Automotive paint does more than create pleasing appearance, it’s a complex technology that protects the metal while creating the chosen finish. For those who work in automotive paint environments, it’s also a potential health threat, which is why choosing the right PPE is critical.

Automotive paint shop workers may be employed in body shops, dealerships, and automotive repair shops as well as factories; they face exposure to similar hazards involved in mixing and applying paints and chemicals that are often toxic or hazardous.

The paint they spray is typically a mixture that includes not only paint but also thinner, hardener, and a catalyst formulated to suit the substrate and other characteristics of the desired finish. While OSHA regulated operations and NIOSH outlines best practices, extreme care and conscientious use of PPE is needed to protect the immediate and long-term health of workers.

Hazards and Exposures on the Job in Automotive Painting

The routine operations involve a host of chemicals that pose risks related to both acute and long-term exposure, as well as activities that produce dust and particles that are harmful when inhaled. Work in autobody repair and painting exposes workers to a variety of hazards, both physical and chemical. OSHA provides detailed explanations and guidelines for specific hazards within the automotive painting industry. Several common hazards include:

Airborne Particles

Grinding and sanding to remove old finish or as part of the painting process puts dust and particles into the air. This paint and primer dust may have hazardous characteristics that lead to irritation in the respiratory system. Sandblasting, if it is used, also releases silica into the air.

Noise

Fans, blowers, and sanders are all typically involved in the painting process in a body shop contributing to the basic noise level. Sanders and spray booth fans run at about 80dB; air blowers may range up to 90 or 100dB, depending on the type and pressure. Hearing damage occurs from exposure to excessive noise in two ways–particular events of loud sounds, and the duration of exposure to elevated noise levels. Generally, the acceptable noise level limit for eight hours would be about 85dB, and that duration before permanent damage occurs decreases with an increase in noise level. Specific tools and equipment can produce noise at significantly higher levels.

Unlike a muscle that can be strengthened, you can’t “toughen up” your hearing by repeated exposure to loud noise. Hearing loss builds over time and is not reversible.

Physical Injury

Working with cutting tools, sheet metal as well as welding operations presents ample opportunity for injuries. Flying metal fragments can cause eye injuries; welding operations can cause burns and eye damage. Oil and grease can lead to slips and trips that result in falls; and repetitive stress injuries from poor ergonomics when handling tools.

Vapors and Fumes – working with volatile organic compounds that give off vapors

These gases can damage the respiratory system and other problems. VOCs are released by paints, fillers, and solvents. Metal fumes enter the air from welding and cutting.

Isocyanates

Automotive paints are specially formulated for their purpose and typically contain a resin or binder, pigment, solvent, and other additives. The resins in these paints are often polyurethanes; isocyanates are essentially, the raw materials that compose polyurethanes.

NIOSH describes isocyanates as “powerful irritants to the mucous membranes of the eyes and gastrointestinal and respiratory tracts.” Exposure builds over time and they cause damage to the eyes and skin. Repeated exposure can lead to sensitization and severe illness including work-related asthma. Products containing isocyanates must be handled carefully to avoid health problems and introduce a specific set of cautions and hazards. The damage is cumulative, and the body does not get rid of these once they are taken in.

An introductory guide is offered by NIOSH that reviews a range of chemicals and helps workers to understand the potential health risks associated with each one.

PPE to Address the Hazards

Exposures of all types in this industry tend to be cumulative, whether the exposure is to loud noises or chemicals. The actions you take today will affect not only your health tomorrow, but your length of life and the quality of life you’ll experience in the years ahead. Careful attention to best practices also helps prevent exposing your family to the effects as well.

DuPont™ recommends using the 4P method for assessing risk in the workplace.

Earplugs and earmuffs that are worn all day preserve hearing and address the cumulative effect of noise from fans, paint booth operations, blowers and sanders.

Respirators and face masks protect the lungs and respiratory system from particles, vapors, fumes, and chemicals that can be inhaled. Their use is critical for protecting health, and required in accordance with regulations for chemicals used and paint booth operating standards. OSHA provides detailed guidance for the use of various types of protective respiratory gear that is beyond the scope of our discussion here.

While awareness of an odor can be an indicator of the presence of a potentially harmful chemical, some chemicals are odorless and cannot be detected by smell. Frequent exposure to certain other chemicals can diminish the sense of smell that would help indicate their presence.

Gloves provide improved grip while protecting the hands against multiple types of injuries. When the hands are exposed to harsh chemicals burns can result, and toxic chemicals can readily enter the bloodstream through the skin. The proper gloves for full dexterity and also protect against cuts and abrasions when working with cutting tools and metal.

