The oil and gas industry touches many aspects of modern life, from fuel used to transport people and goods to materials used in the production of goods that surround us every day. Work involved in exploration, drilling, production, processing, refinement and transportation involves high-risk activities which often must be conducted in extreme conditions.

Hours are long and the workplace is typically hazardous for oil and gas industry workers. Along with engineering processes for greater safety and rigorous training in a wide range of safety practices, appropriate PPE is an important step in protecting the health and safety of workers.

We’ll take a look at the hazards specific to the upstream and downstream aspects of the oil and gas industry and the types of PPE that can help mitigate those risks and protect workers.

Workplace Hazards in the Oil and Gas Industry

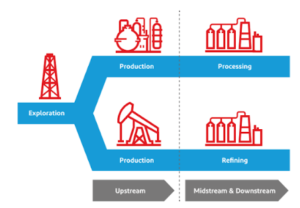

Overall, the oil and gas industry breaks down into two distinct parts, upstream and downstream.

Source: DuPont

Upstream refers to the activities related to exploration and production. Exploration includes all the tasks related to identifying the places to drill, conducting surveys, and handling various types of rights involved in the process. Production deals with getting the oil and gas out of the ground through drilling and hydraulic fracturing (fracking).

Downstream refers to the refining and processing of oil and gas. The transportation and storage processes that support the processing and distribution phases are sometimes termed midstream activities or grouped with downstream activities.

Looking at the industry as a whole, the jobs involved are different in upstream and downstream, as are the specific hazards that workers are exposed to, yet some hazards are common throughout.

- Fire and explosions

- Machinery and heavy equipment

- Chemicals, including hydrogen sulfide gas

- High pressure lines and equipment

- Fatigue

- Vehicle collision

Upstream Hazards in the Oil and Gas Industry

Workers in upstream oil and gas perform many high-risk tasks in their jobs and are frequently exposed to several extreme workplace hazards. Off-shore drilling produces about 30% of the world’s crude oil, and for those working on oil rigs or drilling platforms, a combination of conditions make the work extremely challenging.

Hours are long, often 12-hour shifts that operate around the clock, and the tasks are physically demanding. Extreme weather conditions can arise at any moment and further complicate the work at hand. All this, plus human error, equipment failure, and external conditions can potentially lead to injury.

Flash fires are a significant hazard as are explosions from the well itself or explosion of flammable materials involved in the drilling process. Oil and gas are flammable, as are some of the chemicals involved in the drilling operation.

Work at times takes place in narrow or confined spaces, including storage tanks, mud pits, and areas around the wellhead, creating an ignition hazard and increasing the risk of suffocation.

Equipment and rotating machinery involved in the extraction process present the hazard of worker injuries from being struck by, caught between or caught in machines and heavy equipment. Burns and blunt force injuries are also common, as well as injuries from being struck by debris.

One of the specific risks of upstream oil and gas production is that of breathing in hydrogen sulfide gas, which may be released as part of the drilling process. In small concentrations, it can be harmful and cause irritation to the eyes and respiratory system, but in larger concentrations it can be deadly.

OSHA-NIOSH’s Hazard Alert describes the challenges related to hydraulic fracturing, or fracking. Exposure to dust with high levels of respirable silica released in this process can lead to lung disease.

Downstream Hazards in the Oil and Gas Industry

Collectively, the activities of refining, transporting, storing, marketing and selling are part of the downstream process. Separating the crude oil into various products involves exposure to hazardous emissions and VOCs along with the hazards of working with pressure vessels, pipelines, and compressors.

Transporting crude and refined products involves a variety of transportation methods–tankers, barges, and trucks.

Operational tasks include maintenance technician jobs including welding steel and maintenance of compressors, pumps, heat exchanges and other systems. Additional hazards include confined spaces and high pressure lines and equipment

PPE to Protect Oil and Gas Workers

Keeping workers in the oil and gas industry safe requires comprehensive and regular safety training as well as the development and implementation of safe practices. OSHA’s Job Safety Analysis Process can be used to help workers identify hazards at the worksite and find solutions, such as implementing safe practices for fall protection, fire protection, electrical work, emergency response and other concerns.

The correct use of appropriate PPE is an important part of establishing workplace safety. Typical PPE requirements for oil and gas workers, in both upstream and downstream jobs, includes hard hats, safety glasses, and hearing protection to handle a wide range of exposures. Boots should be chosen to provide crush protection, insulate against shock, and give secure footing to reduce slips and falls. Respiratory protection is vital, and needs to be selected depending upon the particular conditions such as exposure to hydrogen sulfide gas or crystalline silica, or air that is otherwise unsafe to breathe.

