When was the last time you checked in on how your team felt about their PPE?

Listening to your workers’ concerns and thoughts about the protections they wear at work could be the difference between compliant and non-compliant. By initiating the discussion, you’ll also increase understanding and demonstrate they are an integral part of the company.

The opposite is also true. Leave the workers out, and you may run the risk of them simply not caring.

A 2020 survey from the EHS Daily Advisor backs this up and reports that noncompliance is more likely when workers feel they have no say regarding the PPE they wear. In addition, the survey revealed that:

- 5% flat out refuse to wear PPE

- 58% didn’t know the value of the PPE they wear

- 72% regularly witness other workers improperly wearing PPE (or not wearing it at all)

Before your workforce becomes one of those statistics, it’s a good idea to listen up. Here are six common things you are likely to hear when you initiate that conversation:

1. My PPE doesn’t fit well (it runs small or large, or isn’t comfortable)

At its core, PPE is equipment that needs to fit well and be worn every time to minimize exposure to various hazards. PPE obviously cannot be effective if it is NOT worn and can even have dire consequences if it fits improperly.

OSHA notes that well-fitting, comfortable PPE encourages employee use. Because most protective devices are available in multiple sizes, you can take the time to select the proper size for each employee.

Because PPE isn’t one-size-fits-all apparel, PPE manufacturers will often supply businesses with a selection for fit testing. It’s an excellent opportunity to get honest worker feedback and bring them into the selection process before you buy.

2. This PPE makes me too hot or too cold

When a worker is feeling too hot or too cold, it’s only natural it will impact their productivity.

Extreme heat requires providing workers cover and cooling technology. Most workers like wearing light, breathable clothing that wicks away sweat to keep them cool.

Popular among most outdoor workers are items that offer shade or prevent heat build-up like:

Freezing temperatures require clothing and PPE to play a significant role. Necessary items to safeguard workers should include:

Some workers report that the extra PPE worn during the winter months can restrict movement. This is when listening to what they have to say and addressing it with PPE choices that work for them, as well as the appropriate training, is critical.

3. My hard hat, work gloves (or other PPE accessories) don’t fit!

PPE accessories like hard hats and gloves are designed specifically for particular applications. But to be effective, they must have an exact fit.

Caption: A hard hat that provides a suspension system ensures the hat stays in place.

Hard hat: OSHA has stringent rules about wearing head protection. Part of that is fit.

Most hard hats on the market come in various sizes with adjustable headbands. According to OSHA, hard hats should allow the right clearance between the shell and the suspension system. It’s a factor that impacts ventilation and helps distribute impact. It shouldn’t slip, bind, fall off or irritate the skin.

Caption: It’s important to get a glove that not only fits but also offers the protection required.

