Working outdoors may have some perks, but when it comes to extreme winter weather, it can get uncomfortable and even dangerous.

A 2017 study by the U.S Bureau of Labor Statistics reported over 20,000 ice, sleet, and snow-related injuries. These conditions pose a significant risk to workers, indoors and outdoors, in services like transportation, agriculture, construction, and other industries where they may be exposed to environmental cold stress.

Luckily, to keep your workers safe in what’s expected to be a particularly cold winter, you can take precautions recommended by industry experts. But first, it’s important to know exactly what you are up against.

What is Cold Stress?

Cold stress is when the body cannot warm itself and maintain a normal body temperature. It occurs when extremely cold conditions drive down the skin temperature and, eventually, the internal body temperature (core temperature).

This may lead to serious health problems and may cause tissue damage and possibly death.

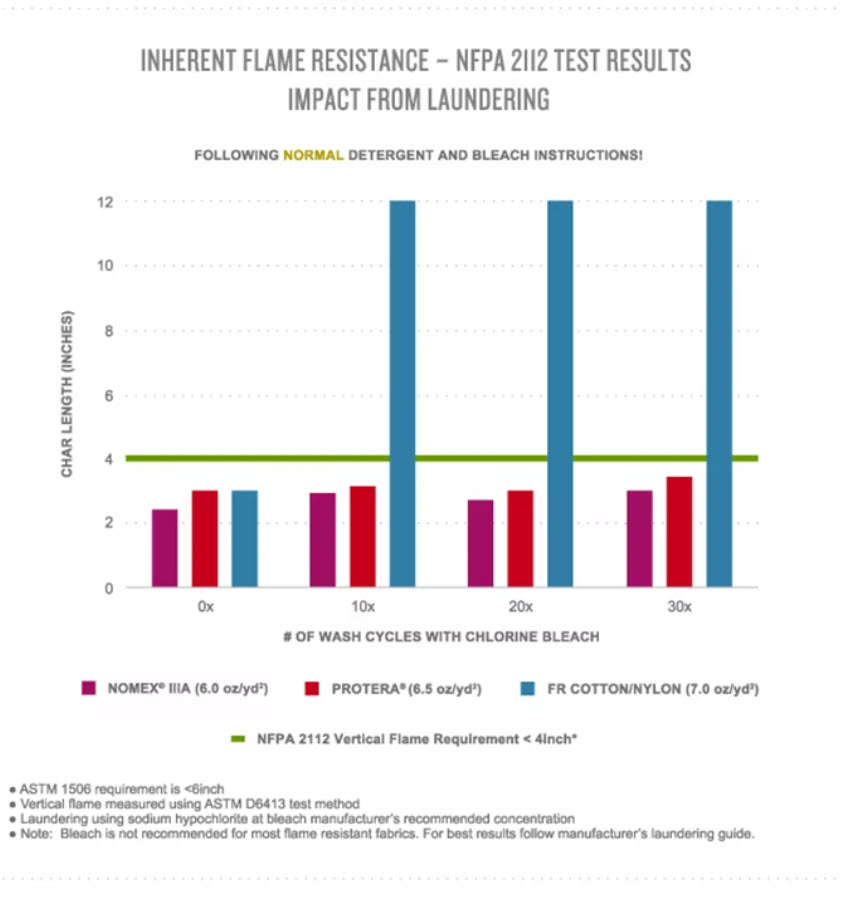

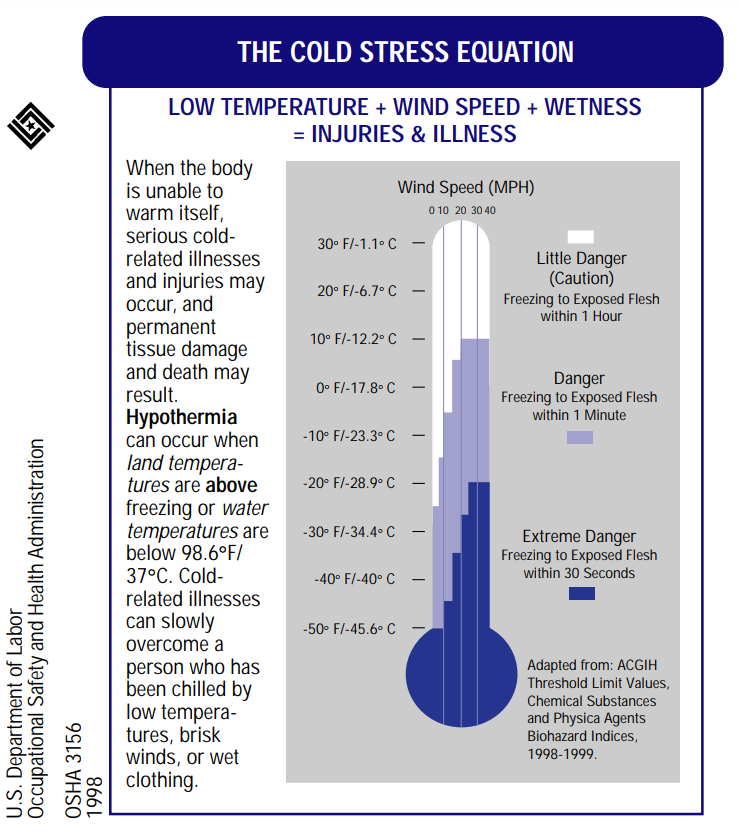

The Centers for Disease Control and Prevention (CDC) blames a combination of three elements: low temperature, wind speed, and wet conditions. The diagram below shows that each can lead to illness even at moderate temperatures.

To stay safe, those who work in extremely cold environments should follow the essential recommendations listed below.

1. Know the Danger Signs

The CDC lists four main cold-related injuries and illnesses caused by cold stress to watch out for:

Hypothermia

When exposed to cold temperatures, your body begins to lose heat faster than it can be produced. Prolonged exposure to cold will eventually use up your body’s stored energy. The result is hypothermia or abnormally low body temperature.

A body temperature that is too low affects the brain, making the victim unable to think clearly or move well. This makes hypothermia particularly dangerous because a person may not know it is happening and cannot do anything about it.

