available in different styles and materials at Liberty Safety. In general, the hat’s purpose is to absorb shocks, including those which, according to an article in Safety+Health, could cause brain injuries.

For optimal protection, ensure correct fit and don’t allow anything to interfere with the hat’s suspension. As with other PPE, inspect your hard hat routinely for damage. If it’s damaged, don’t use it.

Eye Protection

The National Institute for Occupational Safety and Health reports that construction has a higher rate of eye injuries than any other occupation. Flying particles, chemicals, dust, wood chips, metal shavings, acids and caustic liquids are frequent hazards, not to mention the potential hazards of impact with larger objects on site.

Wearing the appropriate protective eyewear can prevent 90% of serious eye injuries, according to the American Academy of Ophthalmology. Eyewear must fit snugly but comfortably and be selected based on the hazard that must be protected against. Special purposes require special attention to lenses, for example, in welding masks choose the correct filter lens shade that’s appropriate for the type of welding being done.

Ultimately, wearing the protective eyewear is the key to preventing injury. When people have more choices in protective eyewear, they tend to be more consistent in using it.

Hearing Protection

Noise from machinery, equipment, and processes like demolition are constant at many construction sites. If you’ve ever wondered just how loud common equipment on a site could be, OSHA’s pocket guide to noise protection provides context. Forklifts, nail guns, and bulldozers are just some of the noise sources that exceed OSHA’s 90 dBA permissible exposure limit.

Ear muffs and ear plugs can bring the sound down to appropriate levels. Selecting the right hearing protection must take into account other PPE being used, such as hard hats or welding gear so that all the protective equipment fits together and provides consistent protection without introducing gaps or misalignment. Liberty Safety can help you identify the appropriate protection for any application.

Body Protection

Protection for the body begins with being visible—you have to be seen to stay safe. The human body is no match for the powerful machinery everywhere on construction sites, nor does it stand much of a chance against speeding traffic in a highway work zone. High visibility gear, required under many categories of working conditions allows you to be seen.

Vests like HiVizGard™ Surveyor’s Vest or Foreman Surveyor’s Vest have pockets for radios and other day-to-day essentials. Liberty Safety offers other vests that include large hidden pockets that can accommodate work documents as well as solid front styles with sleeves.

Respiratory Protection

Breath is life, and healthy breathing demands adequate protection on the job. Gas leaks, dust, smoke, chemicals, and work around processes like abrasive blasting all pose respiratory threats. Whether nuisance masks or full body encapsulated suits are needed, the right PPE allows workers to use paints, adhesives and chemicals safely so that long-term health damage can be avoided. Liberty Safety has a range of respiratory PPE and can help you identify the right gear for your application.

Hand Protection

The hands are the part of the body most likely to be injured in a construction workplace. And often many of these injuries are highly preventable, according to Safety+Health. To give hard working hands the protection they need, choose gloves with care.

Start by looking for gloves based on the circumstances of the job. Choose a snug fit that permits dexterity for handling machines and tools. Cuts and lacerations aren’t the only concerns. Welding requires highly specific gloves, and heavy duty rubber gloves are needed for concrete work. Chemical resistant gloves protect skin from burns.

Liberty Safety has the expertise to help you match the right glove to the needs of your workforce to provide comfort, fit, and top performance. A variety of coated gloves offer cut resistance, puncture protection, and protection from chemicals appropriate to specific types of work as well as improve grip and enhance hand comfort for working with tools.

For workers in drywall, excavation, masonry, plumbing, mechanical and related trades, Liberty Safety offers these FroGrip® gloves F4920RT, F4927, F4970SD, 4729SP and many others. Use the ANSI cut resistance standards to help determine the right gloves for your tasks.

Foot Protection

For all types of construction work, the ability to walk without slipping and protected from injury is foundational. Puncture-resistant soles prevent nails and sharp objects from penetrating the shoe or boot; steel or composite toes offer protection from crush injuries resulting from falling tools, equipment, materials or machinery.

Long aprons, leggings, and other leg protection are needed for activities like welding or in situations where falling and rolling objects present a hazard.

Stable footing is the foundation of healthy working posture. Protective footwear and boots made of durable, waterproof materials provide comfort and protection as well as slip resistance.

Construction PPE has a Single Task to Perform

The right safety gear for the situation is critical. Think of your PPE as the long snapper in football.

You don’t often hear much about the long snapper, yet this special teams player is critical. Snapping the football with perfect accuracy for field goals, extra points, and punts may seem monotonous, but consistency is everything. Perfection is expected.

In construction, PPE is like the long snapper. It has one job to do protecting workers–day after day–and its reliable performance is absolutely critical. The bar is set high, for good reason: lives and good health depend on it.

Suit up for the day ahead and let PPE do its work–the single-focused, special-teams task of keeping construction workers–and site visitors–safe from injury.

Sources:

Construction and Extraction Occupations : Occupational Outlook Handbook: : U.S. Bureau of Labor Statistics (bls.gov) [construction occupations]

https://www.osha.gov/sites/default/files/publications/osha3151.pdf

https://freakonomics.com/podcast/why-does-the-most-monotonous-job-in-the-world-pay-1-million/