Across all aspects of the oil and gas industry, workers need protection from fire, chemicals, and machinery–gear that provides safety for the hands and body during all types of activities. Gloves and coveralls fill this role.

Gloves

Hand protection is a must for both upstream and downstream workers. Choose gloves that are designed to meet the demands of cut resistance and chemical resistance to protect hands against oils, abrasion, chemicals and cuts. Materials like neoprene, nitrile, vinyl, rubber protect hands from chemical and liquid hazards. Specialty gloves offer protection from crush, vibration, and other hazards.

SHOWA KV660 Chemical Protection Gloves defend against a broad range of hazards as well as oils. Along with ANSI cut level 2 protection, this seamless knit liner gloves are triple-dipped with a PVC coating and reinforced with a Kevlar® liner. The rough surface of SHOWA KV660 gloves offers a good grip and high abrasion resistance. And the SHOWA KV660 maintains its barrier to hazards even after multiple washes.

SHOWA 240 Cut Resistant Gloves protect against cuts and burns, having an ANSI Cut Level A3 rating and Level 2 arc flash defense rating. They protect hands from flames, flashes and sparks as well as cuts. The SHOWA 240 Cut Resistant Gloves are made of a seamless knit and have a Kevlar® liner and sponge neoprene palm coating for extra grip; they’re comfortable, flexible, and easy on the skin even when worn for long periods of work. A Level 5 EN 420 Dexterity rating ensures control and precision when working on small-scale projects.

Coveralls and Body Protection

Workers in upstream and downstream activities require specialized protection to meet the demands of their roles in the industry, whether working on a drilling platform or maintaining pipelines.

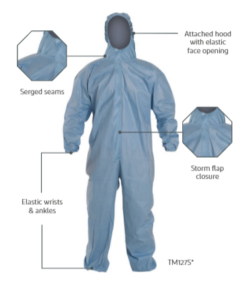

High performance coveralls help protect upstream and downstream workers from flash fires and an array of chemical exposures. Coveralls like the DuPont™ ProShield™ 6 SFR are worn over a primary flame-resistant garment. The ProShield™ 6 SFR provides a lightweight barrier against oils and greases, non-hazardous particles, and secondary flame-resistant protection. With an attached hood, elastic waist and attached sock ensure a secure fit with a front storm flap.

To simultaneously protect workers against chemical hazards and flash fires, Tychem® 2000 SFR is made of a unique fabric technology that provides both chemical and secondary flame protection in a lightweight garment, intended to be worn over primary flame resistant garments.

In the event that a flash fire occurs, these coveralls won’t ignite and won’t contribute to additional burn injury if appropriate flame-resistant personal protective equipment, such as DuPont™ Nomex®, is worn beneath. The Tychem® 2000 SFR fabric doesn’t char like traditional secondary flame resistant technologies. Instead, it was designed to shrink away from flame – without burning.

Taped seams provide strong chemical resistance against heavy liquid splashes. A sewn seam is covered with a strip of compatible chemical-resistant material through heat sealing. The attached respirator-fit hood, lined with ProShield® 6 SFR fabric, has elastic around the face opening. A storm flap, which can be sealed by the wearer with an adhesive strip to prevent intrusion, covers a strong zipper. Integrated socks are composed of garment material and elastic at the wrist opening offers a tighter fit.

Full-body garments like the DuPont™ Tychem® 6000 FR coveralls provide triple hazard protection–from chemical splashes, flash fire, and electric arcs–in a single-layer garment. The Tychem® 6000 FR combines the chemical protection of Tychem® with the thermal/arc protection of Nomex®.

The Tychem® 6000 FR provides 30 minutes of protection from >180 chemicals, is certified to NFPA 1992, and has an arc rating of 15 cal/cm2 Ebt, which exceeds the NFPA 70E Hazard Risk category 2 requirement.

PPE Meets the Challenges

Every day, workers in the oil and gas industry confront an array of hazards; EHS Daily Advisor presents the top hazards in an infographic. Protecting workers doing hazardous jobs in extreme conditions demands PPE that performs consistently to meet and beat the challenges.

Source: EHS Daily Advisor

Don’t take chances when the risks are already high. Work with an experienced supplier who can provide the industry’s best protection products and who willingly shares their deep expertise to ensure your teams are equipped with the appropriate gear.

As a preferred vendor partner with DuPont and Showa, Liberty Safety has the technical resources to answer your questions and help you keep your workers safe, day in and day out.