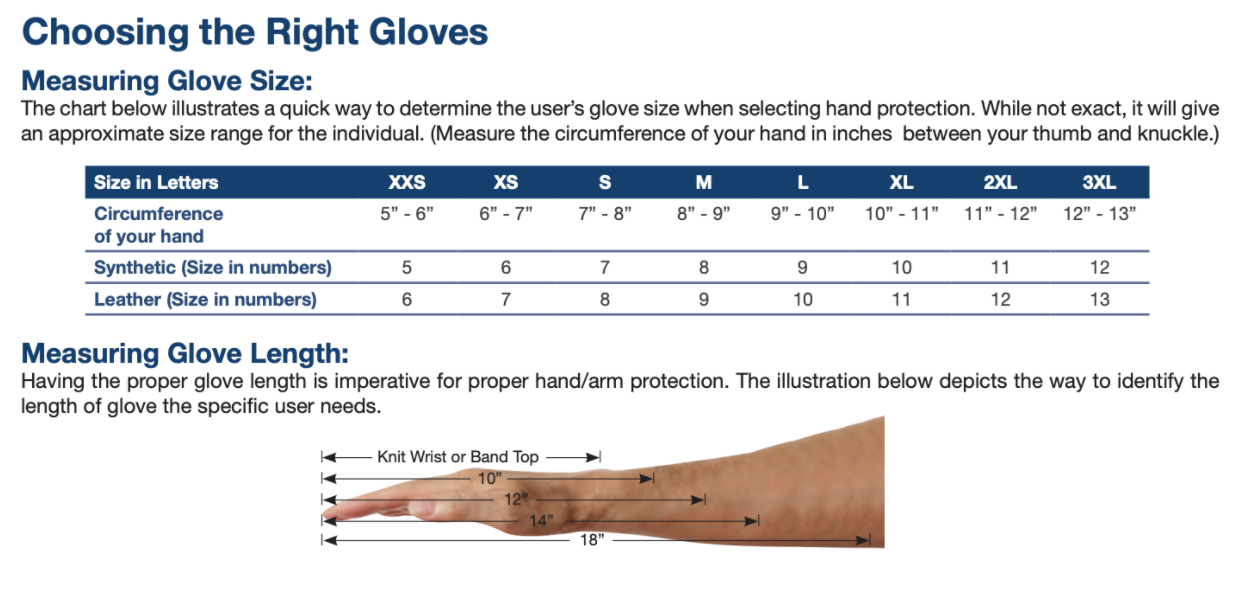

Work Gloves: For optimum hand protection fit is crucial. Too big and the glove may become a hazard by being caught in the machinery. And, if a glove is too small, it can limit movement and increase the likelihood of non-compliance.

To ensure the best sizing, measure the hand around and across the palm, excluding the thumb. Use the sizing chart and recommendations below to get the most accurate measurements.

For more information on specific requirements for PPE accessories like work gloves and hard hats, search the National Institute of Occupational Safety and Health (NIOSH) PPE database for industry experts that can help. It’s a resource that serves as a comprehensive research tool for Federal regulations and consensus standards on PPE.

4. Why do I have to wear this? I don’t think it’s effective in protecting me.

Answering the question of “Why?” is an important step to creating an understanding of the need to wear PPE on the job.

A recent survey from California Polytechnic State University was conducted on thirty-three (33) random construction workers in California to better understand issues with PPE and reasons for non-compliance. Of those respondents surveyed, the most common reason, second only to gear being uncomfortable, was that they thought it was not necessary at certain times even when required.

Addressing the importance of using PPE and the natural and system consequences of not complying is critical. It’s an essential part of training workers when introducing new PPE and is also necessary for ongoing training.

Without meaningful PPE training, you are not only endangering your workers, but you could face a hefty fine from the Occupational Safety and Health Administration (OSHA).

OSHA requires all employers to train employees on the PPE they’ll be using for their job. Each person needs to know when it is necessary and what kind is essential.

They also recommend an ongoing PPE program that addresses the hazards present; the selection, maintenance, and proper use of the PPE. They suggest monitoring the program to ensure its lasting effectiveness too.

5. I don’t like how this looks on me

In a Georgia Southern University examination of compliance with PPE among wastewater workers, 51.8% indicated they felt their coworkers would make fun of them for wearing personal protective equipment.

It’s a classic example of how what other workers think influences compliance. It’s also evidence that style can and should be a significant consideration when choosing PPE.

PPE that performs without giving up comfort and aesthetics is in high demand. Luckily, the industry has come a long way in improving the overall look of individual items to meet those demands.

Caption: Offering a varied selection of great-looking gear helps encourage compliance with health and safety regulations

As the wastewater worker survey revealed, employees are likely to have greater motivation to work if their PPE is comfortable and looks good on.

6. I don’t really know how to wear this equipment

Just like answering the “why” question is essential, so is answering the “how” question.

That means each employee who must use PPE needs to know:

- How to properly don on, don off, adjust and wear the PPE

- The limitations of the PPE

- Proper care, maintenance, useful life, and disposal of PPE

OSHA recommends employers make sure that each employee demonstrates an understanding of the PPE training and the ability to properly wear and use PPE before they are allowed to perform work requiring the use of it.

Workers need to know how to handle PPE safely when removing it from the body to avoid contaminating themselves and surfaces nearby. Training employees on how to don and doff PPE and know the equipment’s limitations must be part of the process.

Worker Engagement Builds Safety

Giving your employees a say in selecting PPE ultimately leads to a healthier and safer workplace. That type of worker engagement builds an influential safety culture and encourages active participation in it.

At Liberty Glove and Safety, we want to help. We offer a large and varied range of high-quality brands that make the essential PPE you need. For more information on our line of personal protective equipment, get in touch today!