Symptoms of hypothermia can vary depending on how long you have been exposed to cold temperatures.

Early Symptoms

- Shivering

- Fatigue

- Loss of coordination

- Confusion and disorientation

Late Symptoms

- No shivering

- Blue skin

- Dilated pupils

- Slowed pulse and breathing

- Loss of consciousness

Frostbite

Frostbite is an injury to the body that is caused by freezing. Frostbite causes a loss of feeling and color in the affected areas. It most often affects the nose, ears, cheeks, chin, fingers, or toes.

Frostbite can permanently damage body tissues, and severe cases can lead to amputation. In extremely cold temperatures, the risk of frostbite is increased in workers with reduced blood circulation and among workers who are not dressed properly.

Symptoms of frostbite include:

- Reduced blood flow to hands and feet (fingers or toes can freeze)

- Numbness

- Tingling or stinging

- Aching

- Bluish or pale, waxy skin

Trench Foot

Trench foot, also known as immersion foot, is an injury of the feet resulting from prolonged exposure to wet and cold conditions. Trench foot can occur at temperatures as high as 60 degrees Fahrenheit if the feet are constantly wet.

Injury occurs because wet feet lose heat 25-times faster than dry feet. Therefore, to prevent heat loss, the body constricts blood vessels to shut down circulation in the feet. Skin tissue begins to die because of a lack of oxygen and nutrients and due to the buildup of toxic products.

Symptoms of trench foot include:

- Reddening of the skin

- Numbness

- Leg cramps

- Swelling

- Tingling pain

- Blisters or ulcers

- Bleeding under the skin

- Gangrene (the foot may turn dark purple, blue, or gray)

Chilblains

Chilblains are caused by the repeated exposure of skin to temperatures just above freezing to as high as 60 degrees Fahrenheit. Cold exposure causes damage to the capillary beds (groups of small blood vessels) in the skin.

This damage is permanent, and the redness and itching will return with additional exposure. The redness and itching typically occur on cheeks, ears, fingers, and toes.

Symptoms of chilblains include:

- Redness

- Itching

- Possible blistering

- Inflammation

- Possible ulceration in severe cases

2. Stick to a Work/Warm-up Schedule

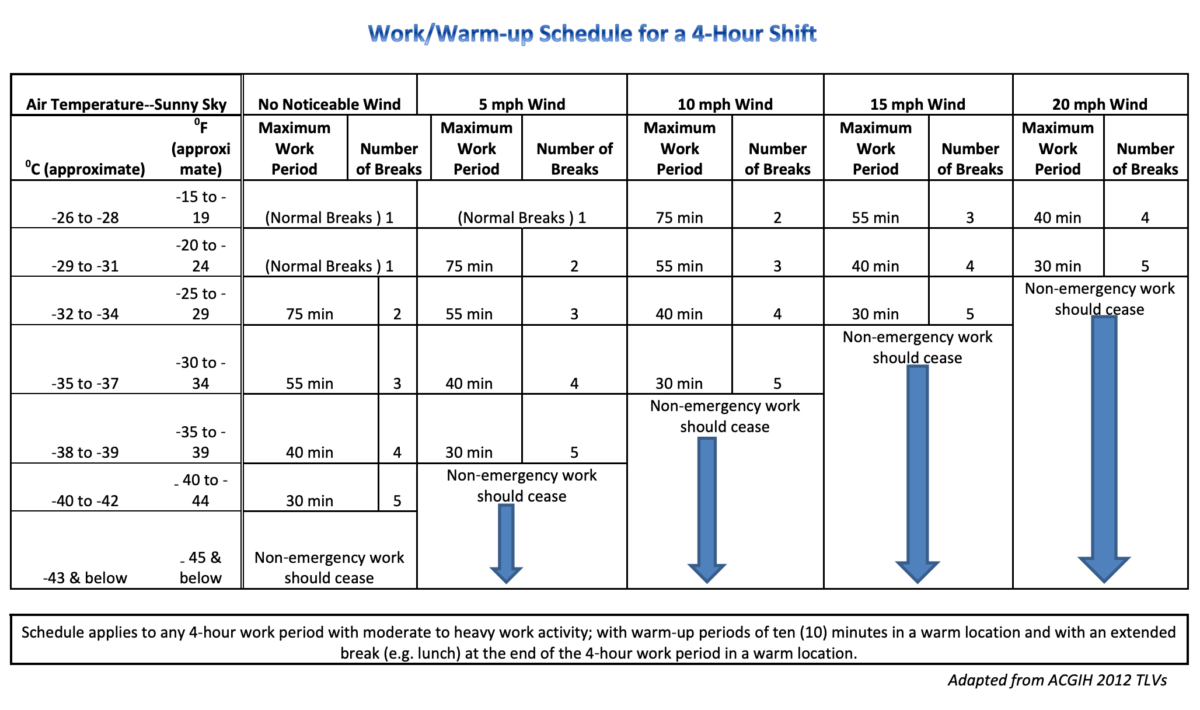

Worksite regulations specifically target cold stress because of the serious physical harm or even death it can cause to workers.The American Conference of Governmental Industrial Hygienists (ACGIH) developed the “Work/Warm-up Schedule for a 4-hour shift” to address the dangers. It considers air temperature and wind speed to provide recommendations on scheduling work breaks and ceasing non-emergency work.

The National Institute for Occupational Safety and Health (NIOSH) also advises moving into warm locations during work breaks and limiting the amount of time outside on extremely cold days.

They recommend workers should also carry cold-weather gear, such as extra socks, gloves, hats, jackets, blankets, a change of clothes, and a thermos of hot liquid. And first aid kits should have a thermometer and chemical hot packs.

3. Dress in Insulated Layers that Keep You Dry

Workers need to ensure they wear warm clothing layers designed using cold and wet weather-appropriate materials.

As a rule of thumb, protective clothing should be selected according to temperature, environmental conditions, activity duration, and the intensity level of the job that will be performed.

This is because the sweat level created when you work affects the best amount of layering you should have. In general, several layers are better than a single thick garment so that workers can remove layers if they begin to sweat or add layers if taking a break or performing less strenuous tasks.

It’s advised to wear at least three layers of loose-fitting clothing for better insulation.

- An inner layer of thermal wear, wool, silk or synthetic (polypropylene) to keep moisture away from the body.

- A middle layer of wool or synthetic to provide insulation even when wet.

- An outer wind and rain protection layer that allows some ventilation to prevent overheating.

4. Protect Your Most Vulnerable Body Parts

Typically, PPE is considered the last line of defense for worker protection. However, when it comes to cold environments, clothing and PPE play a significant role in protecting potentially exposed skin.

Employers must provide PPE when required by OSHA general standards. But, there is no official OSHA requirement for employers to provide workers with ordinary clothing or other items used solely for protection from the weather.

Despite that, many employers provide their workers with winter weather gear like winter boots, jackets, thermal pants, and gloves, as shown below.

When selecting PPE, NIOSH warns workers to avoid a tight fit for outdoors because it can reduce blood circulation. They also suggest staying away from any clothes that may limit your range of motion and result in a hazardous situation.

“You need to be aware that having extra PPE on may restrict some of your movements, so you need to be more careful,” Brenda Jacklitsch, a health scientist for NIOSH, said in a Safety + Health magazine article.

Winter Work Requires Working Smart

For workers in cold environments, there is little room for error when it comes to staying safe. But even though there are additional precautions to take, it doesn’t have to slow productivity.

NIOSH recommends that employers keep things moving by implementing a cold-related illness and injury prevention program. Their website provides recommended and appropriate controls that are practical and appropriate for very cold work environments.

By identifying and minimizing risks and ensuring the most appropriate gear is available, you and your workers will stay warm, dry, and safe throughout the season.

When it comes time to find the best selection of PPE for cold environments, Liberty Safety can help. Contact us to learn more about our line of personal protective equipment.