A4938 X-GRIP® gray polyurethane cut resistant gloves

Constructed with a 13 gauge salt and pepper HPPE shell, polyurethane coated palm and fingers, these gloves offer ANSI level A2 cut resistance, breathability, and provide all day comfort.

Coveralls and full-body protective clothing efficiently prevent chemicals from coming in contact with the skin. They also help paint booth workers to produce the best quality coating applications by preventing the lint or dust from clothing, which could damage the surfaces being painted, from entering the spray booth.

DuPont™ Personal Protection is designed with unparalleled expertise and taps into a broad portfolio of technical solutions to meet or exceed global protection standards. For paint shops, Tyvek® 400, Tyvek® 800, and Tychem® 2000 coveralls offer specialized protection and are available through Liberty Safety to meet the demands and hazards for these task-specific jobs.

DuPont™ Tyvek® model TY800

Coverall with hood has serged and over-taped seams and elastic thumb loops. It has elastic wrists, ankles and face and an elastic waist (glued-in), a self-adhesive Tyvek® storm flap and a self-adhesive chin flap. Garments resist low-concentration, water-based inorganic chemicals and provide an effective barrier against many water-based inorganic chemicals in low concentration, as well as particles down to 1.0 micron.

DuPont™ Tyvek® 400 TY120

Coverall with comfort fit design. This style has a collar, elastic waist, storm flap, open wrists and ankles, and serged seams. These garments offer durability and comfort along with softness and breathability. They repel water-based liquids and aerosols and fine particles and fibers down to 1.0 micron.

DuPont™ Tychem® 2000

Coverall includes a standard fit hood, serged seams, and storm flap in addition to elastic wrists and ankles. A lightweight and durable fabric, Tychem® 2000 fabric provides at least 30 minutes of protection against >40 chemical challenges. Tychem® 2000 is used for light splash protection in a variety of industrial environments.

Advantages of Tyvek® and DuPont™ Products

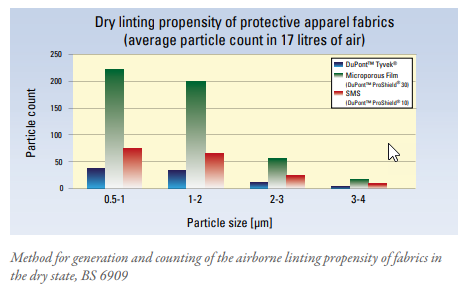

Tyvek® brings key characteristics into play. Coveralls are anti-static treated to minimize dust entering from outside the spray booth. The specific structure of Tyvek® is stable, durable, and low lint, suitable for settings that demand high air purity. The low lint characteristic of Tyvek® keeps spray booths free of lint and dust so that the best quality finish can result.

The unique structure of Tyvek® material offers a high degree of protection against airborne particles and many water-based inorganic chemicals. As the nonwoven structure of the material forms a multi-layer barrier, its barrier performance will remain intact even if the outer layers become damaged in places. Beyond the durability of the material—Tyvek® is highly resistant to abrasion and tearing—it is also lightweight and soft, as well as permeable to both air and water vapor, providing a high level of comfort. For specific types of paint or exposure, the protection provided by Tyvek® must be reinforced or enhanced with other accessories, such as those available in the Tychem® range. Some types of paint work present risks not only when applying the paint, but also when preparing the paint or cleaning tools, using solvent washers, and so on. For all potentially hazardous tasks, DuPont™ suggests its range of lightweight and effective Tychem® accessories.

Practicing Protection

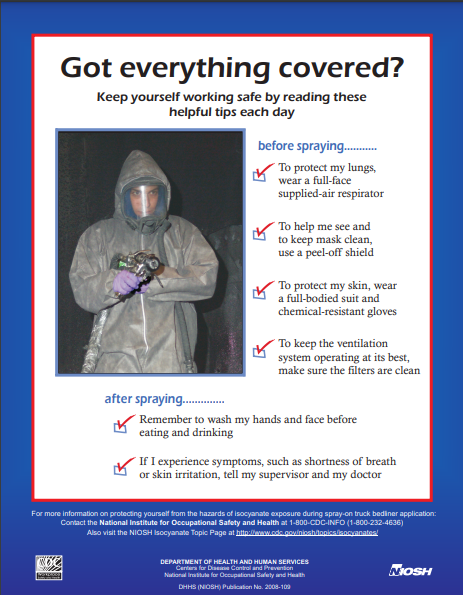

NIOSH sums up sound PPE practices for paint application in their poster:

Source: NIOSH

Safety and health are protected day by day through effective use of appropriate gear. As a preferred vendor partner with DuPont™, Liberty Safety has a wide range of DuPont™ products and a technical support team to help you make a wise selection for your application.